Features and processes of precious metal refining and extraction equipment

Precious metal sorting, refining and extraction equipment is used to sort and refine precious metal gold silver palladium platinum from electronic waste containing precious metal chip components and anode mud. The purity of precious metals can reach 99.99%.

Features:

1. Wastewater can be discharged after treatment, and the treatment process is short. Environmentally friendly wet metallurgical process is adopted to reduce environmental pollution;

2. The purity of precious metals can be as high as 99.99%, and the extraction rates of precious metals such as gold, silver, palladium and platinum can be as high as 97-99%;

3. The operation process is highly automated, saving labor costs;

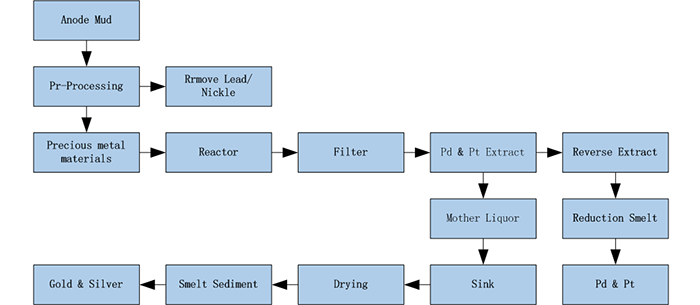

work process:

For the work flow of the precious metal sorting and refining and extraction equipment, the chips, north-south bridges, memory chips, integrated circuits, and plastic field effects that cannot be returned after disassembly are all components with the highest gold and silver content in the components. Adding ozone for roasting. The roasting slag uses solvent carrier, leaching copper, lead tin, hydrochloric acid medium to leaching gold platinum palladium, extract gold, platinum, palladium. Separately refine silver and palladium for SMD capacitors containing high silver and palladium. For gold-plated circuit boards and plug-ins, it is recommended to use environmentally friendly gold-releasing agents for rapid deplating and refining of gold.

For silver and palladium acoustic surfaces, metal-encapsulated triodes, and IC pins, the metal case is cut off, the chip is punched out, and the valuable metal is refined according to the chip and integrated circuit scheme. The electrolytic capacitors with high aluminum content are dry-rolled. After crushing, metal aluminum is directly smelted. For voltage-stabilizing diodes, partial variable-capacitance diodes, and other glass-encapsulated components, plastic-encapsulated light-emitting tubes are crushed and crushed to extract valuable metals. Electrolytic copper is produced, and palladium-containing circuit boards (both double-sided circuit boards basically contain palladium, and palladium is contained as a copper-plated substrate in lead holes as wires). The palladium is leached with acid, and then palladium is extracted and refined. There are many equipments in the whole refining process, which will not be described in detail here. If you have any intention, please feel free to contact us!

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231