Lithium Ion Batteries Recycling Machine

In modern society, lithium-ion batteries have permeated every aspect of our lives. Whether it is new energy vehicles, smartphones, or energy storage power stations, all of them can not do without the support of lithium-ion batteries. However, with the large-scale application of lithium batteries, the problem of recycling used batteries has become more and more prominent. How to efficiently and environmentally friendly recovery of valuable metals from used lithium-ion batteries has become the focus of industry attention.

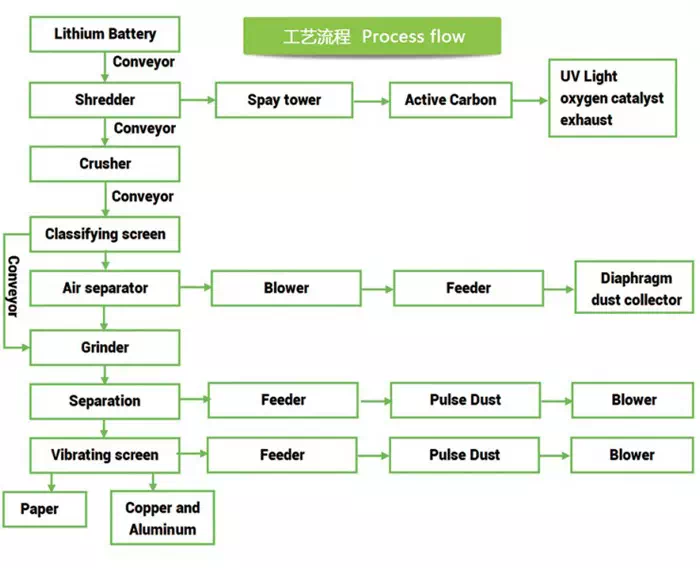

Lithium-ion battery recycling process

Lithium battery recycling process

The recycling process of lithium-ion batteries includes five main stages: collection → discharge → disassembly → separation → refining. First of all, through the safe collection and centralized storage and transportation of waste batteries to ensure the safety of subsequent processing. The discharge stage is to prevent the risk of electric shock and fire during the treatment process, so professional discharge equipment is needed to realize the rapid release of battery power. Then, it enters the dismantling stage, which utilizes specialized equipment for shell crushing and battery component separation. The separation stage mainly relies on physical sorting technology to effectively separate metal and non-metal materials. Finally, the refining stage recovers metal materials such as lithium, cobalt, and nickel through smelting or wet extraction technologies to complete the entire recycling cycle. Each link needs to be supported by matching efficient and safe equipment to ensure that the recycling process runs smoothly.

Lithium-ion battery recycling core equipment

Lithium Ion Batteries Recycling Machine

Among the many equipment, the crushing and separation system is the core part of the whole recycling process. After the waste battery is processed by a multi-stage crusher, it will gradually go from coarse crushing, and medium crushing to fine crushing, and finally achieve the purpose of releasing the internal materials of the battery. Subsequently, the continuous carbonization furnace carbonization equipment effectively removes organic matter and enhances the metal recovery rate through high-temperature treatment. The vibrating screening and air separation system further classifies and sorts the crushed materials screens out the fines, and improves the efficiency of subsequent separation. In the physical separation equipment, the magnetic separator is used to separate iron, nickel, and other magnetic materials to ensure the accuracy of metal classification, while the electrostatic separator realizes the efficient separation of metal powder and non-metallic materials through the difference of electric charge, laying the foundation for the subsequent metal recycling.

Lithium-ion battery recycling equipment not only improves the metal recycling rate but also significantly reduces environmental pollution, which is an important guarantee for the realization of sustainable use of resources. Through the combination of efficient equipment, the recycling process can run stably and efficiently, so that the limited resources can be regenerated and utilized. At the same time, the application of this equipment reduces the safety risks that may arise in the recycling process, provides solid technical support for the recycling industry, and brings certain economic benefits. If you need or are interested, please feel free to contact us for more information.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231