Lithium-Ion Battery Recycling Overview of Techniques

As the demand for lithium-ion batteries continues to increase in various applications such as electric vehicles and portable electronics, the need for efficient and sustainable recycling practices has become critical. Lithium-ion battery recycling not only helps recover valuable materials but also reduces environmental impact. In this article, we will provide an overview of the different technologies and equipment used in the recycling process.

Battery classification:

The first step in lithium-ion battery recycling is to sort the batteries based on their chemistry, size, and shape. This process is critical to ensure that batteries of different chemistries are not mixed, as it could lead to safety hazards and inefficiencies in subsequent recycling steps. Automated sorting systems equipped with machine vision technology such as cameras and sensors are often used to achieve accurate and efficient battery sorting.

Battery discharge:

Before the recycling process begins, lithium-ion batteries need to be discharged to minimize the risk of thermal runaway or fire. Use specialized equipment such as battery dischargers to safely and effectively remove residual charge from batteries. These dischargers can handle a large number of batteries simultaneously and ensure complete discharge without damaging the battery.

Battery disassembly and broken:

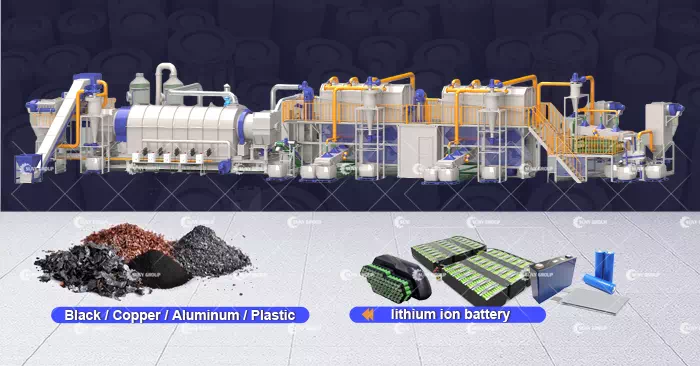

Lithium-lon Battery Recycling Plant

After the batteries are discharged, they are disassembled to separate the different components for further processing. Battery disassembly equipment includes mechanical shredders, crushers, etc. These machines break the battery into smaller pieces, making it easier to separate the material. Take safety precautions during this step to prevent any potential chemical reactions or short circuits.

Material recycling:

After the lithium-ion battery is disassembled, the positive electrode, negative electrode, electrolyte, separator, and other components need to be separated and recycled. Material recycling uses a variety of technologies, including:

Carbonization furnace carbonization process: After the waste lithium battery is broken, it can be separated into five parts: separator, copper foil negative plate, aluminum foil positive plate, casing, and electrolyte. After the battery is broken, a lot of black powder will fall out. Because there is adhesive on the copper foil and aluminum foil, part of the black powder will stick to the copper foil and aluminum foil, making it difficult to recycle. The separator material will not disappear, and the electrolyte will evaporate after the battery is broken. Drop part of it. Carbonization can also burn off the adhesive on the separator and the positive and negative plates, vaporizing the electrolyte, and thereby increasing the recycling rate of waste lithium batteries.

Mechanical crushing and sorting process: Mechanical technologies such as screening, magnetic separation gravity separation, and electrostatic sorting technology are used to separate shredded battery components based on their physical characteristics. This method is usually used to recover graphite powder, silicon powder, metal powder, etc.

Lithium-ion battery recycling plays a vital role in achieving a sustainable and circular economy. SUNY GROUP has been committed to the recycling of lithium batteries for many years, and the technology and equipment used in its recycling process have been continuously developed to improve efficiency and reduce environmental impact. By implementing advanced sorting, dismantling, and material recovery technologies, we can ensure the responsible and efficient reuse of valuable battery materials. Please feel free to contact us if you need it.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231