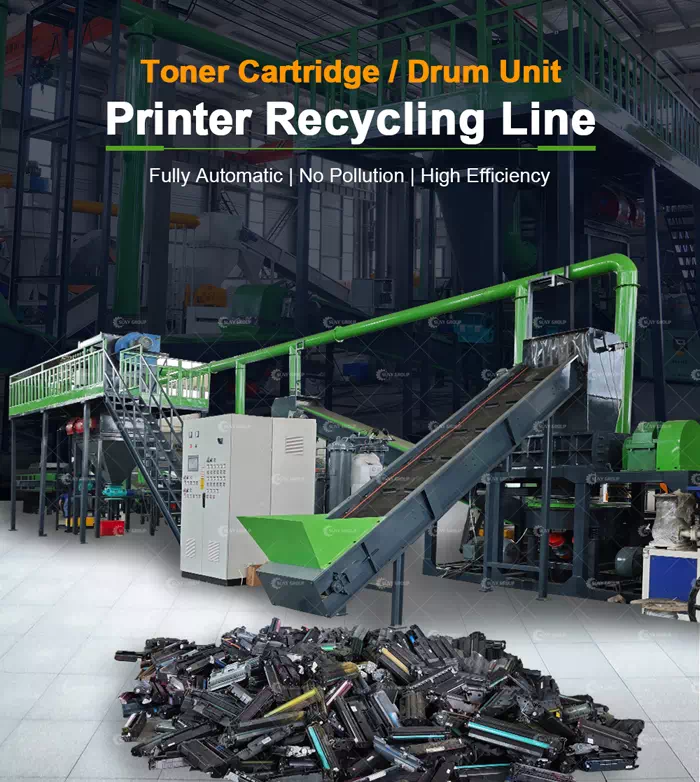

Printer Drum Unit Recycling Line

- Product Introduction:

This fully automated printer toner and photosensitive drum recycling line is specifically designed for used toner cartridges and drum assemblies. Through efficient mechanical crushing and sorting processes, the equipment precisely separates and recycles plastics, copper, aluminum, non-ferrous metals, iron, and other resources, achieving pollution-free processing and resource reuse.

Video Description:

PRODUCT DESCRIPTION:

This fully automated printer toner and photosensitive drum recycling line is specifically designed for used toner cartridges and drum assemblies. Through efficient mechanical crushing and sorting processes, the equipment precisely separates and recycles plastics, copper, aluminum, non-ferrous metals, iron, and other resources, achieving pollution-free processing and resource reuse. The system boasts a high degree of automation, stable operation, and significantly improved recycling efficiency, making it an ideal solution for green environmental protection and the circular economy.

RAW MATERIALS:

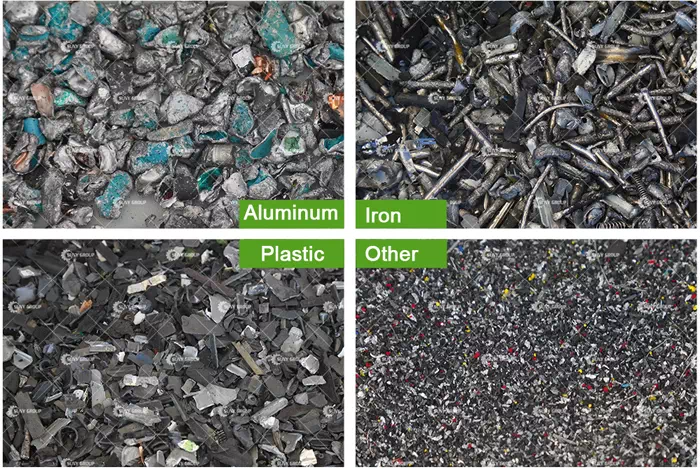

FINAL MATERIALS:

WORKING PROCESS:

1. Material Feeding: The raw materials are loaded onto a chain-type conveyor, which transports them steadily into the shredder.

2. Primary Shredding: The shredder breaks the materials into large pieces, making them suitable for further processing.

3. Secondary Crushing: The shredded materials are then transferred via conveyor to a hammer crusher, where they are crushed into smaller, uniform particles.

4. Dust Collection: A dust collection system operates simultaneously to capture dust generated during the crushing process, ensuring a clean and environmentally friendly operation.

5. Magnetic Separation: The crushed material passes through a magnetic separator, which removes ferrous metals (iron) from the material stream.

6. Eddy Current Separation: Each of the three size-based outputs is fed into a dedicated eddy current separator, which effectively separates non-ferrous metals (like aluminum and copper) from plastic.

PRODUCT STRUCTURE:

Double-Shaft Shredder: The material is first pre-shredded by a double-shaft shredder, reducing size and improving processing capacity.

Hammer Crusher- Secondary Crushing: The crusher further reduces material size to 2-3 cm for efficient separation. The entire crushing and conveying process is fully enclosed, preventing dust leakage and ensuring a clean working environment.

Material Classification & Iron Recovery: The vibrating screen classifies the material; fine residues are screened out while larger particles move to the next stage.Magnetic separation removes ferrous metals such as iron effectively. The ecycling line uses Schneider components and PLC control.

Eddy Current Separator: After magnetic separation removes iron, the materials enter the eddy current separator, where copper, aluminum, and plastics are efficiently recovered,achieving a separation efficiency of over 98%.

Environmental Design & Safety Assurance: The entire recycling process is equipped with a nitrogen protection system, creating an inert atmosphere during material shredding and separation to prevent toner or metal dust from contacting air, thereby reducing fire and explosion risks and ensuring operator and equipment safety. In addition, the pulse dust collection system efficiently captures dust and toner, making the entire recycling line safe, environmentally friendly, and clean.

MANUFACTURING & PRODUCTION:

To ensure the machine performance, for every machine before leave our factory no matter its single machine or big production line, we all connecting whole line, buy raw materials to trial running, to ensure every part are up to standard.

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231