What is a copper wire granulator?

As demand for copper continues to increase and environmental concerns associated with the mining and refining processes grow, interest in recovering copper from various sources has surged. Among the available methods, the copper wire pelletizer stands out as a specially designed machine designed to efficiently convert scrap copper wire into high-quality copper pellets. This article takes an in-depth look at the working principle of the copper wire granulator and outlines its principles, processes and technical advantages.

Principle and process:

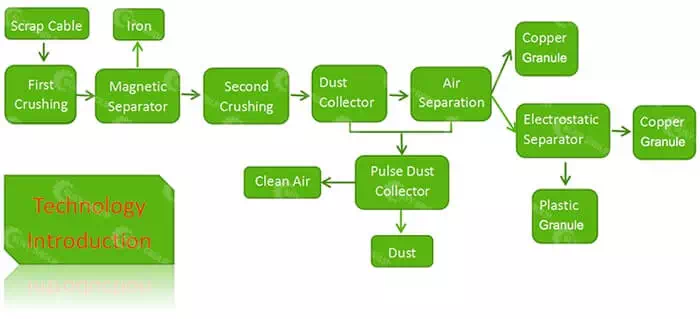

The copper wire granulator is an advanced equipment that uses mechanical and electrostatic separation technology to recover copper from waste wires, including telephone wires, electric wires and various waste wires. The process typically involves the following steps:

Working Principle Of Copper Wire Granulator

Wire pre-treatment: In order to prepare the wire for granulation, insulating materials such as plastic or rubber coatings are removed. This is usually accomplished by mechanically stripping away the insulation using a wire stripper. Alternatively, a shredder can be used for a more efficient and stable operation.

Granulation: After pretreatment, the wire is fed into the copper wire granulator. This machine uses rotating blades to cut the wire into small segments or particles, which is beneficial to the subsequent granulation process.

Separation: After granulation, mechanical and electrostatic separation processes are used. Common technologies include air separation systems and electrostatic separators. These methods exploit differences in properties such as density and conductivity to effectively separate copper particles from other materials, such as plastic or rubber residue.

Collection and packaging: Finally, the recycled copper pellets are collected and packaged for further processing or sale. Depending on the specific requirements of the end application, the particles can be further refined to achieve higher purity.

Copper Particles

Technical advantages:

Copper wire pelletizers have several significant technical advantages that make them popular in the recycling industry:

High Efficiency: The copper wire pelletizing machine is designed to process large quantities of scrap wire quickly and efficiently. These machines can process wires of various diameters and types, ensuring versatility.

Environmentally Friendly: The recycling process performed by the copper wire pelletizer significantly reduces harmful emissions and waste generation compared to traditional mining and refining methods. Some models are equipped with pulse dust collectors to ensure pollution-free operation.

Cost Effective: Using pelletizing technology to recycle copper wire offers individuals and businesses a cost-effective solution. It enables the recovery of valuable copper from discarded wires, providing a potential revenue stream and reducing waste management costs.

Copper wire pelletizers play a vital role in recycling scrap wire and promoting sustainable practices in the copper industry. Leading manufacturer SUNY GROUP designs and produces these machines that utilize innovative principles and technologies to efficiently convert scrap wires into high-quality copper granules. If you are interested or have any questions, please feel free to contact us.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231