Waste Radiator Recycling Equipment

- Product Introduction:

Waste Radiator Recycling Equipment handles large radiators and ≤15cm motor rotors. It crushes materials into 3cm pieces, separates iron with a magnet, and sorts copper, aluminum, and plastic by airflow.

Video Description:

Product Description:

Raw Materials:

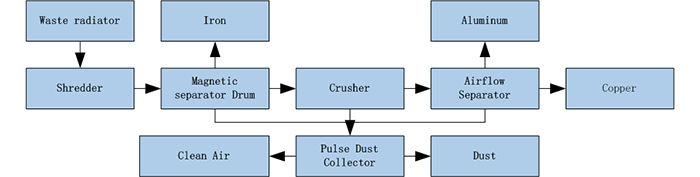

System Process:

The material be shreddered and then crushed into 3cm particles. Through the magnetic separator, iron is separated. Then the airflow separator can sort the copper, aluminum, plastic. The equipment has features of new design, nice appearance, unique and large capacity. Whole plant PLC controlling, one time feeding, multi machine cooperated processing; with automatic shutdown device and the overload automatic alarm device. Successful development of the processing line, greatly liberate the productive forces, improve the metal recycling quality. The most important, it solves the problem of dust overflow effectively, reducing the pollution to air.

Production Process:

Final products:

Main characteristics:

1. The entire production line adopt PLC control, ensuring the equipment operation stability.

2. Simple structure, reasonable layout; large processing capacity, stable operation; durable, safe and reliable

3. The shredder adopts two axes of the double roller design, with advantages of low noise, large torque, and large crushing chamber etc.

4. The shredder’s cutter adopts tool steel, made by a special processing technology, wide application ranges. it combines cracking, tearing, and extrusion crushing, It applies to shredder different raw materials easily.

5. Magnetic separation equipment adopts strong magnetic drum separator, with sorting rate of 99%.

6. Pulse dust removal system inhibits the dust overflow in 99% efficiency, in full compliance with national environmental requirements "air pollutant discharge standards" GB16297-1996, no secondary pollution.

7. Using airflow sorting machine, with sorting rate of 97%

Technical parameters:

Model Capacity(Kg/H) Sorting Efficiency Dust Removing Efficienty Power(Kw) SRP-1000 1000 97% 99% 55*2 SRP-2000 2000 97% 99% 75*2 SRP-3000 3000 97% 99% 115*2 SRP-5000 5000 97% 99% 145*2 Customer Case:

Test and inspection:

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.

RELATED MACHINERY:

Aluminum Copper Waste Radiator Cutting Separating Machine

Low Price Aluminum Copper Radiator Cutting and Separating Machine from China is ideal for single and double-layer copper tube radiators. It efficiently processes radiators in 19mm, 21mm, and 25mm sizes.

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231