A detailed introduction to the separation and recycling of aluminum-plastic waste

Aluminium-plastic separator for medicine plate, which can professionally separate domestic or imported aluminium-plastic medicine plate, with fast separation speed and high efficiency; general-purpose aluminium-plastic separator for flexible packaging, this equipment can separate all kinds of aluminium-plastic composite films, such as food packaging bags, which is beneficial to Le Bao, etc.; aluminum-plastic panel separator, this equipment is specialized in separating aluminum-plastic panel scraps and scraps, and every aluminum-plastic panel manufacturer has the generation of aluminum-plastic panel waste.

The waste aluminum-plastic film, aluminum-plastic board, and medicine board aluminum recycling and processing equipment have the characteristics of low noise, large production volume and strong innovation ability. The aluminum of aluminum-plastic wastes such as aluminum-plastic panels purchased by the aluminum-plastic separator can maintain the quality of the original aluminum, and can take into account the advantages of recycling plastics, which has great economic advantages.

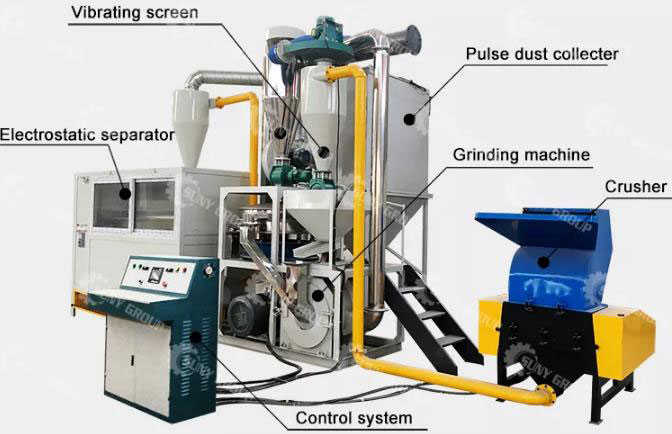

1. Detailed explanation of the production process and machinery and equipment of aluminum-plastic separation equipment

1. Aluminum-plastic separation pulverizer

The aluminum-plastic shredder adopts special steel and specially-made blades, which are durable. The blade installation design is retractable and adjustable. It can be repaired several times after being dull, and it can be used repeatedly and has a long service life. The aluminum-plastic crushing mobile cutter head is a stepped scissor design, which makes the cutting evenly decomposed by force, resulting in a multiplication of the cutting speed. The raw material of the cutting seat is high-quality alloy steel, which is rigid and flexible, and is not easy to crack or damage. It is screwed with high-strength steel plate screws (grade 8.8), and the structure is reliable and durable. The main body of the aluminum-plastic crusher is the high-quality alloy structural steel raw material of the thick-walled tube, which can prevent the physical properties from being harmed by the long-term crushing of the raw material. The spindle bearing center and double inner hole of the aluminum-plastic crusher are processed by a high-precision coordinate CNC lathe in one production process to ensure that the difference between the coaxiality and flatness does not exceed 0.05MM. 2 times of flow processing, strong interchangeability of components and good precision.

2. Main features of aluminum plastic crusher:

The main shaft bearing has a large rotation diameter, the volume of the crushing chamber is large, and the unique spiral bevel gear design has a strong rushing force for hollow products. The shell is made of solid welded steel structure, which has universal practicability. According to the different crushed raw materials, our company can provide different designs of motor rotors, and can also crush plastic inlets, pipe fittings, aluminum profiles, plastic sheets, plastic films and their block-shaped nozzle materials. The model has many advantages such as economic development, durability, easy cleaning, and long service life. Large and medium-sized hollow thick-walled plastic products, large and medium-sized hollow packaging boxes, large and medium-sized plastic boxes, plastic frames, refrigerator casings, TV plastic casings) plastic products can be immediately invested and smashed without dissolving or squeezing them.

2. Application scope of aluminum-plastic separation equipment:

This series of new aluminum-plastic grinding equipment is a series of grinding equipment developed by our factory to digest and absorb the research and development of new technological products from all over the world. It is used for PVC plastics with low to medium strength, PE with high density, or other aluminum plastics after successful trial grinding. It has been confirmed by the actual operation of the plastic product technology professional processing plant that the grinding pellets are added with 20%-30% calcium bicarbonate in the production and processing telephone return visit, and the organic chemical process performance of its products will maintain the newly upgraded various index values. And the production volume can reach 300kg. Therefore, this aluminum-plastic grinding equipment is a machine and equipment for plastic products factories to reduce costs and save expenses and deal with the accumulation of waste.

3. Characteristics of aluminum-plastic separation equipment:

This aluminum-plastic grinding equipment is a new type of grinding equipment independently developed by our factory. Its characteristics are as follows:

(1) Compared with similar grinding equipment, the production volume has been greatly improved under the same output power (20%-50% high output). save energy;

(2) The dust collector equipment has been improved, and the environmental pollution of smoke and dust has been reasonably reduced;

(3) The design scheme of feeding the main centrifugal fan reduces the labor efficiency of the actual operating staff;

(4) The door cover of the server can be opened, which is convenient for maintenance and disassembly and replacement of CNC blades;

(5) The use of feng shui double cooling can reduce the operating temperature in the human body, and the materials developed are not subject to change. In addition, it is also beneficial to the grinding of heat-sensitive plastics, and can be used for grinding a part of PE and ABS.

4. Principle of aluminum-plastic separation equipment:

Part of the work of this equipment is the spindle. Part of the high-speed particles is broken after colliding with the tooth block, and is drawn out by the air intake, while the large particles collide again and are drawn out after being broken. In this way, the load of the spindle is reduced, the high efficiency of grinding into powder is improved, and the granular material can be uniformly cooled.

5. Advantages of aluminum-plastic separation equipment:

The low temperature is a key advantage of this device. According to the thermal power equivalent: the calorific value of 860 kcal is converted into 860 kcal after the work is done per hour. The device is external exhaust. The exhaust air volume reaches 50 meters/KW, and most of the calorific value is brought by the temperature difference between the inlet and outlet air. A small part of the heat generated is handled by the cooling water. It is stipulated that the inlet temperature of cold water should not exceed 25°C, and the temperature of inlet and outlet water should not exceed 45°C. In summer, the cooling water should be appropriately increased to reduce the temperature.

2. Main parameters of aluminum-plastic separation equipment:

Number of cutterheads: 1, diameter: 483 mm ± 1 mm

Gear block: 1 to 12 pieces (high-quality aluminum alloy steel, strength 50°-58°)

Blade: 24 pieces (high quality steel, strength 52-55)

Main motor rated power: 2950r/min

Main motor rated power: 37KW, applicable V-belt: B type, 2007mm

Centrifugal fan: model specification 9-19, 4#, suitable for motor 3KW

Air shutoff device: model specification ZGF, applicable motor 0.75KW

Production capacity: PVC20-100 mesh 180-285kg/h

Appearance specifications: full set of equipment (length*width*height) 5900*1450*2900

Net weight of the whole machine: 1205kg

3. High voltage electrostatic sorting equipment:

The high-voltage electrostatic separation equipment adopts a thorough mechanical equipment separation method, without organic chemical debugging and separation liquid, etc., and a thorough dry test separation, the separation purity rate is above 95%, and 99.9% can be achieved. It can separate the leftovers of aluminum-plastic panels and pill packaging materials, Wahaha Group seals, aluminum-plastic pipes, waste wires and cables, circuit boards and other mixtures of metal materials and plastics. It belongs to the new environmental protection machinery in the environmental project.

1. Brief description of high voltage electrostatic separation equipment:

Electrostatic separation equipment (electrostatic separator) is a green and environmentally friendly electrostatic separation equipment developed and designed by our company in digesting and absorbing various electrostatic separation technologies from all over the world. According to many years of experiments and basic theoretical analysis, the best screening practice As a result, the residue after screening can be less than 1%, that is, the screening efficiency can reach more than 99%.

2. Application scope of high voltage electrostatic separation equipment:

The standard series of green and environmentally friendly electrostatic separation equipment (electrostatic separator) can not only screen various metal materials and plastics or other residues, such as aluminum-plastic, waste printed circuit boards (copper and PCB), waste wires and cables, etc. It can also screen all kinds of PET, PVC, PP, PS and other plastics, because big cities need to replace a lot of waste every year, and electrostatic separation equipment (electrostatic separator) can make this kind of waste and waste use, There is no secondary pollution, environmental protection and environmental protection screening method, and the project investment can be recovered quickly. Electrostatic screening is also a good way to get rich.

3. Key performance parameters of high voltage electrostatic separation equipment:

1. Production capacity: 1-10 tons/day (related to the quality/volume ratio of different raw materials)

2. Separation of raw materials: various metal materials and plastics or other residues, such as aluminum-plastic, waste printed circuit boards, waste wires and cables, iron ore screening, various PET, PVC, PP, PS and other plastics.

3. High screening efficiency: the residue after electrostatic screening can be less than 0.1%, and the screening purity can reach 99.9%.

4. Volume: 1.7 meters long, 1.5 meters wide and 2.5 meters high.

5. Power supply system: 380V AC/2A/50Hz and 220V lighting power.

Fourth, high-efficiency and energy-saving aluminum-plastic separator, separation equipment, separator application fields:

Energy-saving aluminum-plastic separators, separation equipment, and separation functions separate various, electrical conductor chemicals from conductive medium chemicals, metal materials and non-metal materials, and are mainly used to waste printed circuit boards (copper and PCB), various Various medicine boards, aluminum-plastic boards, food bags, milk bags, whitening toothpaste skins, bottle stoppers of Wahaha Group, aluminum-plastic tubes, aluminum-platinum paper, metal material concentrators, etc., the actual effect of separation is remarkable. Because big cities need to replace a lot of waste every year, the use of aluminum-plastic separation equipment can make use of this waste and waste without secondary pollution. .

5. Characteristics of energy-saving aluminum-plastic separator, separation equipment and separator:

1. Waste aluminum-plastic recycling equipment (aluminum-plastic separator) can separate aluminum and plastic, and achieve the purpose of development and utilization, with high economic benefits. And no dust and no secondary pollution.

2. The machinery and equipment is composed of multiple machines, feeding materials at one time, carrying out multiple machines, coupled with automatic transportation, sound insulation and noise reduction technology, refrigeration systems, etc., to achieve the separation and acquisition of metal materials and plastics.

3. The waste aluminum-plastic recycling and processing equipment has the characteristics of low noise, large production volume and strong innovation ability. The aluminum of aluminum-plastic wastes such as aluminum-plastic panels acquired by the aluminum-plastic separator can maintain the quality of the original aluminum, and can acquire the advantages of plastics and other advantages, which can cause great economic benefits.

4. The aluminum-plastic recycling equipment (aluminum-plastic separator/aluminum-plastic separation equipment) adopts high-voltage electrostatic separation technology, and the utilization rate of metal materials is higher, and the utilization rate of metal materials is over 98%.

5. The machinery and equipment also use the three-in-one dust removal device independently developed by our company. This dust removal device has three levels of dust removal: cyclone dust removal, bag dust collector and air purifier dust removal, which reasonably solves the problem of smoke and dust environmental pollution.

Attachment: Industry prospects of high-efficiency and energy-saving aluminum-plastic separators, separation equipment, and separators: With the development trend of the times, aluminum-plastic raw materials in various industries in people's daily life have been widely used, but no effective circulation system has been obtained. Reuse. The waste aluminum-plastic processing equipment developed by our company can be applied to aluminum-plastic panels including building decoration materials, aluminum-plastic panels inner corners, aluminum-plastic pipes, medicine boards, composite aluminum-plastic cables, toothpaste skins, Wahaha bottle seals, composite types Crushing and separation of various aluminum-plastic mixed raw materials such as aluminum-plastic sealing.

6. Principle of high-efficiency and energy-saving aluminum-plastic, separation equipment and separator:

There are PVC materials in the aluminum-plastic polymer material, plus the distinctive two- to four-chamber structure, and the inner surface has a sub-film of aluminum alloy profiles, which has the effect of heat insulation. The method of heating and separation is to use this feature to solve the problem. However, there are other harmful substances such as dust and taste, which are not ideal; and some applications of chemical liquid separation are even less environmentally friendly. The special-purpose crusher crushes the aluminum-plastic raw materials to a particle size of less than 1.5 mm. Because the softening value of the two raw materials is very different, such mixed particles are very suitable for the separation of the DC concentrator. In addition, there is a dust removal device. High separation purity. The biggest advantage of this production line is that the separated aluminum particles and plastic particles can directly enter the sales market, which cannot be achieved in other ways.

Seven, energy-saving aluminum-plastic separator, separation equipment, separator characteristics:

1. The automation program is high, the actual operation is simple and easy to use, and the performance is stable.

2. Low power consumption, low noise, small footprint and no environmental pollution.

3. The high efficiency of electrical separation is 99%, and the finished product can be sold directly.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231