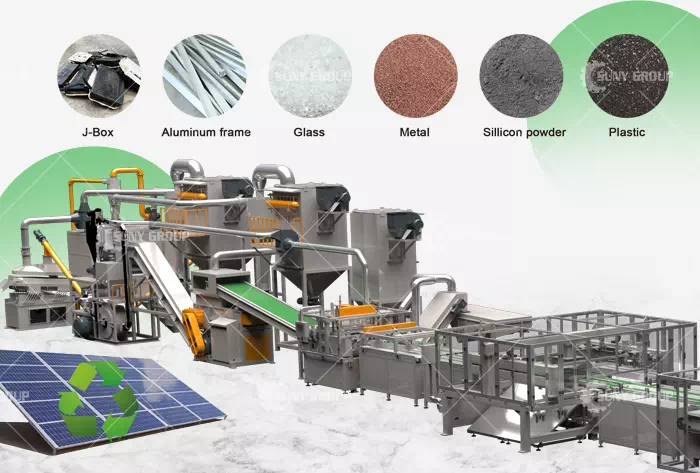

Machinery to Dismantle the Solar Panel and Recovery of Metals

With the rapid development of global solar power generation, many panels put into use in the early days are gradually entering the end-of-life period. This trend not only brings environmental pressure, but also prompts the rapid rise of the solar recycling industry. To realize resource reuse and reduce e-waste pollution, various kinds of efficient and automated machinery and equipment are playing an increasingly important role in the solar panel recycling process, and have become the key link in the whole recycling process.

Machinery to Dismantle the Solar Panel and Recovery of Metals

Solar panels are mainly composed of several layers of structure, including the surface layer of tempered glass, the middle EVA (ethylene vinyl acetate) encapsulation layer, the core crystalline silicon cell, the backsheet (usually plastic or aluminum materials), and the metal wiring part. Among these components, metals such as silver, copper, aluminum, and tin have high recycling value, especially silver, which is used in small but valuable quantities in PV cells as a conductive material. The high added value of these metals provides an economic incentive for solar panel recycling and drives the continuous optimization of recycling technologies.

In the specific recycling process, various specialized machinery and equipment operate in concert to form an efficient disassembly and sorting line. First of all, automatic disassembly systems are used to identify and disassemble structural components such as aluminum frames and power boxes of solar panels. These devices are highly automated and can effectively reduce labor costs. Subsequently, thermal desorption systems heat the panels to 300 to 600 degrees Celsius to soften or decompose the EVA encapsulation layer so that the glass and silicon wafers can be separated, and the commonly used equipment is a continuous carbonization furnace. After the initial disintegration is completed, the residual part of the panel is further crushed into small pieces by crushing and pulverizing equipment, which facilitates the subsequent fine sorting.

The sorting stage is a key step in metal recovery, where a variety of high-precision equipment comes into play. Magnetic separation equipment first removes ferrous impurities, followed by eddy current sorters to extract non-ferrous metals such as aluminum, and finally electrostatic separators to accurately separate plastics from metals. This complete sorting system ensures high purity recovery rates for all types of materials. Overall, the mechanical equipment not only improves the processing efficiency but also provides solid technical support for building a green and sustainable photovoltaic industry chain.

If you are interested in or need to know more about solar panel recycling equipment, please feel free to contact us.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231