Waste Plastic Granulating Recycling Machine

- Product Introduction:

Plastic granulator, also known as plastic pellet machine, plastic granulator, is a kind of mechanical device to cut plastic film, sheet, pipe, bottle, barrel, box and other waste plastic or plastic products into granules.

Video Description:

PRODUCT DESCRIPTION:

OUR PRODUCTION LINE IS CONFIGURABLE, PLEASE CONTACT US FOR DETAILED INFORMATION

01. PET bottle crushing cleaning and pelleting production line

02. PE/PP film woven bag cleaning and pelleting production line

03. PE/PP rigid plastics crushing cleaning and pelleting production line

04. PC,ABS electrical appliance plastics crushing cleaning and pelleting plant

RAW MATERIAL:

Some common materials for plastic pelletizer: PE film, PP pipe, PET bottle, PVC sheet, ABS waste, etc.

PROCESS FLOW:

Waste plastics → Cleaning & sorting → Drying pelleting → Finished Plastic Granules

FINAL PRODUCT

The final product of a plastic pelletizer is plastic pellets, also known as plastic granules. These pellets are small, cylindrical pieces of plastic that are typically 2-5 mm in diameter and 5-15 mm in length. They are made from a variety of plastic materials, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS).

EQUIPMENT DETAILS

SHREDDER:To shred and pretreat large pieces of plastic such as barrels or casings, and the output size is 30-80mm

Motor Power: 45KW

Output: 1500KG/H-2000KG/H

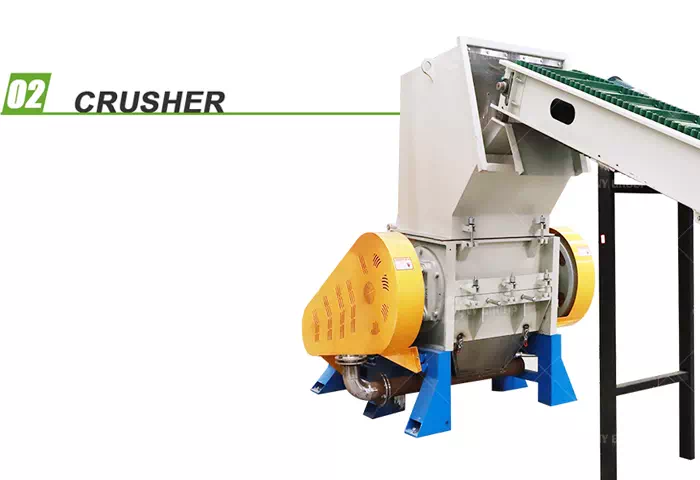

CRUSHER:The plastic is crushed by a crusher, The output is 2-3 cm pieces, for storage and further cleaning.

Motor Power:90KW

Output capacity:>1000kg/h

Configure different types of crushers according to the production line, please contact me for details

WASHING:transportation, cleaning

Spindle diameter: medium 500mm

Effective length:4000mm

Motor power:30KW

Blade thickness:6mm

Rotor speed: 750rpm

Mesh thickness:3mm

The parts in contact with the material are stainless steel

RINSING MACHINE:Separation of sand/slurry or small powders from flakes

Motor: 22KW

Material: The parts in contact with the material are stainless steel

Blade thickness:10mm

Sieve hole: 3mm

Spindle diameter:550mm

Spindle speed: 1200rpm

DEHYDRATOR: used to reduce water content

Motor power: 30KW

Rotation diameter:500mm

Length:1600mm

Speed: 1500 rpm

Bearing: NSK

Dehydration rate: 98%.

The parts in contact with the wet sheet are made of SUS304

PELLETING MACHINE: plasticized to reach the melting point, extruded and pelletized

Power: 75-250KW

Screw speed 10-150rpm

Filtration method:mesh plate/non-mesh grinding head

Pelletizing: Water Ring Pelletizing/ Strand Pelletizing

TECHNICAL PARAMETER

PET bottle crushing cleaning and pelleting production line

Model Power Capacity PET500 150kw 500kg/h PET1000 220kw 1000kg/h PET2000 260kw 2000kg/h PE/PP film woven bag cleaning and pelleting production line

Model Power Capacity PP500 140-225kw 500kg/h PP1000 270-320kw 1000kg/h PET2000 260kw 2000kg/h

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231