Causes of the improper seal of the wet tissue machine

The main reasons for the weak seal of the wet tissue machine are as follows.

(1) The heat-sealing temperature of the wet tissue packaging machine is not enough, as long as the heat-sealing temperature is increased appropriately, the problem can be solved.

(2) The surface of the heat-sealing knife is not flat enough. The heat-sealing knife is divided into upper and lower pieces. Usually the thermocouple is installed in it to sense the temperature transfer. There are three screws on the heat-sealing knife, and the middle screw supports and To strengthen the blade, the other two screws are equipped with pressure springs and gaskets, which are mainly used to adjust the pressure of the heat-sealing knife. There are two springs for the upper and lower blades. The main reason for the uneven surface of the heat-sealing knife is the middle. The screw is inclined, not horizontal.

Or the pressure spring of the heat-sealing knife on the wet tissue machine is uneven. The solution is to re-correct the position of the middle screw to make it in a horizontal state. If the upper and lower heat-sealing knives are unbalanced, the pressure spring must be adjusted. Adjust to a moderate degree. When the spring is retracted outward, the heat-sealing knife will fall downward, and when the spring of the lower blade is tightened upward, the heat-sealing knife will move upward.

(3) The uneven pressure of the cold-pressed rubber wheel of the wet tissue packaging machine will also cause this poor sealing. The solution is roughly the same as the first case.

Three-layer meaning: When performing a peel test on the seal, half of the seal is firm and half of the seal is separated, and the sealing quality of such a packaging bag is still unqualified. Because the contents are easily leaked out by extrusion during storage and transportation, this situation often occurs when the composite lining is OPP or blow molded PE.

There are two main reasons for the improper seal of the wet tissue packaging machine.

(1) The adjustment of the uneven pressure of the heat sealing knife or the uneven pressure of the cold pressing knife is exactly the same.

(2) The surface of the heat-sealing knife is not flat enough. Refer to the corresponding solution for the second type of faulty seal.

2. The fuse of the wet tissue packaging machine is blown

The main function of the sealing machine motor is to drive the gearbox and various parts of the gear transmission. Sometimes the sealing machine will make a "squeak" sound when it is started, it will not work normally, and even the fuse on the live wire will blow. The power supply should be checked first when troubleshooting Whether it is normal, then cut off the power supply, check whether the switch is damaged with a resistance file, and check whether the circuit and the motor are short-circuited.

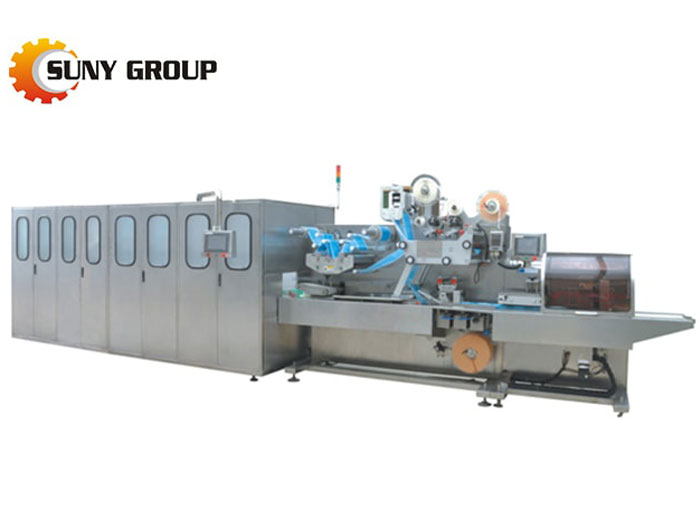

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231