System That Handle Lithium-Ion Battery Electrode Scrap

With the popularity of new energy vehicles, lithium-ion batteries have been widely used as their main energy supply devices. However, with the decommissioning and replacement of batteries, a large amount of discarded lithium-ion battery electrode materials are generated, and how to efficiently recycle these electrode materials has become an important task. To address this challenge, Suny Group has developed a professional lithium-ion battery electrode waste treatment system designed to provide sustainable resource recycling solutions.

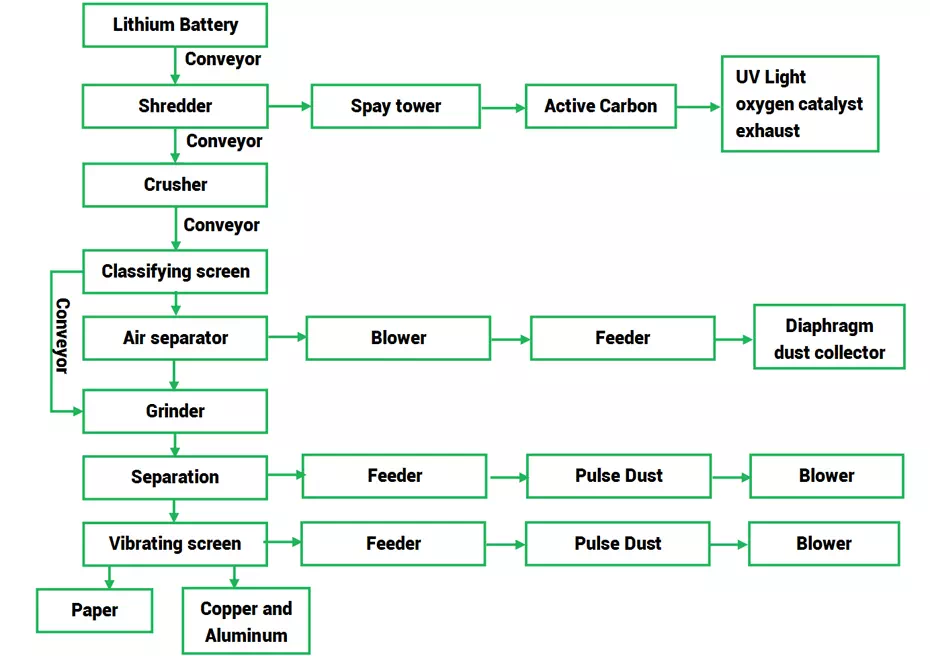

The system uses a series of processes to ensure accurate classification and efficient extraction of electrode materials. The following is the main process flow of the system:

Discharge treatment: Use professional discharge devices to control the discharge of battery modules. The purpose of this step is to reduce the risk of the battery and ensure its safety during subsequent handling.

Preliminary crushing: Use an adjustable-strength crusher to crush lithium batteries into pieces ranging in size from 5 to 20 mm. Such crushing size can facilitate subsequent separation and grinding processing.

Lithium battery recycling process

Magnetic separation: The strong DC magnetic field is used for the main separation work, and the fragments containing copper, aluminum and other metal particles are adsorbed. This step can effectively separate valuable metal materials from discarded electrode materials, providing a basis for subsequent recycling.

Fine grinding: Use a grinder to further finely grind the remaining pieces. Such fine powder treatment helps to increase the surface area and activity of the material, providing better conditions for subsequent material classification and recycling.

Air flow classification: Using air flow classification technology, fine separation is performed based on the difference in specific gravity of different materials. By controlling the speed and direction of the air flow, electrode materials of different particle sizes and densities can be separated, allowing for more precise extraction.

Electrode material recovery: In this step, the electrode material is subjected to offline powder processing and chemical extraction to strip away the metallic material. Through chemical treatment, useful metal components can be effectively separated, enabling efficient recycling and reuse of electrode materials.

The system uses automated production lines to accurately classify and extract electrode materials, with an average recovery rate of more than 90%. This not only provides important support for the circular economy of electric vehicles, but also realizes the resource utilization of hazardous waste and has a positive impact on environmental protection. With the continuous development of science and technology, related lithium battery recycling technology and equipment are also constantly updated and iterated, providing a more scientific and effective processing method for the recycling of lithium batteries. If you are interested in lithium battery recycling or have related needs, please feel free to contact us for consultation, and we will serve you wholeheartedly. Through our professional systems, lithium-ion battery recycling will be more efficient and environmentally friendly, contributing to building a sustainable future.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231