Application and working principle of Cable Wire Recycling Machine

Copper has good electrical conductivity and is widely used in the manufacture of wires, cables, brushes, etc .; a large number of waste wires are also produced every year. If it can be properly handled and the waste wires are converted into copper, then its recycling value is also very objective. Here, a special equipment is needed to separate the copper --- Cable Wire Recycling Machine.

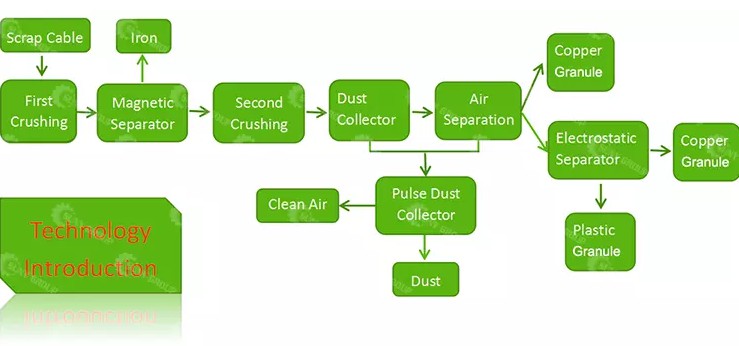

The Cable Wire Recycling Machine is a machine for crushing waste copper wires to separate copper from plastic. Because the separated copper is like rice grains. So called Cable Wire Recycling Machine. Cable Wire Recycling Machine is a kind of environmental protection machinery. The Cable Wire Recycling Machine mainly separates waste wires and cables from metal and plastic. After environmental protection measures, the waste wires and cables are treated without pollution, completely eliminating the severe environmental pollution problems caused by the separation and recycling of old waste wires and cables.

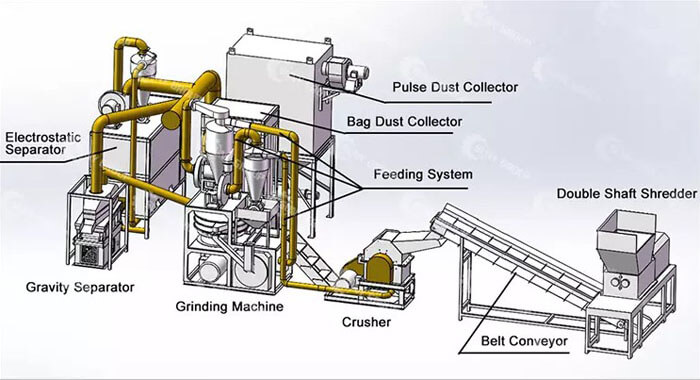

The Cable Wire Recycling Machine is a new type of recycling equipment for renewable resources, which effectively addresses the current crisis of scarce resources. Tongmi machine equipment is not suitable for various automotive circuit lines, motorcycle lines, battery car lines, and various household appliance lines such as televisions, washing machines, refrigerators, air conditioners, as well as various wire strippers such as communication lines and computer lines. Processing of various waste lines. The overall structure of the equipment is compact, the layout is reasonable and does not occupy land, and the operation is simple and convenient. Just plug in the power and you can directly enter the production. The equipment is equipped with a full-automatic crusher, feeding, crushing, vacuuming, and separation. The whole process requires only one person to feed, and the production process can be completed. The equipment has high-quality dust collection equipment. After dry sorting, the separated finished product can be directly entered into the market for sale.

With the development of science and technology, the industry's demand for processing and recycling copper wires is also increasing. In recent years, the structure and style of Cable Wire Recycling Machines have also developed rapidly. Although each manufacturer's Cable Wire Recycling Machine has its own structure and style. But in general, Cable Wire Recycling Machines can be divided into: 1. Dry type Cable Wire Recycling Machines. 2. Wet type Cable Wire Recycling Machine.

Dry type Cable Wire Recycling Machine

The so-called dry Cable Wire Recycling Machine refers to the Cable Wire Recycling Machine in the sorting method without adding water during the sorting process. This type of Cable Wire Recycling Machine mainly uses airflow sorting machines, or more environmentally friendly methods such as air shakers or electrostatic sorting to sort. The main process is: crushing-air separation-(static separation)-dust collection. (Electrostatic sorting is rarely used on current Cable Wire Recycling Machines.)

Wet type Cable Wire Recycling Machine

Wet sorting is a more traditional method. The idea of this sorting method mainly comes from beneficiation. The wet type is mainly used for gravity shaker sorting. The main process is: crushing and (add water)-gravity shaker (add water), because water is used in the production process, this method generally causes a small amount of secondary pollution to the environment, but it can effectively Recycling of miscellaneous wires, plug wires and wool wires, etc., has a wide range of applications.

Scope and function of the integrated combined dry powder copper wire machine: The dry powder copper wire machine is specialized in processing all kinds of cables and strippers below Φ20mm, such as automobile cables, communication cables, etc. Wire and cable. After crushing, shaker screen is separated, vibration is separated, and washed with water. It can completely separate copper and plastic, and achieve the purpose of comprehensive utilization, which has high economic benefits. And no dust and no secondary pollution. In addition, the device has an integral combined structure, which is convenient for installation and commissioning, and convenient to transport. After the customer purchases it, it can be produced by plugging in the power and stable performance.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231