Technical manual of automatic one-to-two flat mask machine

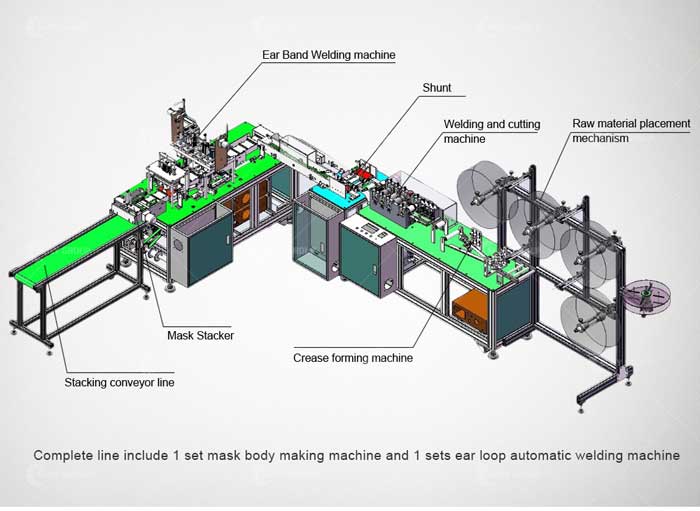

One-to-two automatic flat mask machine production line is a fully automatic high-speed flat ear-belt mask production line newly developed by SUNY GROUP. It includes automatic raw material feeding, automatic conveying, cutting off the nose bridge, mask edge welding, folding, ultrasonic fusion, forming, The whole process such as cutting is automated to complete the entire production process from the raw material of the coil to the finished mask.

The SUNY GROUP one-to-two fully automatic flat mask machine consists of one mask body machine and two ear belt machines. The automatic conveyor belt and connecting machine are added. The unique design helps companies improve production efficiency and reduce labor costs. The whole machine is automated from feeding, nose line insertion, edge sealing, and cutting of finished products. It only needs one person to operate, and the whole process is fully automated.

1. Suitable for the production of disposable flat masks.

2. Whether the masks produced by this production line are medical or not has nothing to do with the machine. As long as the masks are disinfected and analyzed, the masks produced by this production line can be used as surgical masks.

3. Masks of different sizes and styles can be produced by changing molds.

4. The plane mask production line adopts aluminum alloy structure, with good finish and no rust.

2. Machine function

1. Automatic delivery of raw materials

2. Automatic transportation of raw materials

3. Automatically cut off the bridge of the nose

4. Welding of the length of the mask

5. Folding

6. Edge welding in the width direction of the mask

7. Forming shear

8. Unloading

The SUNY GROUP one-to-two fully automatic flat mask machine production line realizes the fully automated production of flat masks, mainly including roll material feeding, folding and pressing, nose bridge feeding, mask forming, mask cutting, ear strap feeding and welding, and finished product blanking Wait for the process, complete the blanking and other processes, and complete the entire production process from the raw material of the coil to the finished mask. The equipment adopts ultrasonic welding method, which is beautiful, hygienic and environmentally friendly. The mask produced is comfortable to wear, no pressure, good filtering effect, fits human face, and can be used in medical, electronics, mining, construction and other industries.

1. The SUNY GROUP one-to-two fully automatic flat mask machine production line is connected by one body machine and two ear strap machines. After the main body machine outputs the mask body, the mask body sheet is transported to the turning mechanism by the conveyor belt structure, the mask plate is turned over to the conveyor belt connected to the ear belt machine through the turning mechanism, and the mask sheet is transported to the ear belt machine through the conveyor belt. Above the first mask plate on the front, the mask piece is finally placed in the mask plate of the earband machine by pressing the air cylinder, and then the earband machine completes the earband welding and hemming of the mask to complete an earband mask product Production.

2. One-to-two automatic flat mask machine production line is mainly used for the automatic forming of flat masks: the whole roll of fabric is driven by the roller after being unrolled, and the fabric is automatically folded and hemmed; the whole roll of the nose bridge is unrolled and cut to length Then it is introduced into the edging fabric, the two sides are ultrasonically welded to the seal, and then the ultrasonic side sealing is carried out, and the shape is cut by a cutter; the mask is transported to the two mask ear strap welding stations through the assembly line, and the final mask is ultrasonically welded Forming; After the mask is made, it is transported to the flat belt line for collection through the assembly line.

3. Product features:

1. Using ultrasonic welding technology, the finished product is beautiful, hygienic and environmentally friendly.

2. The entire production line is automated from feeding, nose line insertion, edge sealing, and cutting of finished products, which is efficient and labor-saving.

3. The frame structure is made of aluminum alloy, and the key parts are made of stainless steel. The whole line has the characteristics of no rust, durability, easy cleaning, and beautiful appearance.

4. Computer PLC programming control, servo drive, high degree of automation. High stability, low failure rate and low noise.

5. Automatic tension control of raw materials to ensure balanced tension of raw materials.

6. Photoelectric (optical fiber) detects raw materials to avoid errors and reduce waste.

7. The machine is compact, small, and does not occupy space.

8. Production efficiency 80-100PCS/MIN.

4. Mechanical characteristics:

1. Automatic tension control of raw materials. Ensure that the tension of raw materials is balanced.

2. Photoelectric detection of raw materials to avoid errors and reduce waste.

3. It can produce one to four layers of mask body, and the surface length of the finished product conveyor belt is 1200MM.

4. This machine has the functions of total counting and batch counting, and the number of batch counting can be set arbitrarily.

5. Replacing the mold can produce masks of different sizes and styles.

6. The whole machine adopts aluminum alloy structure, which is beautiful and firm without rust. It adopts aluminum alloy structure with good finish and no rust.

The part that can be adjusted mechanically: the folding part can be adjusted; the welding point of the mask body can be designed; the mask can be made mechanically with 1-4 layers of cloth (active carbon material can be added in the middle).

5. Technical parameters:

(1) Equipment size: 7000mm(L)×4500mm(W)×1900mm(H) (not including receiving line);

(2) Appearance color: International standard warm gray 1C (DB standard color), according to this standard if there is no special instructions;

(3) Equipment weight: ≤5000kg, ground load ≤500KG/m2;

(4) Power supply: equipment 220VAC±5﹪, 50HZ, rated power is about 9KW;

(5) Compressed air: 0.5~0.7 MPa, use flow is about 300L/min;

(6) Operating environment: temperature 10~35℃, humidity 5-55%HR, no flammable, corrosive gas, no dust (cleanliness is not less than 100,000)

(7) Production efficiency: 80-120PCS/MIN;

(8) Equipment production qualification rate: 90% (except when the incoming materials do not meet the requirements and improper operation by employees)

(9) Equipment failure rate: 2% (referring to the failure of the equipment itself)

Six, equipment operation introduction

1. Start-up steps: turn on the power switch and the gas source switch, press the "reset" button on each device to reset the device, after the reset is completed, pull the device and "hand/auto" to the automatic state, and start the taps in order The machine, runner machine, lane divider, main machine, and the production line are fully automatic operation status. Manually only need to periodically check the ear strap, nose line, and material strap for lack of material, break the strap and deal with it in time.

2. Common troubleshooting: The device has a full Chinese touch screen. If an abnormality occurs during automatic operation, just press the abnormal information on the touch screen to eliminate the abnormality and press the "Start" button, and the device will continue to run automatically!

3. Touch operation instructions:

1. Automatic page

2. Manual page

In the manual state, you can click the corresponding key to perform manual operation, which is generally used for initial debugging, and manual operation is not used in the normal production process.

Three, I/O monitoring page

The I/O monitoring page can monitor the current status of each input and output point of the PLC, which is generally required for equipment maintenance.

Fourth, the parameter page

The parameter page (password required to enter) is the relevant parameter that needs to be set when the device automatically runs. Generally, it is set at the factory. It is not recommended to modify it. It must be modified. Please record the current parameters before modifying. Then press the parameter setting before modification.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231