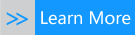

Jelly Cable Recycling Line

- Product Introduction:

The jelly cable recycling line uses a combination of processes including crushing, screening magnetic separation, flotation, fine crushing and shaking table sorting to achieve efficient recovery of copper and plastic, and is suitable for processing jelly cables of various specifications.

Video Description:

PRODUCT DESCRIPTION:

The jelly cable recycling line uses a combined process of primary crushing, vibrating screen with magnetic separation, flotation separation, fine crushing, and shaking table density separation. This ensures high recovery of copper and plastic sheaths with minimal loss. The system is highly automated, reducing labor costs, and adopts water recycling technology to achieve eco-friendly and low-emission operation. Flexible in design, it can efficiently process different sizes of jelly cables, making it an ideal solution for sustainable cable recycling.

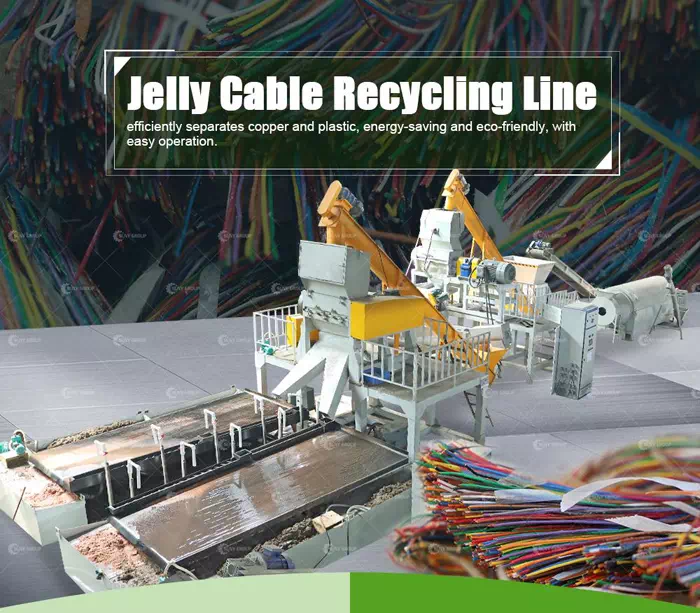

EQUIPMENT STRUCTURE:

The jelly cable recycling line adopts a combination process of primary crushing + vibrating screen & magnetic separation + flotation separation + fine crushing + shaking table density separation, achieving efficient recovery of copper and plastic sheaths. High automation, reducing labor costs. Environmentally friendly, with water recycling and low emissions. Flexible equipment, capable of handling different cable sizes.

PROCESS AND ADVANTAGES:

1.At the beginning of the line, a wire separator is used to perform primary crushing of waste jelly cables. The crushed material size is approximately 2-3 cm, suitable for subsequent separation and crushing.

2. Material passes through a vibrating screen for particle size classification, and then through a magnetic separator to remove ferrous impurities.

3. Crushed cables enter the flotation tank, where water flotation separates the plastic sheath. Some sheaths that were already broken in primary crushing can also be effectively separated.

4. The cables, after plastic separation, are conveyed via screw conveyor to a knife crusher, further crushing the remaining material into approximately 2mm particles.

5. The crushed material enters the shaking table, where density differences are used to separate copper and plastic sheaths, producing high-purity copper and clean plastic particles.

6. The separated copper granules enter the dehydrator to remove moisture, then are placed into the dryer. Dryer has high-efficiency hot air drying for clean and uniform copper granules.

7.The equipment is equipped with a centralized PLC control system, enabling intelligent and automated management of the entire production line.The user-friendly interface allows flexible parameter adjustment, ensuring efficient and stable operation.

8. 99% High-purity: High-precision separation, with copper purity up to 99% or higher.

RELATED MACHINERY:

Cable Wire Recycling Machine

The cable wire recycling machine is used to separate and recover copper particles and PVC particles from various waste copper wires and cables. It is efficient and stable, and the purity can reach more than 99%.

Mini Copper Wire Granulator Recycling Machine

A mini copper wire granulator is a compact machine used for recycling and processing copper wires. It is designed to separate copper from the plastic insulation that surrounds it, allowing for more efficient recycling of copper materials.

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231