Principle Advantages of Waste Tire Pyrolysis Plant

With the continuous development of the economy, the number of automobiles continues to grow, and the production of tires is also increasing rapidly. Tires are made of non-melting or refractory polymer elastic materials. If the macromolecules of these materials are decomposed to the extent that they do not affect the growth of plants in the soil, it will take hundreds of years. The method is not suitable for waste tires. There are more and more waste tires, which are causing serious "black pollution" to the earth and posing great challenges to environmental protection.

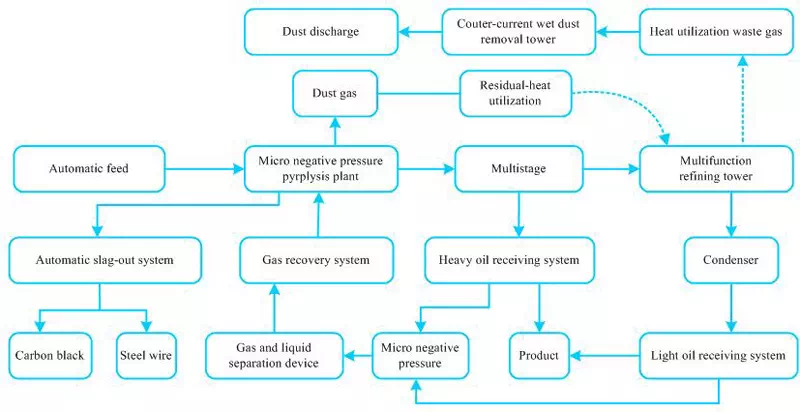

The thermal cracking equipment developed and manufactured by SUNY GROUP adopts the "micro-negative pressure thermal cracking" technology to process waste tires to produce four products: fuel oil, carbon black, and steel wire. Different from traditional oil refining, in the cascade recycling of waste tires, thermal cracking is to reduce the amount of waste tires and use them harmlessly under the premise of meeting environmental protection requirements. The pollution problems will be minimized by upgrading technology, innovating processes, installing environmental protection facilities and other means.

The basic process of pyrolysis and refining of waste tires:

Put the waste tires into the pyrolysis axe, heat up, dehydrate, then heat up, the tires melt and then gasify, condense through the condenser, separate in the separator, vibrate and filter to obtain liquid tire oil.

In terms of environmental protection treatment, general oil refining equipment only has simple water treatment. SUNY GROUP tire cracking equipment uses professional deodorization equipment to deal with odors, and uses desulfurization towers to deal with smoke and dust, which can meet the conditions of environmentally friendly emissions. The tail gas is treated by environmentally friendly waste tire refining equipment. Finally, only the combustible gas is returned to the furnace for combustion through the circulating heating system to provide heat energy, and after combustion, it will be treated again by the desulfurization tower before being discharged, which meets the international environmental protection requirements.

Advantages of new pyrolysis equipment:

1. The equipment adopts the top technology in the world - zero stripping technology. During the decomposition process, there is no need to use a special process to separate the steel wire from the rubber for a second time. This operation plays a key role in reducing energy consumption, thereby reducing capital investment. To a certain extent, the increase in economic benefits has been enhanced.

2. In order to effectively ensure that the gas does not escape during the production process and improve the efficiency of thermal cracking, the thermal cracking adopts a micro negative pressure process technology, which has the advantage of fundamentally eliminating the unsafe hidden dangers caused by gas overflow.

3. During the production process of the equipment, after the rubber is thermally cracked, most of it becomes liquid oil, and a small amount of flammable gas is circulated as the fuel for the pyrolysis furnace. Thus, the thermal energy supply of the pyrolysis furnace is ensured, the waste gas emission is reduced, and the economic and environmental benefits are improved.

4. The equipment design conforms to international standards, with compact structure, scientific and efficient production line design, safe and stable operation, strong processing capacity, and appropriate and reasonable collocation of various systems, which have positive significance for improving work efficiency, reducing energy consumption, and protecting the ecological environment.

As a professional manufacturer of solid waste recycling equipment, SUNY GROUP not only has tire cracking equipment, but also has tire rubber powder particle recycling production lines. If you are interested in the recycling of scrap tires, you can contact us directly for consultation, and we will reply you in time. Detailed solutions.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231