Solar Panel Waste Recycling Full Line Solution

It is predicted that by 2030, the total amount of discarded photovoltaic panels worldwide will reach millions of tons, which, if not properly disposed of, will cause tremendous pressure on the environment and resources. Therefore, building an efficient and environmentally friendly solar panel recycling system is not only an important path to achieve sustainable development but also pregnant with huge industrial opportunities.

Solar panel structure and its recycling value

Typical solar photovoltaic panels are composed of aluminum frames, tempered glass, silicon wafers, cell wafers, EVA adhesive film, back sheets, and junction boxes. These components contain a large amount of reusable resources such as aluminum, copper, silver, silicon, etc., and their recycling value is extremely high. The recycling rate of a standard solar panel can be more than 85%, which not only reduces the waste of resources but also can be used in remanufacturing, building materials, electronics, and other fields, with good environmental and economic benefits.

Solar Panel Recycling Technology Equipment

Analysis of the whole recycling process

An efficient solar panel recycling line usually consists of four major sections: disassembly, crushing, sorting, and pyrolysis/chemical treatment. Each section is carefully coordinated to ensure maximum material recovery and purity.

Dismantling section: separating frames and junction boxes

Using dedicated disassembly equipment, the aluminum bezel and junction box are first removed from the overall panel. This step directly recovers high-purity aluminum and copper wires, which facilitates subsequent processing and improves the overall recycling rate.

Crushing section: pre-processing the material structure

Coarse crushing equipment initially crushes the entire panel, followed by fine crushing equipment to further refine the particle size and create the ideal physical conditions for the subsequent separation process.

Separation and purification section: efficient separation of various materials

Magnetic separation equipment: used to remove iron impurities and improve the purity of materials.

Eddy current sorter: separates non-ferrous metals such as aluminum and copper with high recycling value.

Specific gravity sorting system: utilizing the density difference between silicon and glass, precise separation by heavy media.

Pyrolysis/chemical treatment section: Deep resource extraction

In order to deal with the EVA adhesive film in the panel, a pyrolysis furnace can be used for high-temperature decomposition to release the wrapped silicon and metal. Residual precious metals, such as silver, are extracted by a chemical leaching process to realize deep resource regeneration.

Visit us at SNEC PV 2025 to learn more!

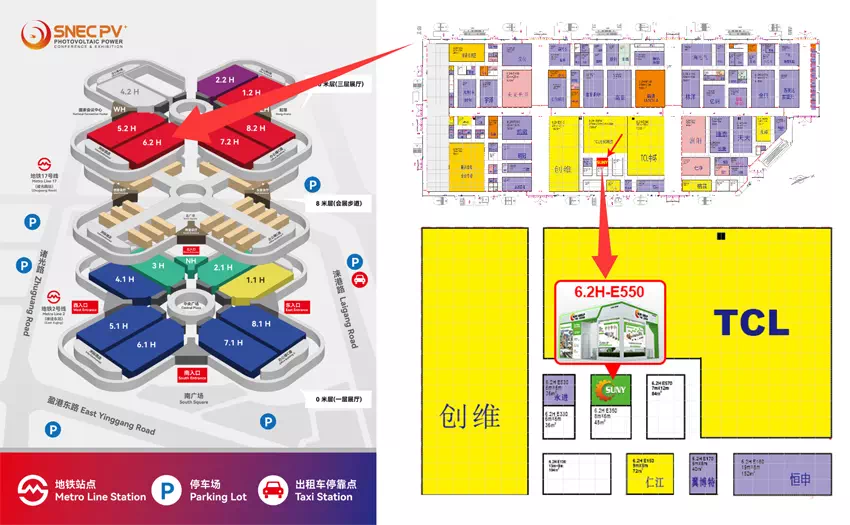

We invite you to visit SNEC PV POWER EXPO 2025 to learn about our solar panel recycling solutions in person. The show will take place from June 11-13, 2025 in Shanghai, China. Our booth number is 6.2H-E550, where we will display our core equipment and demonstrate the recycling process, which will help you understand the technical advantages and business value of the whole production line more intuitively.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231