Paper Plastic Separator Machine

- Product Introduction:

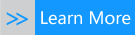

Paper Plastic Separator recycling production line is a set of production and processing equipment group specially developed by our company to solve the problem of scrap disposal in paper mill.

It can separate the plastic or aluminum in the waste paper from the paper, and recycle it to the maximum extent.

Video Description:

PRODUCT DESCRIPTION:

Paper Plastic Separator recycling production line is a set of production and processing equipment group specially developed by our company to solve the problem of scrap disposal in paper mill.

It can separate the plastic or aluminum in the waste paper from the paper, and recycle it to the maximum extent.

SUITABLE RAW MATERIALS

WORKING FLOW:

FINAL PRODUCT:

Function paper mill Laminated paper, bulk paper, kraft card board, trimmed edge, sanitary napkin diaper Paper-plastic Composite Woven Bag Main motor power KW 110KW 75KW-132Kw 55KW Rated speed r/min 380-560 380-560 380-560 Sieve diameter mm

Can be customized on request8 8 8 Screen thickness mm

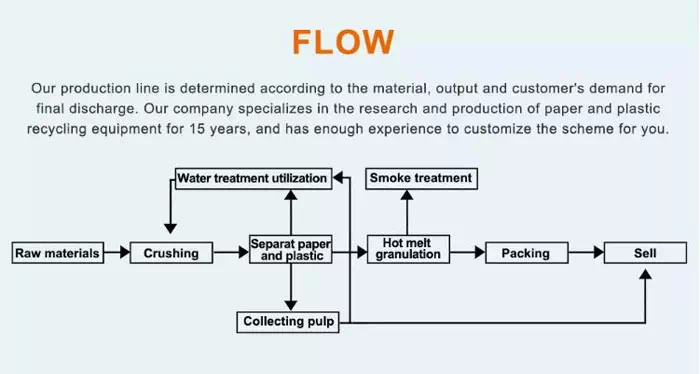

Can be customized on request8 8 8 Outlet (LxW) mm 800*800 800*800 800*800 Outlet diameter mm 220*2 220*2 220*2 Raw material handling capacity 150-200t/24h 1.5-3.5t/h 11000-11500条/h Footprint: width x length (mm) 1800*8000 1800*8000 1800*8000 Overall height mm 3300 3300 3300 Outlet height mm 1100 1100 1100 Pulp outlet height mm 800 800 800 PULP FILTER:

ln the pulping of waste paper, because of the different paper quality of waste paper, there is a large amount of slag.This machine can remove light and heavy sundries and decompose small pieces of paperin fibers, without blocking the sieve plate, and hard sundries will not hurt the sieve plate.The factory doesnot have to stop running for cleaning frequently, and it can also be used as a second pulping machine.lt is mainly used for sorting tail pulp after fiber separator and pressure screen; The treated and sortedslurry is directly returned to the fiber separator or the slurry pool in front of the pressure screen for reuse.After sortingThe tailings do not contain fiber, which meets the emission requirements of environmentalprotection.

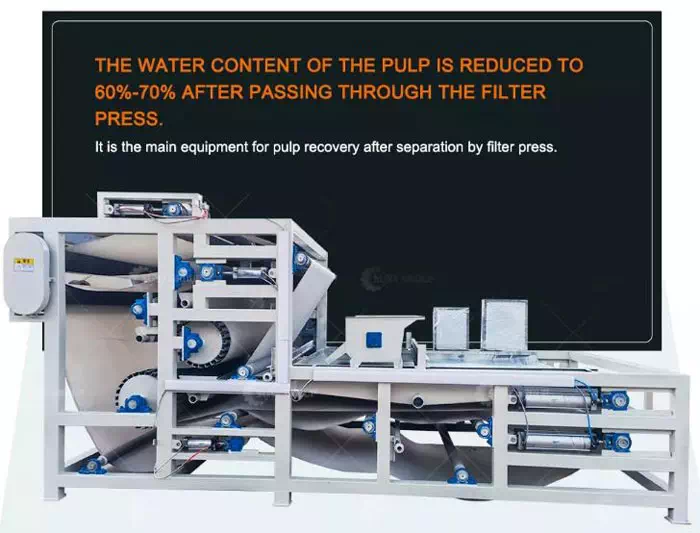

Model 380 450 500 Sieve length L1250*W610mm*2pcs L1500*W715mm*2pcs L1500*W795*3pcs Motor 45kw-4 75kw-6 90kw-6 Total length of equipment 3750mm 4150mm 5850mm Device width 780mm 850mm 925mm Base length 3000mm 3500mm 5160mm Pulp inlet 219 219 273 PULPDEHYDRATOR:

The basic working principle of the pulp dehydator is: the particles rotate to a certain height with the drum,are thrown and fall by gravity, and are filtered through the screen to form a sieve. The roller screen is shaftdriven, and the screen is steel wire woven net or high toughness nylon woven net. The ruler of the sieveholes can be configured according to the technological requirements.

Model Motor power Kw Screen Density Screen length mm Weight kg Output kg TS-200 0.75 100 2000 150 500 TS-300 1.5 100 3000 200 750 TS-400 2.2 100 4000 270 1000 TS-500 2.2 100 5000 350 1300 PULP FILTER PRESS:

Pulp filter press is a mechanical equipment designed for the recycling of pulp separated by paper-plasticseparator. The pulp filter press uses the motor to drive the spindle to run and drive the polyester blanket. The pulp istransported to the filter press by the pump and evenly flows onto the polyester blanket. After being drivenby the polyester blanket, it is squeezed between two layers of polyester blankets, and then squeezed andcompacted by multiple pressing rollers, thus making cardboard for secondary utilization. The filtered clearwater can be pumped by a water pump for recycling, thus reducing emissions and saving resources.

Model 1500 2000 2500 Drive motor power KW 4 4 5.5 Polyester Blanket Specifications 1500x11300 2000x11300 2500x11300 2500x12700 1500x12700 2000x12700 Pulp processing capacity t/d 35-55 42-62 50-70 Covers an area of meters 2400x6000 2900x6000 3400x6000 Spindle speed r/min 37-61.5 37-61.5 37-61.5 CUSTOMER SITE:

RELATED MACHINERY:

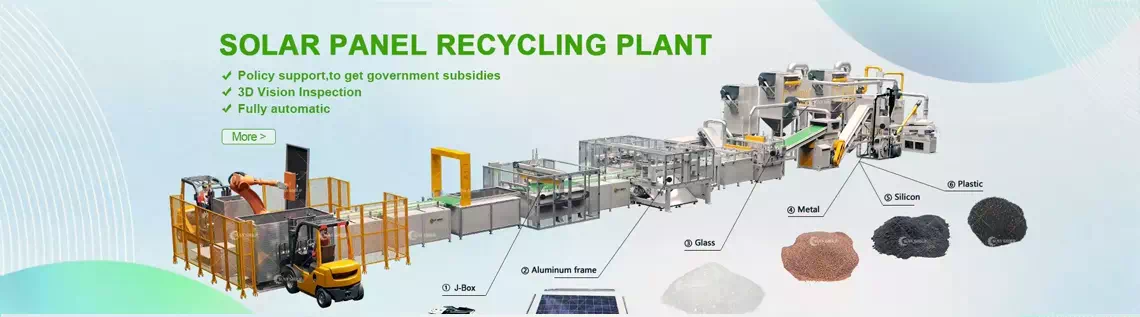

Aluminum Plastic Recycling Machine

Aluminum-Plastic Recycling Machine is used to separate aluminum and plastic from waste materials like aluminum tubes, bottle caps, car ornaments, and other aluminum-plastic products.

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231