Copper Wire Granulator and Separator Machine

Copper is not only an important conductive material, its scarcity also makes every gram of recycled copper has a high value. Among many recycling equipments, copper wire crushing and separating machine, as the key equipment to realize efficient separation of copper and plastic, plays a pivotal role in the field of resource regeneration. This kind of equipment realizes the efficient treatment and reuse of waste wires through a set of systematic and intelligent process, which provides strong support for the development of circular economy.

Copper Wire Granulator and Separator Machine

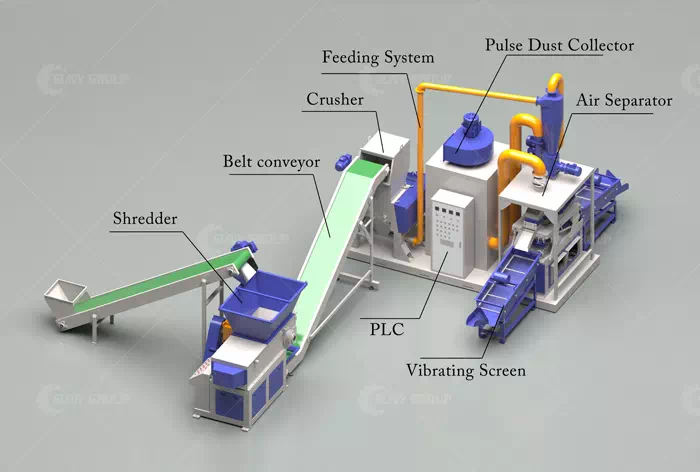

The main components of copper wire include an internal copper core and an external plastic or rubber covering. The goal of the copper wire crushing and separating machine is to completely dissociate these mixed structures and purify them separately to achieve a high recovery rate of over 99% copper purity. The whole process usually includes: automatic feeding, copper wire crushing, vibration screening, wind or electrostatic separation, dust and noise reduction treatment, and automation control. Among them, the feeding system ensures that the wires enter the pulverizer continuously and uniformly through belt conveyors or screw feeders; while the pulverizer adopts high-speed rotating blades to cut the wires into small particles and release the copper core.

The pulverized mixed particles will enter the vibrating sieving machine for initial classification, which utilizes the difference in particle density and particle size to initially screen the copper and plastic. Next, depending on the user's needs for recycling purity, the system can be equipped with an optional wind separation or electrostatic separation unit. The wind separation technology is suitable for coarse processing, through the air flow will be lighter plastic and heavier copper separation; while the electrostatic separation is more suitable for high-precision applications, the use of different conductivity of the material to achieve higher purity of the classification effect. In addition, the equipment is equipped with a pulse dust collector, acoustic enclosure and fan system to effectively reduce dust and noise, protect the health of operators and meet environmental regulations.

The whole set of equipment adopts PLC system for intelligent control, through the touch screen to realize one-button operation, fault alarm and operation monitoring, and some high-end models also support remote management and adaptive adjustment of parameters. With the advantages of high recovery rate, low energy consumption, small footprint, easy maintenance, etc., the copper wire crushing and separating machine has been widely used in renewable resources treatment plants, cable recycling enterprises and other fields. The modular design not only facilitates equipment upgrading, but also meets the demand for flexible configuration of production lines of different sizes. In the promotion of green manufacturing and resource recycling road, copper wire crushing and separating machine is showing irreplaceable value.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231