Waste Tyre Pyrolysis Plant

- Product Introduction:

Waste tire pyrolysis plant is one of the main ways of tire recycling at present. Waste tires go through a series of pyrolysis recycling processes in this equipment, and finally turn into gas, oil, carbon black and iron wire.

Video Description:

PRODUCT DESCRIPTION:

Waste tire pyrolysis plant is one of the main ways of tire recycling at present. Waste tires go through a series of pyrolysis recycling processes in this equipment, and finally turn into gas, oil, carbon black and iron wire.

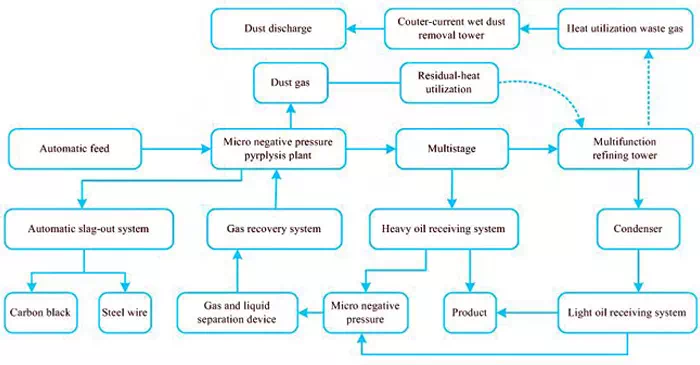

TECHNOLOGY PROCESS:

1. After pretreatment, the waste tires are transported into the pyrolysis furnace through the feeder. Different feeding devices can be selected for different materials, including screw feeder, hydraulic feeder, conveyor belt feeder, and manual feeding can also be used for special materials.

2. A large amount of pyrolysis oil and gas are produced during the pyrolysis process, and its components mainly include heavy oil (liquid state), light oil (gas state), pyrolysis gas and a small amount of water vapor, etc. The oil and gas flow into the gas distribution bag through the gas outlet pipeline. In the gas distribution bag, the heavy components condense to form heavy oil (sometimes called residual oil, the proportion of this part of oil varies according to different materials. The heavy oil sinks to the residual oil tank , stored in the oil storage tank through the oil pump. Light oil and gas components enter the cooling system through the air bag.

3. After the oil and gas are cooled by the condensing system, they will eventually be decomposed into a mixed liquid of light oil and a small amount of water and pyrolysis gas. The separated light oil is stored in the oil tank through the oil pump, and a small amount of oily wastewater is atomized and sprayed into the combustion chamber of the pyrolysis furnace for use as fuel;

After 8-10 hours of pyrolysis reaction, in addition to fuel oil and pyrolysis gas, carbon black and steel wire will also be generated in the pyrolysis furnace.

FINAL PRODUCT:

As a result of pyrolysis of waste tyres one obtains:

Oil(45% to 50%)

The main oil product produced by our recycling application is the fuel oil that is wide used for industrial and commercial purposes. The oil has 45% to 50% of the amount of recycled scrap tyres, which will be carried with licensed tanker trucks.

CARBON BLACK (30% to 35%)

Carbon Black is the main product recycled by Pyrolysis technology. The amount of recycled carbon black is 30% to 35% of the total amount of scrap tyres recycled in the system.

Carbon black produced by Pyrolysis process (CBp) is more economical compared to carbon black produced primarily from petroleum and is more price-efficient to be used as an ingredient in the industries listed;

STEEL WIRE (10% to 15%)

Tyres contain steel wires and the amount range of 10% to 15% of the total tyre wastage

GAS (5% to 8%)

Non-Condensable gases arise during the pyrolysis process.

FEATURE:

1. Inner of the pyrolysis line run in micro negative pressure, which can prevent gas leakage, so it is very safe. Also it is environment-friendly.

2. Horizontal and dual drive rotary structure, make equipment i heated evenly, and life is much longer.

3. Special process design can remove the corrosive gas effectively, reduce the equipment damage by corrosion and reduce the pollution.

4. The special stucture near the outlet of the reactor can prevent pipeline blocking, the whole equipment is more safe.

5. Innovative multiple-stage separator makes the oil yield higher and the quality of oil better.

6. Automatic feeding system and deslagging systm can help to save time and workers

7. New type counter-flow wet dust removal process can make the flue gas meet the environmental standard.

8. New self-cleaning condensing system solves te problem of condensing tube obstruction.

9. New design covers less area, higher oil yield, more safe and environmental.

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231