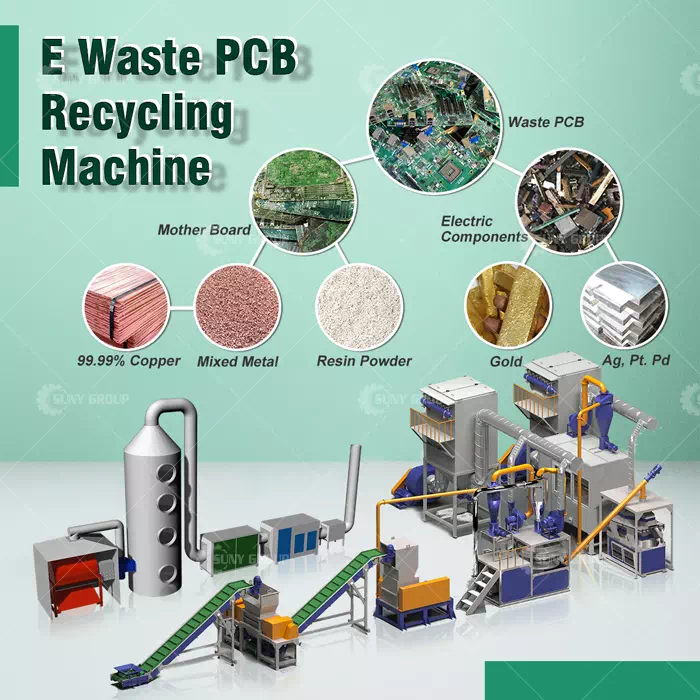

E-waste and PCB Recycling Machine

As the quantity of E-waste continues to grow, PCB, as a high-value part of recycling not only has economic significance but also relates to environmental protection and resource reuse. In the face of complex material structures and high-value-added metals, advanced recycling technology and equipment are particularly critical.

To realize efficient and environmentally friendly PCB recycling, modern recycling lines usually contain the following main links and their supporting equipment:

Preliminary dismantling and classification: fully automatic circuit board dismantler

The first step in the recycling process is to dismantle PCBs from e-waste. A fully automatic circuit board dismantling machine can efficiently separate circuit boards from housings, cables, components, etc. It reduces manual operation and improves safety and recycling efficiency.

Crushing and Separation: Crusher, Airflow Sorting Machine, and Electrostatic Sorting Equipment

The disassembled PCBs need to be further crushed to the appropriate particle size. After the professional crusher crushes the circuit boards, the plastic and metal are initially separated through the airflow sorting screen, and then with the help of electrostatic sorting equipment to accurately differentiate between copper, aluminum, and other metal and non-metal materials, so as to realize the effective separation of resources.

Metal extraction and recovery: precious metal refining equipment

PCB contains precious metals such as gold, silver, palladium, and so on. After sorting, the metal materials can further enter the precious metal refining equipment to extract high-purity precious metals for remanufacturing or sales, enhancing the overall economic returns.

Exhaust Gas Treatment System: Pulse Dedusting Equipment

A certain amount of dust and exhaust gases are generated during the entire crushing and refining process. An efficient pulse dust removal system not only purifies the air and safeguards the operating environment, but also ensures that the emissions are up to standard and meet environmental requirements.

Cost-effectiveness and environmental impact analysis

Despite the high initial investment, the automated PCB recycling system has significant advantages in terms of recycling efficiency, labor savings, and increased metal recovery rate. At the same time, the advanced dust removal system effectively controls pollutant emissions and reduces the negative impact on the environment, balancing economic benefits with social responsibility.

Technology-driven is the core power of E-waste recycling in the future, and SUNY GROUP can not only improve the resource recovery rate but also bring certain economic benefits to the enterprise by adopting highly efficient, environmentally friendly, and automated recycling equipment.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231