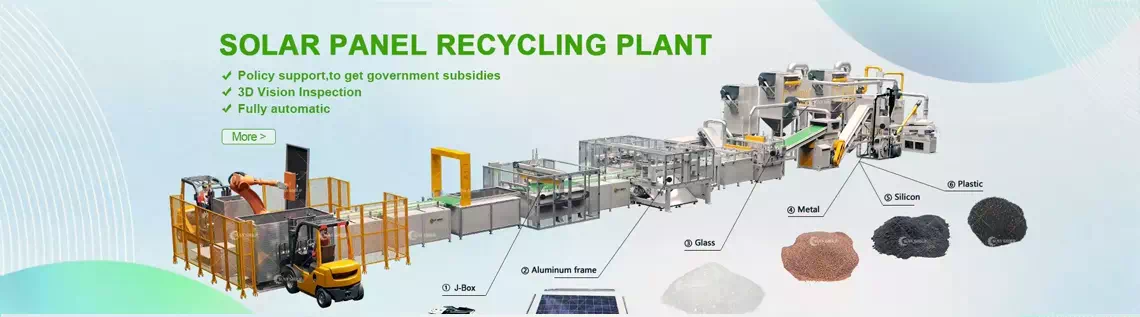

Automatic Tire Recycling Machine

- Product Introduction:

The resource of waste tires are mainly from waste tires, waste tire tubes, waste rubber belt, waste rubber hose, and waste rubber overshoes, then from the waste products and leftover bits generated while manufacturing rubber products. It belongs to one large categories of industry solid waste.

Video Description:

PROJECT DESCRIPTION:

Rubber powder and reclaimed rubber. This is a promising recycling way which integrates environmental protection and resource recycling, and is also a scientific, reasonable and wide used important way of disposing waste rubber. Rubber powder production has no secondary pollution and the use rate of waste tire is 100%. The rubber powder also can extend to high added value and recycled new type products, such as stadium runway, waterproof roll, modified asphalt, rubber floor tile, etc. The development of rubber powder industry is the direction of waste tire comprehensive utilization, and is also the industry strongly supported by many countries in the world.

PROCESS FLOW:

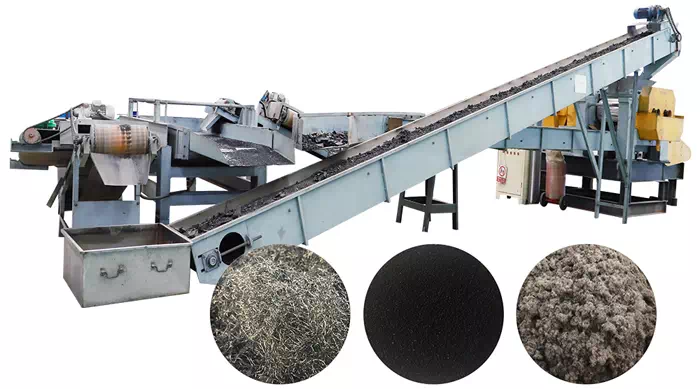

1.Steel wire drawing machine: pull out steel wire from tire bead

2.Tire shredder: crush whole tire into rubber blocks(3-8cm)

3.Steel wire separator: separate the rubber and steel wire and crush rubber blocks into rubber granules(10-15mm)

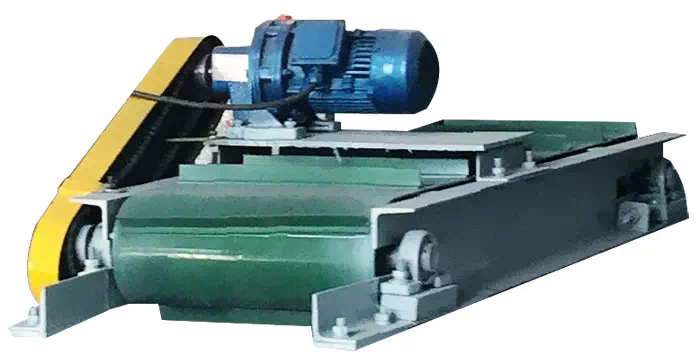

4.Magnetic separator: separate steel wire from the mixture of rubber granule and steel wire

5.Rubber granulator: crush rubber granules into more smaller size (0-4mm)

6.Magnetic separator: remove the residual tiny steel wire

7.Fiber separator: remove the nylon fiber and impurity.

Hydraulic Tire Cable Extractor

Use Structure And Principle

This machine consists of motor,hydraulic system,extracting hook,extracting mouth,main machine farme etc.The basic work principle is:the motor drives the hydraulic system and oil cyclinder,the hook is welded on the draw bar of the cylinder.the reciprocating movement of the oil pump and oil cylinder will cause the hook reciprocation.

Put the tire onto the hook mouth,extend the hook out of the mouth and hook onto the tire lip,the start the motor.Owing to the strong extracting force of the oil cylinder,the wire cable will be taken out as a whole ring.

Characteristics

If the buyer want to save the cost,he should choose this machine.Small power consumption,easy operation,convenient in movement.

Application

Take out the wire cable from the tire side

Disadvantage

It is manually operating machine,It would be a hard job for the worker whn he is dealing with a big tire,and the efficeient is low.

Model Power Oil cylinder maximum trip Adapt to the tire tension Reciprocating speed(Time/Min) Weight(kg) Size of oppearance 800 5.5Kw 800 800 5 1 600 2x0.5x1 1200 11Kw 1200 1200 15 1.5 1400 3x0.8x1 Whole Tire Crusher

Application

This machine adopts a Germany technology.It crushes a whole tire into the lumps at the size of 3~8cm directly,which will be ready for the shredding into the rubber powder at the size of 10~30 meshes and separating the wire pieces and fibers.

Characteristic

This machine possesses such features as compact structure,advanced technology,low energy onsumption,high efficiency etc.The crushing room adopts split structure,which is veryconvenient to maintenance.The machine adopts hard alloy steel as its blade,high rigidity and wearable.It could be re-used by sharpening for extending the service lifetime.

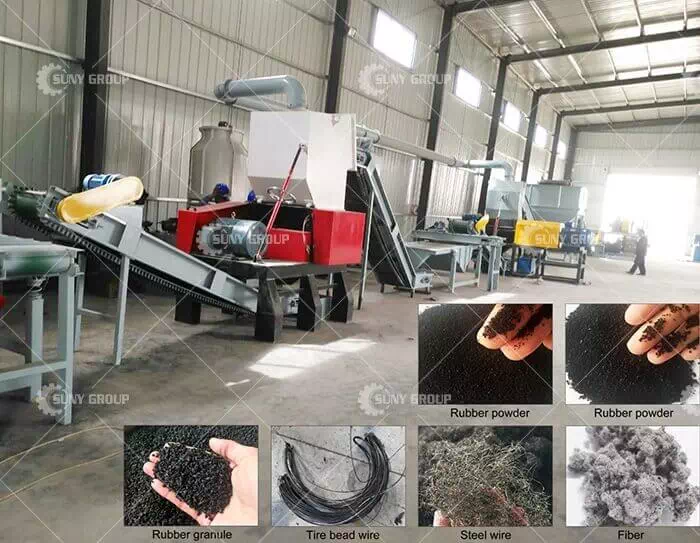

Size of input material(mm) Diameter800 whole tire Diameter1200 whole tire Size of output pieces(mm) 50x50 60x60 Shredding capacity 0.8~1.2 Tons/Hr 1.5~3 Tons/Hr Motor power(6 poles) 7.5+7.5Kw 15+15Kw Figure dimension(L×W×H) 3280x1870x2900mm 5200x2800x3500mm Total weight 5800Kg 15600Kg Magnetic Separator

It works by the theory of permanent magnetism rollers.It is widely used for separating the foreign metal matters from such materil of rubber powder,coal powder,construction material,glass material etc.It improves the material quality obviously by separation the mini metal powders.

Model ZY-CX30 ZY-CX40 ZY-CX30 Magnetic roller diameter 300mm 400mm 300mm Magnetic roller speed 0.648m/s 0.33m/s 0.648m/s efficiency 96% 96% 96% Motor power 0.55Kw 0.55Kw 0.55Kw Size of oppearance 800x920x710 920x1000x810 500x750x600 capacity 5m³/h 6.5m³/h 3m³/h Rubber Granulator

Rubber granulator is used to crush the rubber from the steel wire separator and the particle size can reach 1mm after crushing. Then they can reach the final size by particle sieving and circulation. Due to the particular design, the granulator can produce uniform and high quality rubber granule and above 99% of fiber is removed during production, so it has high separating efficiency.

Model Power(kw) Mesh size Dimensions Weight(kg) Capacity(kg/h) LD600 22kw Φ5.5 1100×1150×2000 1800 300kg/h LD800 45kw Φ5.5 1700×1600×2600 2500 600kg/h LD1000 75KW Φ5.5 2000×1800×2600 4500 800-1000kg/h LD1200 90KW Φ5.5 2150×2250×2950 5600 1000-1200Kg/h Rubber Powder Mill

Primarily pulverizing mill for crushing waste tires conducted at ambient temperature. Having a coarse pulverization, fine pulverization, and function of the isolated steel wire, etc.. The the material crushing effect of wire moles ideal. This machine adopts rotary milling works, material particles a performance of 10-30 mesh, screening, conveying pure colloidal particles can reach about 99% of the magnetic separator. Such as the need 40-100 purposes crumb, about 30 mesh particles directly ultrafine mill group processing.

Model Roll diameter*length Roll Rotate speed Quantity Power(kw) Overall size(m) Weight XKP-560 560*800mm 25.6r/min 1set 110 5320*2300*2000 21.3t Fiber Separator

It is a latest design of air separating equipment with good work performance.It is applied to separating the mini fiber piece from the rubber powder to improve its quality.It can alsobe applied to clarifying powder material in other Chemical industry.

Model 1100 type Capacity 200-500 Diameter of impeller 1100 Number of impeller(piece) 8 Rotate speed of main axis 400 Motor power 5.5 Dimension(LxWxH) 1.5x1.5x3.4 Weight(ton) 1.5 Feasibility Analysis Report

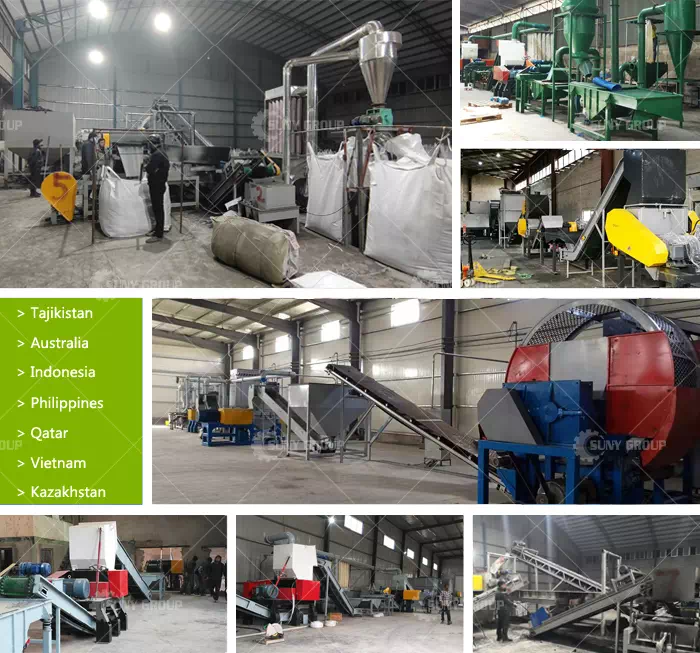

Model HNFA1000 HNFA15000 HNFA2000 Processing capacity 1000kg/h 1500kg/h 2000kg/h Raw material cost 1t/h*10h*300rmb =3000rmb 1.5t/h*10h*300rmb= 4500rmb 2t/h*10h*300rmb= 6000rmb Power consumption 240kwh*10h*1rmb / kwh=2400rmb 300kwh*10h*1rmb/kwh=3000rmb 450kwh*10h*1rmb/kwh=4500rmb Labor cost 90rmb/d*3workers=270rmb 90rmb/d*3workers=270rmb 90rmb/d*3workers=270rmb Total cost 3000+2400+270=5670rmb 4500+3000+270=7770rmb 6000+4500+270=10770rmb Rubber powder output and price 1t/h*10h*80% =8t*1300rmb/t=10400rmb 1.5t/h*10h*80% =12t*1300rmb/t=15600rmb 2t/h*10h*80% =16t*1300rmb/t=20800rmb Steel wire output and price 1t/h*10h*20%=2t*900rmb/t=1800rmb 1.5t/h*10h*20%=3t*900rmb/t=2700rmb 2t/h*10h*20%= 4t*900rmb/t=3600rmb Daily profit 10400-5670+1800=6530rmb 15600-7770+2700=10530rmb 20800-10770+3600=13630rmb Monthly profit 6530*30=195900rmb 10530*30= 315900rmb 13630*30= 408900rmb CUSTOMER CASE

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231