Lithium Battery Recycling Plant

- Product Introduction:

Advanced Lithium Battery Recycling Machine with nitrogen protection for zero-risk shredding. Efficiently separates high-purity black mass, copper, and aluminum for your complete recycling plant solution.

Video Description:

PRODUCT DESCRIPTION:

Responding to the global demand for critical battery metals, we introduce a new generation of Lithium Battery Recycling Machine. This system is dedicated to providing the safest and most efficient processing solution for spent lithium batteries. Our integrated Lithium Battery Recycling Machine combines advanced thermal treatment and dry mechanical separation technology, ensuring that key resources like black mass, copper, and aluminum are recovered at exceptional purity, generating sustainable economic value for your plant project.

RAW MATERIALS:

Over the years, we have been engaged in the research, development, and production of lithium-ion battery recycling plant. We have tested over a hundred types of lithium-ion battery recycling and our technology has been continuously improving. Our aim is to provide our customers with more professional and reliable recycling machine.

At present The lithium battery recycling machine is used for dismantling andrecycling the Soft pack-age battery, cellphone battery, Shell battery,Cylindrical battery etc. Different types of lithium bat-teries have different recycling procedures. Please contact us for detailed configuration.

TECHNOLOGY INTRODUCTION:

This Lithium Battery Recycling Machine is composed of a series of customized, high-performance modules that ensure the continuous operation and high recovery rate of the production line.

1.The process begins with the Feeding Belt, which conveys the discharged battery. The material then proceeds to the Single Shaft Shredder, which processes the battery into 2-3cm pieces under nitrogen protection, achieving the preliminary separation of shells, anode sheet, cathode sheet, and diaphragm film.

2.Next, the material is transferred to the Pyrolysis furnace, which functions to evaporate the electrolyte, roast the material, and remove the film. The electrolyte gas is sent to the Electrolyte second burning chamber and subsequently treated by the Tail Gas Processing System (Scrubber + Active Carbon + Catalytic combustion system) to ensure environmental compliance.

3.Following the thermal process, the material enters the Zigzag Airflow Separator, which separates the shell (including iron, plastic, aluminum shells) and light material from the heavy material (anode/cathode pieces). The Magnetic Separator then recovers the steel shell (iron shell) from the mixture of shells.

4.The heavy material moves to the Rotary Drum Screen to screen out black mass. Material above the screen is conveyed to the Crusher with Noise Proof Room, which breaks the anode and cathode metal pieces and knocks down the black mass.

5.The black mass from the crusher output is again screened by the Rotary Drum Screen. The copper and aluminum granules (from the top of the screen) are then conveyed to the Grinder, which refines the particles to release more black mass.

6.Finally, the floating black mass is collected by the Cyclone Collector. The material from the Grinder passes through the Liner vibration screen to screen out the black mass. The final metal granules are separated by the Airflow separation separator, which specifically collects copper and aluminum.

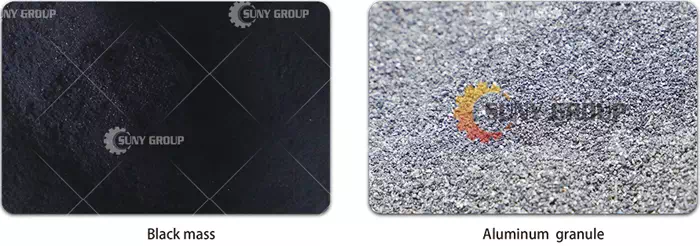

FINAL PRODUCTS:

The final products are black mass, aluminum granule, copper granule, plastic, steel shell and separator plastic etc. The output will vary depending on the type of battery.

CORE ADVANTAGES:

1.Zero Fire Risk: Safe Shredder under Nitrogen Protection

Safety is the paramount prerequisite for any Lithium Battery Recycling Solution. Our Lithium Battery Recycling Machine completely solves the industry's number one challenge: the fire risk from batteries with residual charge. In the core shredding stage, the system employs a Nitrogen Protection System to create an inert atmosphere, eliminating the possibility of explosion or ignition. This makes our equipment the most reliable Lithium Battery Recycling Machine on the market.

2.High-Value Output: High-Purity Black Mass and Metal Separation

This set of Lithium Battery Recycling Machines achieves industry-leading material purity through an optimized process. After thermal pyrolysis to remove binders, the mechanical dry separation process plays a crucial role: the core product, black mass (rich in cobalt, nickel, and manganese), is recovered at high concentration and purity; simultaneously, the separation efficiency for copper and aluminum is exceptional, High-purity recovered materials command a premium market price, ensuring a rapid return on your investment.

TECHNICAL STANDARDS:

Feature Item Indicator Requirments Recovery Rate of Metallic Aluminum 98% Powder Recovery Rate 98% Content of Powder In Metal Aluminum 2% Content of Metallic Aluminum In Powder 2% Other Contain dust collecter with not pollute Qualified Rate 99% Failure Rate 1% CMR ≥1.67 TECHNICAL PARAMETER:

Model Capacity LDC-300 200-300kg/H LDC-500 500kg/H LDC-800 800kg/H LDC-1000 1T/H LDC-1500 1.5T/H LDC-2000 2T/H Note:

1.Working voltage:380±10V(415V ,440V also can be custom);

2.The parameters and configurations above are for reference only. We can provide customized solutions and related lithium battery recycling machines based on different requirements. Please feel free to contact us anytime to discuss your specific needs.

CUSTOMER WORKSITE:

Provide Lifelong Technical Support

1. Provide field installation service to make sure the normal operation of the equipment.

2 Provide detailed technical training for customers. Including the equipment operation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

RELATED ARTICLES:

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231