How Do You Separate Copper Wire for Recycling?

Copper wire is a commonly used conductive material in modern industry with high recycling value. Through a reasonable recycling process, it can not only save resources but also effectively reduce environmental pollution. SUNY GROUP has developed highly efficient copper wire separation machinery and equipment, from crushing and separation to fine purification, to help realize the efficient recycling of copper wire.

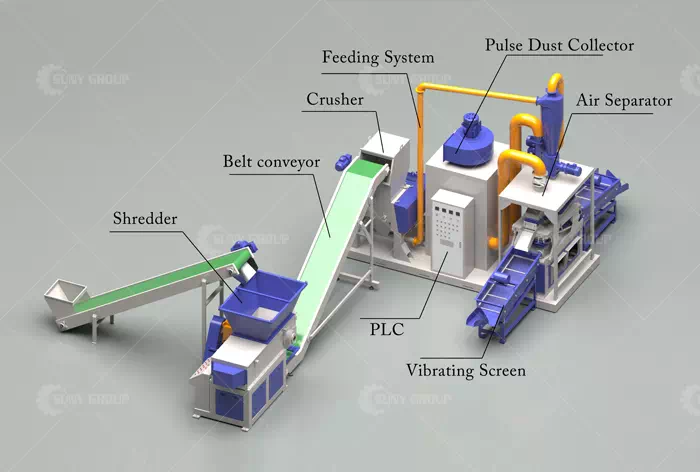

First of all, the core step of copper wire recycling is crushing and separation. This process is usually accomplished using a Copper Wire Granulator. The Copper Wire Granulator is designed to cut or pulverize copper wire into small particles that can be easily separated. The machine is highly efficient and quickly breaks down the copper wire into copper particles and a plastic jacket. In addition, the pulverizer is equipped with a dust removal system to ensure that no large amount of dust is generated during operation, enhancing the safety and hygiene of the working environment.

Scrap Copper Wire Recycling Equipment

Next, the copper wire is crushed and passed through an Air Separator for initial separation. The Air Separator utilizes the principle of wind power to separate copper from plastic based on the difference in density of the materials. During this process, the copper particles quickly sink to the bottom due to their higher density, while the plastic is blown up by the wind and floats to the other end of the machine due to its lightness. This type of separation is not only efficient but also environmentally friendly and non-polluting, making it a common technique in modern recycling processes.

To further improve the purity of copper, it also needs to be separated finely by an Electrostatic Separator. Electrostatic Separator utilizes the principle of electrostatic force to separate tiny impurities from copper through the attraction and repulsion of electric charge. This equipment is particularly suitable for the purification of fine copper particles and is capable of realizing high purity recovery rates. This link is a very important step in copper wire recycling, which can significantly increase the recovery value of copper.

In the whole recovery process, operation safety and equipment maintenance are the links that must be emphasized. Operators should wear protective equipment to ensure that the machine will not cause personal injury during operation. In addition, regular equipment maintenance and repair is also the key to maintaining productivity and long-term stable operation of the equipment. Through reasonable management and maintenance, the service life of the equipment can be extended, the failure rate can be reduced, and the recycling efficiency can be improved.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231