What is the working process of lithium-ion battery recycling machine?

With the strong development trend of new energy vehicles in recent years, the scrapping standard of the power battery, which is the core of the power of new energy vehicles, is that the battery capacity is less than 80%, which means that the power of new energy vehicles must be replaced every 3 to 5 years. Battery. Among them, the scrapped power battery of pure electric passenger cars and hybrid passenger cars will reach 170,000 tons in 2022. Therefore, the recycling of waste power batteries has become the focus of the industry. How to deal with waste lithium batteries?

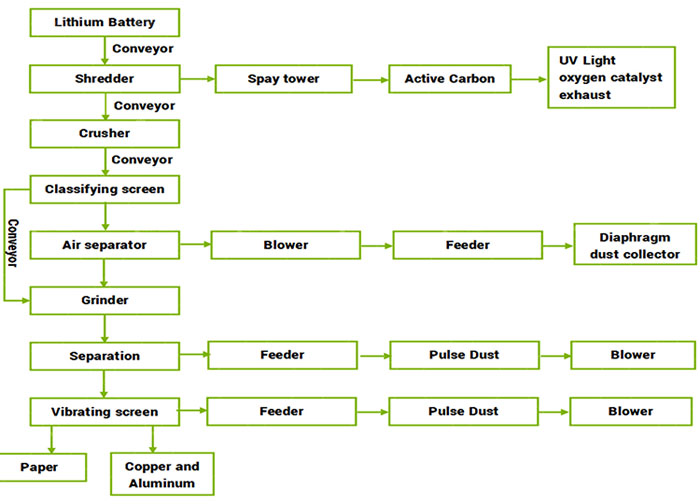

1. One-time vibration transportation: The battery waste is placed in the vibrating feeder and forwarded to the coarse crusher, and during the conveying process, the black powder vibrated from the battery waste is sucked into the cyclone feeder by negative pressure. Recycle;

2. Coarse crushing of battery waste: The battery waste is roughly crushed by a coarse crusher, and the size of the battery waste after coarse crushing is 2-3cm;

3. Secondary vibration transportation: place the roughly crushed battery waste in the vibrating feeder and forward it to the sorting box, and during the conveying process, the black powder vibrated from the battery waste is sucked into the cyclone by negative pressure. Recycling in the feeder;

4. One-time separation of battery waste: In the sorting box, the battery iron and aluminum shell with a large specific gravity is separated from the large specific gravity material outlet of the sorting box, and the battery waste with a small specific gravity enters the fine specific gravity material outlet from the sorting box. crusher;

5. Fine crushing of battery waste: The motor waste is finely crushed by a fine crusher, and the size of the battery waste after fine crushing is 2-5mm;

6. Secondary separation of battery waste: The finely crushed battery waste is in the gravity separator, and the copper particles with a large specific gravity are separated from the large specific gravity material outlet of the gravity separator, and the battery waste with a small specific gravity is separated from the gravity separation. The small specific gravity material outlet of the machine enters the pulverizer, and at the same time, the black powder from the battery waste after being finely crushed is sucked into the cyclone feeder for recovery by negative pressure;

7. Milling and crushing of battery waste: The battery waste is milled and crushed by a mill, and the size of the battery waste after grinding and crushing is less than or equal to 1mm;

8. The third separation of battery waste: the battery waste after grinding and crushing is in the classifier, and the finer black powder will be sucked into the cyclone feeder by negative pressure from the discharge port of the classifier for recycling. Coarse-sized battery waste enters the gravity separator from the coarse powder discharge port of the classifier;

9. The fourth separation of battery waste: in the gravity separator, the copper particles with a large specific gravity are separated from the large specific gravity material outlet of the gravity separator, and the aluminum particles with a small specific gravity are separated from the small specific gravity material outlet of the gravity separator. At the same time, a small amount of black powder is sucked into the cyclone feeder by negative pressure for recovery.

The above is the whole process of lithium battery recycling. Scrap lithium batteries, if they can be recycled scientifically and effectively, are actually an invisible treasure. SUNY GROUP has been engaged in lithium battery recycling equipment manufacturing industry for many years, and has a complete set of scrap lithium battery recycling. technology and solutions, and lithium battery recycling equipment can be customized according to customer needs. If you have any questions or needs, please feel free to contact us at any time.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231