Development process of dismantling and decomposing equipment for waste circuit board electronic comp

PCB circuit board, also known as printed circuit board, is the provider of electrical connection of electronic components. It is a substrate for assembling electronic parts, and a printed board that forms point-to-point connections and printed components on a common base material according to a predetermined design. Its development has a history of more than 100 years; its design is mainly layout design; the main advantage of using circuit boards is to greatly reduce wiring and assembly errors, and improve the automation level and production labor rate. According to the number of layers of the circuit board, it can be divided into single-sided, double-sided, four-layer, six-layer and other multi-layer circuit boards. The PCB industry belongs to the basic industry of electronic information product manufacturing. By seizing the opportunity of a new round of development of the global electronic information industry, focusing on the core of industrial structure adjustment, vigorously promote independent innovation to achieve the stable and sustainable development and transformation of China's printed circuit industry. Realize the upgrading of industrial product structure and technology, and form a competitive mass production capacity in advanced products and fields; form a complete set of high-end materials, equipment, instruments and service industries through independent innovation; Production and circular economy realize the development of the printed circuit industry to a low-carbon industry. Therefore, the use of pcb plays a pivotal role.

But on the other hand, with the rapid development of science and technology, the number of obsolete electronic and electrical products is increasing. The circuit board is the main body of electronic and electrical products, and it is also a difficulty in the recycling of waste electronic and electrical products. It has the characteristics of high chemical value and difficult recycling. Therefore, the recycling of waste circuit boards has attracted the attention of many research institutions at home and abroad. The recycling of circuit boards abroad pays more attention to the reuse of electronic components and prolongs the service life of electronic components as much as possible, so as to reduce the material demand for the production of new components and the waste discharge caused by the production process, and realize the saving of resources and energy. . my country's research on circuit board recycling started late, and most of the research is limited to the recycling of circuit board substrates, that is, the processing of circuit boards, and there are few studies on fine processing methods such as circuit board electronic component removal technology. The recycling method adopted is to directly shred and recycle the raw materials as a whole, which is a serious waste of resources and has a great impact on the environment. Based on the analysis and comparison of the existing circuit board electronic component removal technologies at home and abroad, this paper proposes a more perfect removal process for the differences in circuit board electronic components welding technology, removal force, and recovery value as follows:

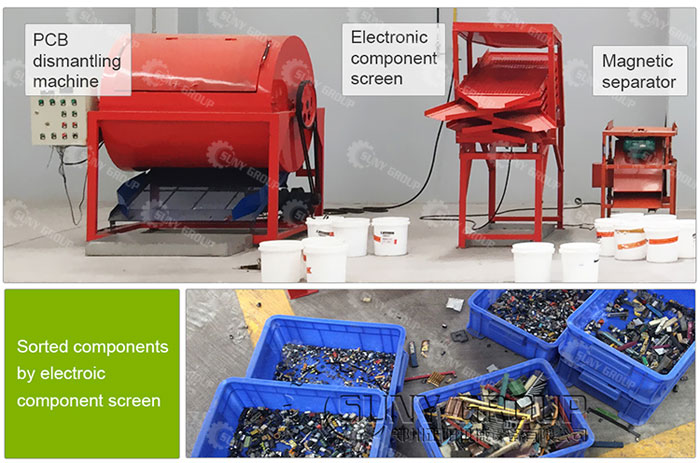

Circuit board disassembly equipment (board burning machine): old home appliance circuit boards, circuit boards, and defective products contain various electronic components such as capacitors, relays, transformers, etc., which need to be detined before the next step. The purpose of thermal de-tinning is to separate the electronic components and solder of the waste circuit board from the circuit board. The circuit board first enters the drum with sieve holes through the feeding port, and then the temperature is heated to about 150 ℃ through the electric heating device to loosen the tin on the circuit board. Wall friction, friction separates the solder, electronic components, and the circuit board on the circuit board. The separated solder and electronic components slide down through the channel to a multi-layer sorting screen, and the electronic components and solder are sorted out through the sorting screen. The circuit board after destining will enter the crusher through the conveyor for crushing. The tin collected during the pyrolysis process of tin removal is treated as a product for sale; the generated waste gas is mainly dust and waste methane. Solid waste, mainly including sieving out electronic components, water spray and waste activated carbon.

The tin balance analysis after dismantling the circuit board: the proportion of tin in the raw material is 3.0%, about 5400t/a. After treatment, it is distributed in the recycled tin, copper powder, resin powder and effluent dust. Among them, the tin content in the recycled tin is 149t/a, the tin content in the copper powder is 5020.2t/a, the tin content in the resin powder is 230.78t/a, and the heavy tin content is 0.0.2t/a. At the same time, the circuit board dismantling equipment (board burning machine) realizes the functions of automatic feeding, automatic dismantling and automatic discharging. Later tests show that the device is safe, reliable and safe to disassemble the electronic components of the circuit board, and the damage rate of the electronic components is low. .

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231