Alastic Aluminum Separator Machine

The aluminum-plastic separator is a recycling processing equipment for the recycling of renewable resources. It can recycle waste aluminum-plastic materials, separate aluminum from plastic, and then achieve the purpose of recycling.

The scope of application of the aluminum-plastic separation machine: scraps from pharmaceutical factories, aluminum-plastic panel factories, food and beverage factories and other aluminum foil packaging industries, as well as waste soft packaging bags, capsule boards, toothpaste skins, and Wahaha bottles in the waste station.

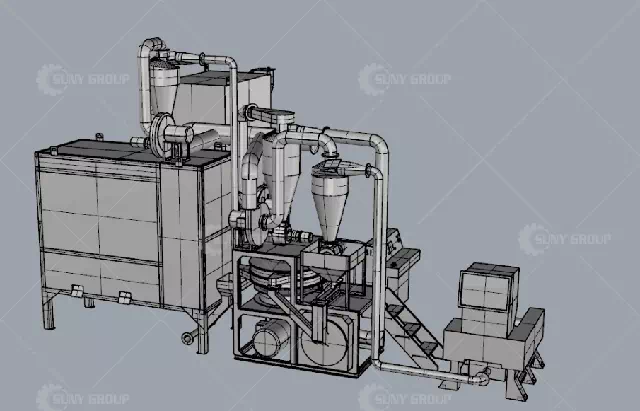

Aluminum-plastic separator structure

Working principle:

The aluminum-plastic crushing and sorting equipment adopts the method of physical crushing and electrostatic separation to separate aluminum and plastic. First, the aluminum-plastic waste is roughly crushed into flakes below 10mm by a knife-cut crusher, and then enters a high-speed water-cooled turbine pulverizer to finely crush the flakes. It is made into a mixture of aluminum and plastic, and the material that meets the requirements is screened by a rotary vibrating screen to separate the aluminum and plastic by the principle of an electrostatic separator, and the unqualified material is returned to the mill for further crushing. The loss of aluminum and plastic is very low, and the recycling rate of aluminum is close to more than 99%. This equipment adopts completely dry physical separation, which will not cause secondary environmental pollution.

The core machine is the electrostatic separator, which uses the difference in conductivity of aluminum-plastic materials, the electrostatic force generated in the high-voltage electric field, gravity, and centrifugal force to effectively separate and sort aluminum and plastic.

Advantages: The aluminum-plastic sorting machine has a high degree of automation, saves time and labor, and the whole process mainly uses electricity. It does not use chemicals or heating, and has no impact on the environment. This separation method is being promoted and popularized. After the sorted plastic is purified, the quality and color will not change. The plastic is in the form of fine particles and can be directly processed to make plastic products. The loss of aluminum is very low, more than 99.9% of the aluminum is extracted, and the activity of aluminum is not affected. Aluminum particles can be directly processed into industrial aluminum powder such as aerated aluminum powder paste and aluminum powder for fireworks.

The above is the relevant introduction about the plastic and aluminum separation machine. For some aluminum-plastic waste, the aluminum-plastic separation and recycling can be realized through the aluminum-plastic separation machine. If you have a large amount of aluminum-plastic waste to deal with, you can contact us directly, and we will formulate a targeted aluminum-plastic separation solution based on your material characteristics.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231