Automatic Components Dismantling Machine

- Product Introduction:

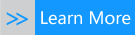

Automatic Components Dismantling Machine is used to remove the electrical components from the waste PCB.Because the components are with different precious metals and some parts can be sell separately and directly with a better price.And the mother boards after remove the components are easily to crush and separate the copper.

Video Description:

Product Description:

Automatic Components Dismantling Machine is used to remove the electrical components from the waste PCB.Because the components are with different precious metals and some parts can be sell separately and directly with a better price.And the mother boards after remove the components are easily to crush and separate the copper. It reduces the work of the next step,and make the precious metals can be recovered more.

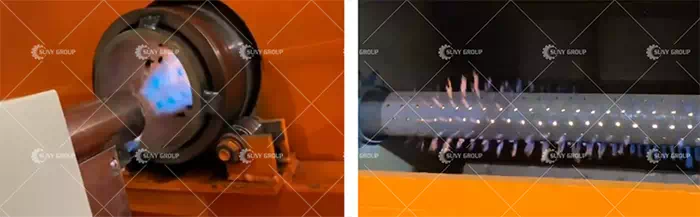

Working Principle:

Use the nature gas as the heat, the tin will loose when the temperature arrive at 200-300C. These electronic components will be separated because of scraping function between the circuit board when the rotary drum works.

So we can dismantle electronic components from PCB mother board. If our customer want to classify them clearly, then we can equipped with electronic components screen and magnetic machine.

Electronic component screen: Classify the similar size electronic components in one side;

Magnetic separator: Further classify these components which include iron or not.

Main characteristics:

1. Full automatic working, save labor, two persons are enough.

2. Tin remove and dismantling components at one step.

3. Automatic temperature controlled by our heating system.

4. Large capacity: 200kg/h,300kg/h,500kg/h.

5. Operating safety and easily.

6. Less damage to the components,keep the precious metals no losing.

7. Mother board and components can be proceed respectively in the next step to improve economic benefits.

8. Friendly to the air environment,all the smoke processing by the waste gas treatment system.

Technical parameters:

Model Power(kw) Weight (kg) Capacity(kg/h) Dimension(m) ZCJ-200 0.75+1.1+3 350+100 200 1.67*0.97*1.4 ZCJ-300 0.75+2.2+3 500+200 300 1.85*1.2*1.52 ZCJ-500 0.75+3+3 800+300 500 2.1*1.27*1.74 Customer Case:

Test and inspection:

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.

RELATED MACHINERY:

PCB Circuit Board Recycling Line

-

Product Introduction:

This circuit board recycling equipment adopts the world's advanced physical crushing technology, equipped with secondary crushing and high-voltage electrostatic sorting system to realize efficient recycling.

E Waste Recycling Plant

-

Product Introduction:

Suny Group's e-waste recycling plants turn electronic waste into treasure. This process protects the environment, recycles resources, and creates significant profit.

-

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231