Machine for Removing Copper Winding Wire from Motors

The ability to swiftly and completely separate copper windings from the iron core within stators is crucial for determining recycling efficiency and the value of recovered copper. SUNY GROUP's motor copper wire dismantling and recycling equipment is widely used in the resource recovery of scrap motors, home appliance motors, and industrial motors.

I. Overall Equipment Design Concept

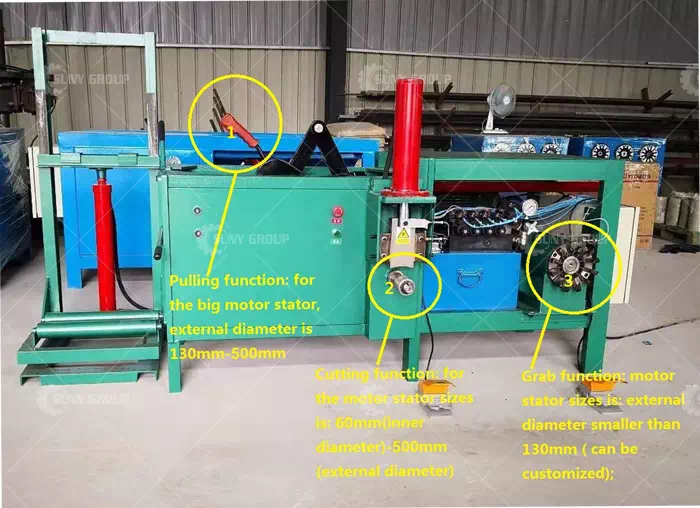

Centered on the principle of “mechanization replacing manual labor,” the motor copper wire stripping equipment employs a combination of cutting and hydraulic extraction to achieve rapid separation of stator copper wires. Featuring a compact structure and clear operational logic, the machine enables streamlined workflow from feeding to copper output, significantly reducing reliance on manual expertise.

The equipment is adjustable for different motor sizes, accommodating stators of various specifications. It is particularly suited for batch processing scenarios, representing a highly efficient upgrade over traditional manual dismantling methods.

Machine for Removing Copper Winding Wire from Motors

II. Core Working Principle

During operation, the equipment first processes the motor housing. Specialized structures enable rapid demolition of aluminum or cast iron casings, preparing the unit for subsequent stages. Next, the cutting system precisely severs the copper windings at one end of the stator.

During the extraction phase, hydraulic grippers or pulling claws securely grasp the copper windings. Stable hydraulic power then pulls the entire coil of copper wire out of the stator slots. Some high-end models also support stator halving or core separation functions, enabling more thorough separation of copper and iron to enhance recycling purity.

III. Application Value

Current motor copper extraction equipment primarily falls into two categories: integrated units and modular systems. Integrated machines combine shell breaking, cutting, and copper extraction functions into a single unit, offering simplified operation and a compact footprint. Modular systems pair cutting machines with copper extraction units, providing greater flexibility and suitability for processing mixed specifications.

Regardless of configuration, the core objective remains maximizing copper wire recovery efficiency while minimizing manual intervention and boosting output per unit time. For enterprises engaged in motor recycling, metal regeneration, or electronic waste processing, such equipment not only enhances operational efficiency but also significantly improves overall economic benefits and workplace safety.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231