How to recycle end-of-life lithium batteries?

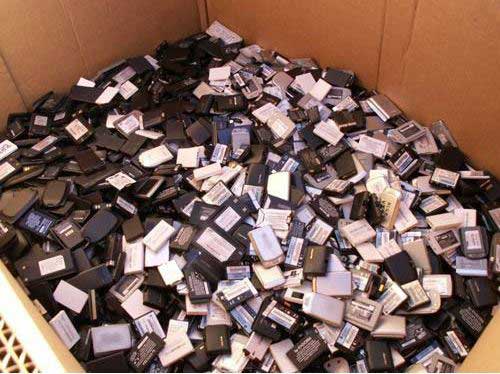

With the continuous use of electronic products, such as mobile phones and computers, the replacement is very fast, so the lithium batteries inside can actually be recycled and reused, but the current recycling rate of lithium batteries is very low, and a large number of waste lithium batteries are abandoned. It causes huge threats and pollution, and it is also a waste of resources. The analysis shows that lithium-ion batteries contain an average of 12%~18% cobalt, 1.2%~1.8% lithium, 8%~10% copper, and 4%~8% aluminum. Shell alloy 30%. How to deal with waste lithium batteries, recycling and utilization of waste lithium batteries?

1. The material is sent to the primary crusher by the conveyor for primary crushing, the material after primary crushing is sent to the secondary crusher through the conveyor for secondary crushing, and the crushed material of the secondary crusher enters the conveyor at the same time as magnetic separation. The equipment can sort out the iron in the material. After the iron is removed by the material conveyor and the magnetic separator, it enters the three crusher for fine crushing, and the material is crushed to powder.

2. The material in powder state enters into the cyclone separator from the negative pressure system for air filtration, and falls to the air separator through the fan, and is sorted by the air separator, so that the materials of different densities are stratified to obtain the metal separator. Selected, and all non-metals are brought into the pulse dust collector by the negative pressure system for concentration. The filtered exhaust gas will continue to be sent to the exhaust gas treatment equipment by the negative pressure system for air purification, so that it can meet the emission standard and then be discharged at high altitude.

3. The separation in the lithium battery recycling equipment consists of magnetic separation, air separation, etc. Magnetic separation can separate the ferromagnetic material in the crushed material; air separation can separate the powder and the lighter plastic diaphragm from the crushed material Sorted out, and at the same time, part of the volatile electrolyte adhering to the material was drawn out with the wind; the pretreatment and recovery of waste lithium-ion batteries is mainly to recycle waste lithium batteries, after discharge, use mechanical equipment for crushing, wind sorting, Pulverization, gravity separation, screening and other processes can effectively separate the active materials on the positive and negative pole pieces from the copper and aluminum foils.

4. Because the whole set of waste lithium battery recycling production line is equipped with dust removal equipment, because noise, dust leakage and exhaust emissions meet the relevant standards and requirements.

The above is the relevant introduction about the recycling of scrapped lithium batteries. If you have related needs or questions, you are welcome to contact us at any time, and we will reply to you as soon as possible.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231