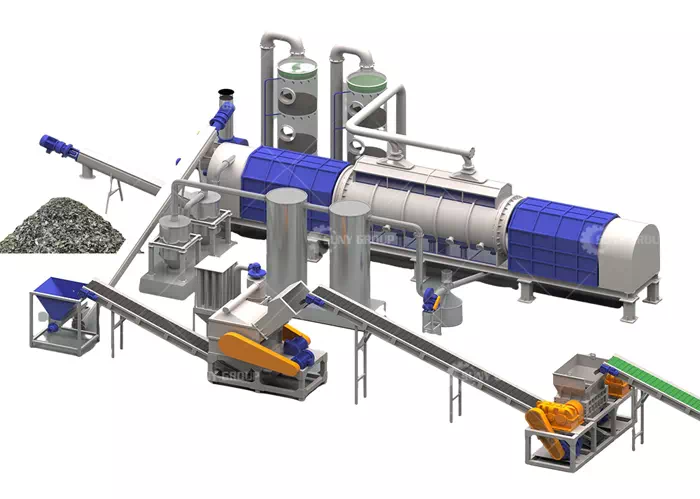

System for Producing Aluminum Briquettes from Shredded Beverage Cans

Aluminum beverage cans are widely used in the packaging industry due to their lightweight nature and durability, and their recycling value is becoming increasingly prominent. A high-efficiency recycling system can crush waste aluminum cans, remove paint and purify them, remove impurities, and finally press them into aluminum briquettes to realize resource recycling, energy saving, and environmental protection. This paper introduces a complete set of aluminum can recycling production system and its key equipment and process.

The process of the whole system is simple and clear, divided into five key steps: first, the raw material feeding link will be recycled waste aluminum cans into the crusher. The industrial crusher is designed specifically for aluminum cans and uses a high-torque drive to ensure that the crushing process fully adapts to the toughness and shape of the aluminum can material, increasing crushing efficiency and reducing equipment wear. After crushing, the aluminum cans are cut into homogeneous shreds for subsequent processing.

System for Producing Aluminum Briquettes from Shredded Beverage Cans

Immediately after that, the crushed material enters the continuous carbonization furnace, where the core of this process is efficient paint removal and purification. Through high-temperature treatment, the carbonization furnace can quickly decompose the coating and paint on the surface of aluminum cans, making the aluminum metal in the crushed material purer and laying a solid foundation for subsequent processing. Aluminum crushed material after carbonization treatment enters the magnetic separator, which can accurately remove ferromagnetic impurities, such as iron nails and iron filings, to safeguard the purity of the aluminum material.

Subsequently, the system is equipped with an eddy current separator to reject non-aluminum non-magnetic impurities, which is an extremely critical step that can effectively exclude other metal materials such as plastics, copper, steel, etc., to ensure the purity and quality of the finished briquette product. In order to further improve the cleanliness of the crushed material, the air flow screening or washing system (according to the customer's requirements) can carry out a second purification of the crushed material to remove the fine dust and impurities.

Finally, the layers of purified aluminum scrap are fed into a hydraulic metal briquetting machine. With a powerful hydraulic system, the machine compresses the aluminum scrap into dense aluminum briquettes, which are easy to store and transport, greatly improving the logistics efficiency and convenience of reprocessing. Users can choose different models of briquetting machines according to production scale and output requirements, from small pilot production equipment to large industrial production lines, to flexibly meet diversified needs.

Through refined process design and advanced equipment configuration, this system realizes the efficient closed loop of recycling from waste aluminum cans. It not only greatly improves the recovery rate and purity of aluminum resources, but also contributes to energy saving and emission reduction. If you are interested or in need, please feel free to contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231