Characteristics of charcoal machine production and safety issues in the carbon production process

With the continuous enhancement of social environmental awareness, energy saving will be the theme of the future development of society. Charcoal machines not only use agricultural and forestry wastes as raw materials for production, but also the production process is smoke-free, dust-free and pollution-free. The produced mechanism is in the process of burning charcoal fuel. It will not generate harmful gases, and it is a good equipment that saves energy from raw materials to processing to finished products.

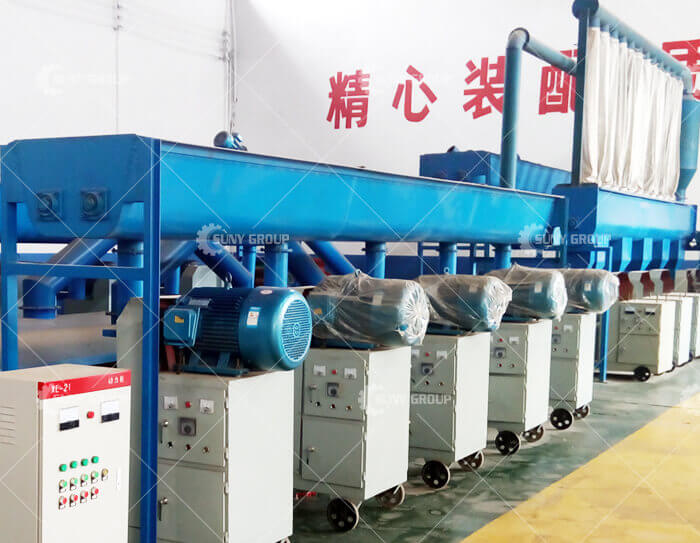

1. The charcoal machine has the characteristics of reasonable design, reliable manufacturing quality, simple structure, convenient operation, small size, less land occupation, labor saving and electricity saving.

2. The designed fully automatic control electric heating device can randomly adjust the dry humidity of the material to ensure the stability of the discharge molding and improve the work efficiency.

3. The main parts of the charcoal machine are specially treated with wear-resistant materials, so it can be continuously pressed for production and is durable.

4. The three bearings of the old movement are changed to four, which increases the stability and durability of the machine.

5. Change the old oil-coated lubrication to oil-immersed lubrication. As long as there is no shortage of oil, it can be used for many years.

6. Increase the screw pitch and increase the feed volume, thereby greatly increasing the output.

7. The structure of the forming cylinder is improved, the friction between the machine and the raw material is reduced, and the density of the mandrel is increased.

The first potential safety hazard in the production process of the charcoal machine is electricity. The rod forming equipment of the charcoal machine uses an electric motor, which uses 380V electricity. The body is made of steel with good heat dissipation performance, but it also has Conductivity. Many operators did not notice this when a fault occurred, and accidentally touched it to cause an electric shock. The solution to this kind of safety hazard is to install a leakage protection device at the power source, or install an air protection switch at the bus to avoid accidental electric shock. Secondly, a grounding device must be installed on the body of the motor to avoid leakage.

The second major safety hazard that is likely to occur in the production of charcoal machines is fire. The charcoal machine carbonization furnace is made by carbonizing the formed carbon rods at high temperature. Generally, there will be sparks in the center hole when it comes out. The sparks need to be poured out and cooled. Do not stack them indoors, otherwise it will easily cause fire.

The charcoal machine may have other safety hazards during the production process. The operator needs to be careful all the time during the operation and operate with a serious and careful attitude. Do not be careless. Safety production is more important than Taishan. Good charcoal machine operating habits It is a prerequisite to ensure safe production.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231