E-waste precious metals extraction equipment

In today's technology-driven world, e-waste is a growing concern. With the rapid development of electronic technology, the disposal of obsolete or damaged equipment has become a major environmental challenge. However, there are also opportunities within the challenges. E-waste contains valuable precious metals such as gold, silver, and platinum, which can be extracted and recycled using specialized equipment.

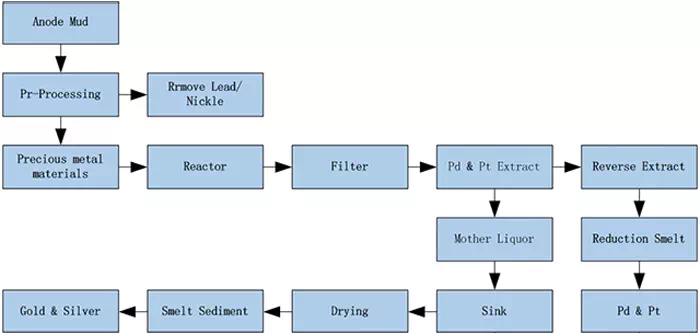

In order to solve this problem, SUNY GROUP developed advanced electronic waste precious metal extraction equipment. The machines are designed to safely and efficiently recover valuable metals from e-waste, minimizing environmental impact and maximizing resource utilization. Let’s explore some of the key features and benefits of this device.

Using to refine the precious metals (such as gold,sliver,platinum,palladium) from the kinds of e-waste.

After dismantling the elements can not be returned, such as chip, north and south bridge, storage chip, integrated circuits, field-effect plastic components are the highest collective material containing gold and silver meets element unified treatment, can use ozone roasting (ozone can completely destroy the formation of harmful combustion smoke), roasting residue using soluble carrier, leaching of copper, tin, gold platinum palladium hydrochloric acid leaching medium, extraction of gold, platinum and palladium. The chip capacitors highly contain silver-palladium-containing separate with high acid method independent refining silver palladium, for the gold-plated silver circuit board, plug ammonium polysulfide recommend using non-toxic methods to extract gold and silver plated quick retreat. For the silver-containing and palladium surface acoustic, metal packaging transistors, integrated circuits with special cutting machine pin chips were cut out of the metal case a chip, an integrated circuit solution to extract the valuable metals containing aluminum electrolytic capacitor for high-rolling after the dry , after crushing the direct smelting of aluminum metal, for Zener diode, varactor part, such as glass sealing components, plastic light-emitting tube was refine valuable metals after compacted crushed, for circuit board use acid leaching then by liquid electrolysis produce electrolytic copper, palladium-containing circuit boards (double-sided circuit board containing basic palladium, palladium as copper substrate contained in a wire guide hole) reuse acid leaching of palladium, and then extract palladium. The whole refining process include many equipments, here i will not state one by one.

E-waste precious metals extraction equipment

E-waste precious metal extraction equipment plays a vital role in solving the environmental challenges posed by e-waste. The equipment utilizes advanced separation technology, precise metal recovery mechanisms, and environmentally friendly processes to efficiently extract and recover valuable metals from e-waste. It not only minimizes the environmental impact of electronic waste disposal but also promotes the development of the circular economy. As a professional solid waste recycling solution provider and equipment manufacturer, SUNY GROUP has rich experience and complete technical equipment. If you have any needs, please feel free to contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231