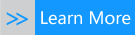

Wind Turbine Blades Recycling Line

- Product Introduction:

The recycling of wind turbine blades involves reusing or regenerating the materials from discarded blades through the recycling process.

Video Description:

RECYCLING STATUS:

The recycling of wind turbine blades faces significant challenges, mainly due to the materials used, such as glass fiber and carbon fiber reinforced polymers, which are difficult to process.

To address this issue, SunyGroup has developed a blade recycling production line that effectively separates and recycles the glass fiber, resin, balsa wood, and other materials found in wind turbine blades

RECYCLING VALUE:

After utilizing wind turbines for power generation, the discarded turbine blades should also be properly recycled and reused. Since wind turbine blades are typically made from composite materials like glass fiber and carbon fiber reinforced polymers, these materials do not degrade easily. Therefore, proper disposal and recycling are crucial for environmental protection.

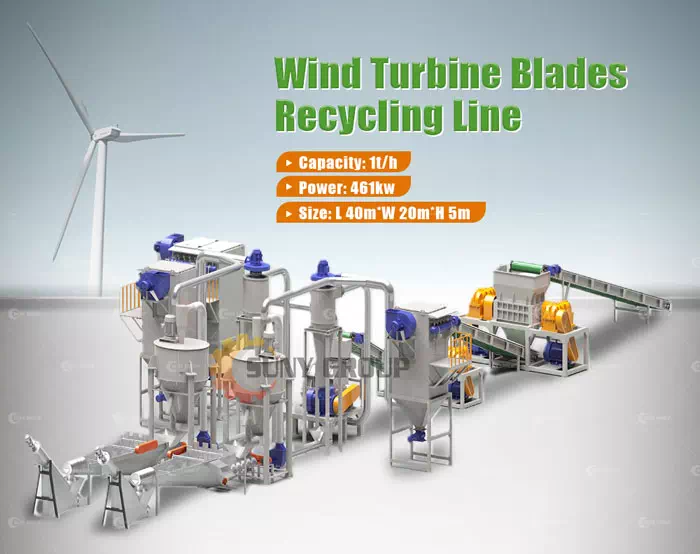

1. Glass Fiber Reinforced Composites

Glass fibers and polymer resins, typically epoxy or polyester resins.

2.Carbon Fiber Reinforced Composites

Carbon fibers and high-performance resins, such as epoxy resin.

3.Wood/Foam Core Materials

The inner core of the blade may use lightweight wood or foam, with composite materials on the outer layer.

Through our company recycling techniques, materials such as resin, glass fibers, and others can be separated and reused, minimizing resource waste and reducing environmental impact.

The final products include resin powder, small-sized fiber bundle, large-sized fiber bundles,and balsa wood. This recycling process effectively separates the various materials within the blades, enhancing recycling efficiency.

Recycling wind turbine blades not only helps in reducing waste but also allows the recovered materials to be repurposed in industries like construction and composite manufacturing, promoting resource circularity and supporting sustainability goals.

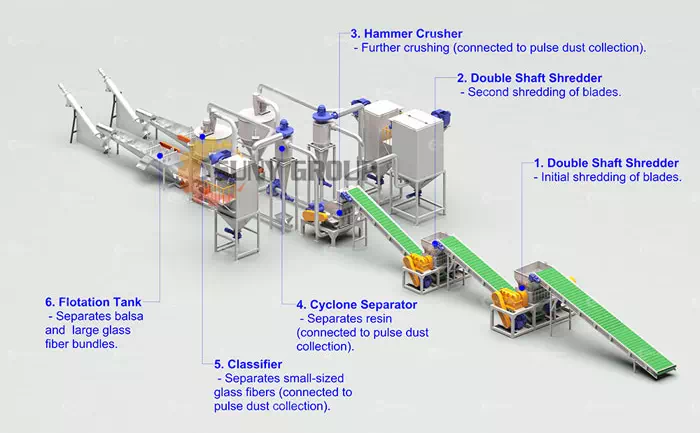

EQUIPMENT STRUCTURE:

Schematic diagram of the physical recycling line for Wind Turbine Blades crushing and sorting.

* All rights reserved. Please do not use it illegally.

MACHINE DETAILS:

Double shaft Shredder:The process of coarse crushing requires a double-shaft shredder to shred the material.

1000Hammer Crusher:The hammer crusher can further break down wind turbine blades, with a screen used to control the size of the output, making it easier for the next step in the separation process.

Three-stage sorting: 95% Sorting Rate. After the wind turbine blades are cut, they enter the recycling production line, where the materials undergo three stages of crushing and three different separation processes.The final products include resin powder, small-sized fiber bundle, large-sized fiber bundles, and balsa wood.

Pulse Dust Collector: The production line is equipped with 2 pulse dust collectors, which have high dust removal efficiency and can capture dust particles larger than 0.3 micrometers with an efficiency of up to 99%.

Utilizing PLC control: Continuous feeding, intelligent operation,automatic alarms, bilingual interface, easy and efficient operation, ensuring stable equipment operation.

TECHNICAL PARAMETER:

Model Capacity Power Size ZYW800 1t/h 461kw 40m*20m*5m

RELATED MACHINERY:

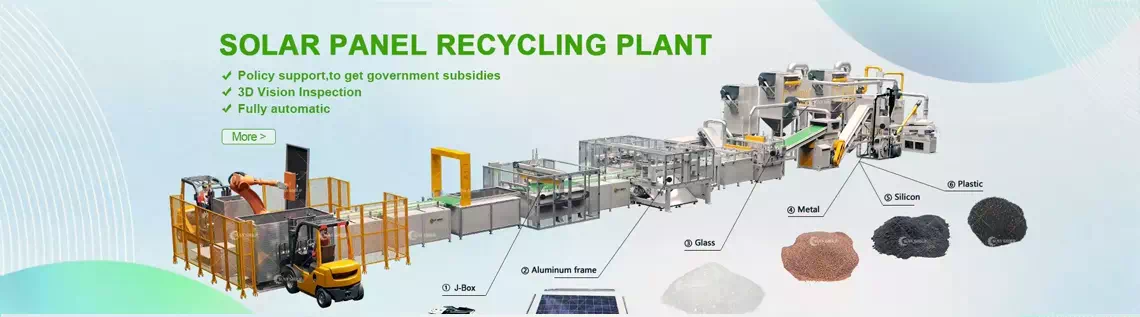

Solar Panel Recycling Plant

Solar PV panel recycling machines recover valuable materials like copper, silver, silicon, plastic, and glass from components such as aluminum frames, glass, EVA, solar cells, back sheets, and junction boxes for reuse in production.

Lithium Battery Recycling Plant

The lithium battery recycling plant is used for dismantling and recycling the Soft package battery, cellphone battery, Shell batter Cylindrical battery etc.

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231