Recycling production line of waste refrigerators

- Product Introduction:

When the waste refrigerator (or freezer) is on the unpowered drum, disassemble it manually and remove the plastic and glass from the box

Video Description:

PRODUCT DESCRIPTION:

RAW MATERIAL:

FINAL PRODUCTS:

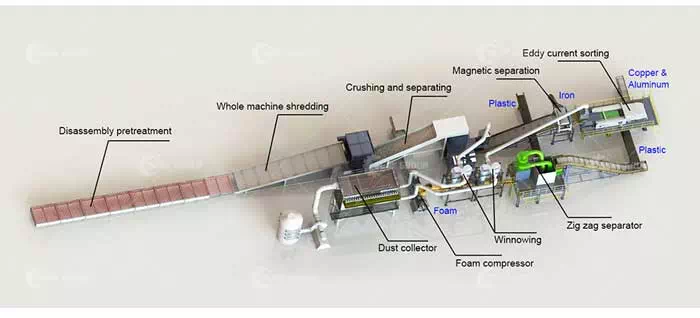

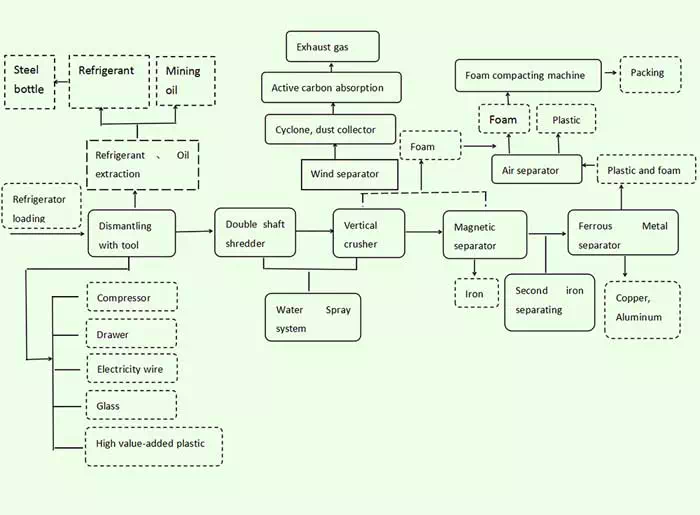

WORKFLOW:

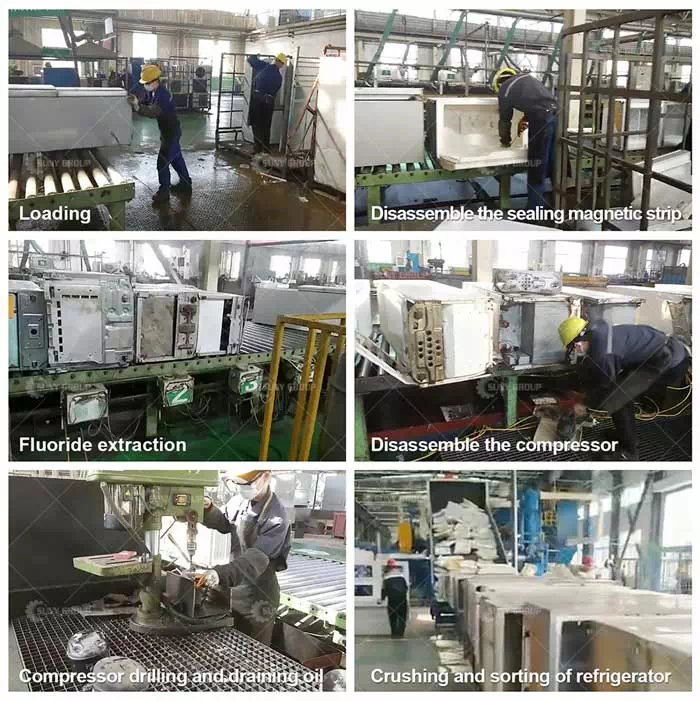

1. When the waste refrigerator (or freezer) is on the unpowered drum, disassemble it manually and remove the plastic and glass from the box;

2. According to different types of refrigerants, refrigerant recovery devices are used to classify and recover refrigerants. Remove the compressor and condenser, etc.

3. The whole machine enters a double-shaft shredder for shredding and preliminary crushing.

4. The materials enter the hammer crusher, and are crushed for the second time through crushing and kneading by the crusher.

5. At the same time of secondary crushing, part of polyurethane foam will be separated into foam separator by air separation. Heavy materials such as plastic and metal enter the belt conveyor.

6. Materials crushed by plastic and metal are separated by magnetic separation on the belt, and then enter eddy current separation.

7. Non-ferrous metals, such as copper and aluminum, are separated by eddy current, and plastic and foam materials are transported to the airflow separation system through belts to separate pure plastic and foam. Polyurethane foam is compressed into blocks by a foam crusher.

MAIN EQUPIMENTS:

TEATURE:

1.Negative prossure

The whole recovery process is a sealed negative pressure environment, which reduces the emission of gas and pollutants.

2.No polluton

The recovery production line is equipped with a dust removal system, and the gas and particulate matter are collected and treated by the dust removal system and discharged up to the standard.

3.Safely

Many parts of the production line are equipped with detection facilities such as temperature and cyclopentane gas concentration, and graded alarm and safety control are carried out.

4.Automation

The refrigerator production line is equipped with an intelligent automatic control system, which adopts man-machine isolation operation mode, monitors the system in real time through the monitoring screen, and keeps abreast of the equipment operation.

CUSTOMER SITE:

PARAMETER:

Capacity 600 units/hour (the production capacity is based on the processing of 120L-220L refrigerators, which can handle refrigerators with specifications above 220L) Equipment size 51000X13000X6500mm (Customizable) Capacity reduction ratio of polyurethane foam 1/5-1/8 lron recovery rate (weight%) ≥99% Recovery rate of copper and aluminum (weight %) ≥97% Plastic sorting rate (weight %) 97% (<3% foam in recycled plastic) The sorting rate of major materials shall be tested according to the enterprise standard of our company (Q/BAHI 001-2010) The emission of noise and particulate matter meets the requirements of relevant national standards (reference standards:

GB12348-2008,GB 16297-1996)

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231