Cable Scrap Granulator Machine

In the field of scrap metal recycling, waste cables have always been a key material type for recycling enterprises due to their high copper content and clear recycling value. However, the copper core inside cables is tightly encased by PVC insulation. Improper processing not only results in incomplete separation but also leads to copper loss and increased labor costs. The Cable Scrap Granulator Machine is a specialized solution designed precisely to address this challenge.

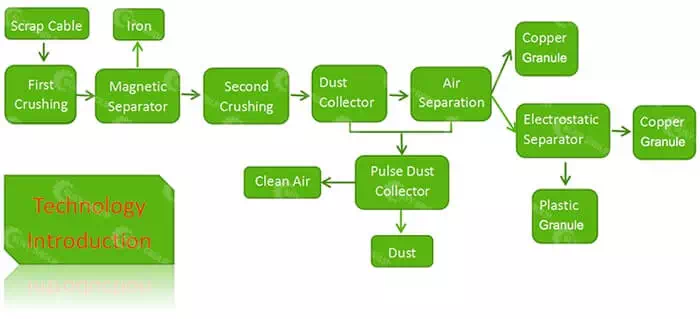

I. Process Flow

Cable Scrap Granulator Machine Process Description

The cable recycling production line employs a proven “mechanical crushing + physical separation” process route, suitable for various scrap cables, including wire harnesses, power cables, and communication cables. Upon entering the system, the material is first shredded by a crusher, thoroughly separating the copper core from the external PVC. The mixed material then undergoes air classification, utilizing the density and force characteristics differences between copper and plastic for preliminary separation. Finally, a linear vibrating screen performs precision screening, ensuring stable output of copper particles and plastic particles separately to guarantee product purity.

II. Core Technology

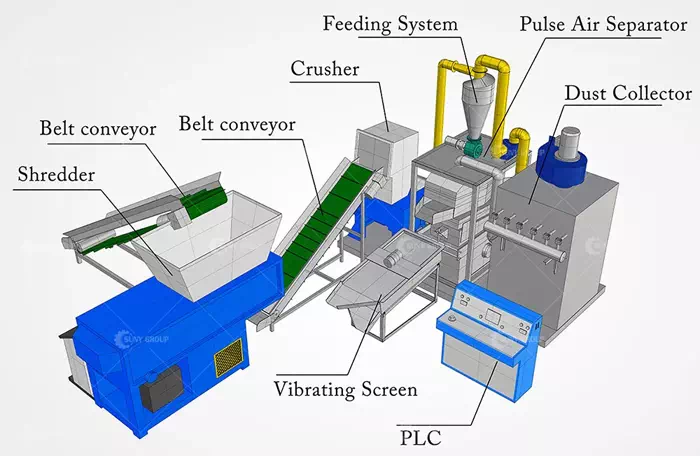

Cable Scrap Granulator Machine Structure

The complete cable shredding and recycling equipment primarily consists of a shredder, air separator, linear screen, and conveying system. The shredding equipment utilizes wear-resistant blades and an optimized rotational speed design, ensuring thorough shredding while effectively controlling dust and energy consumption. The air classification system is the core of the entire line. By precisely adjusting airflow volume and separation channels, copper particles rapidly settle under gravity while lightweight PVC is carried away by air currents, achieving highly efficient separation. The linear screen further grades the material, enhancing the purity of copper and plastic particles to provide stable quality for subsequent sales or reprocessing.

III. Value Advantages

This cable shredding, sorting, and recycling production line is widely adopted by scrap metal recycling stations, renewable resource processing plants, and cable manufacturing enterprises. Separated copper particles can directly enter smelting or trading processes, while plastic particles retain significant reuse value, enabling comprehensive resource recovery. The equipment features high automation and stable operation, reducing reliance on manual expertise and helping businesses lower long-term operational costs.

If you seek a cable recycling solution offering long-term stable operation, controllable sorting outcomes, and clear returns, this shredding and physical separation-based equipment warrants serious consideration. Contact us anytime for detailed pricing and video materials.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231