Hammer Metal Crusher Operation Precautions

1. The fixed operation of the crusher should be fixed on the cement foundation. If the working location is changed frequently, the metal shredder and the motor should be installed on the base made of angle iron. If the crusher is powered by a diesel engine, the power of the two should be matched, that is, the power of the diesel engine is slightly larger than that of the crusher, and the pulley grooves of the two should be consistent. The outer end face of the pulley should be on the same plane.

2. Before starting the machine, it is necessary to check whether the connecting bolts of each part of the metal crusher unit are tightened, whether the tightness of the transmission belt is appropriate, and whether the power cord is in good condition. Whether the motor shaft and the pulverizer shaft are parallel.

3. Check whether the hammer is in good condition, whether the aperture of the screen is suitable, and whether there is any damage. Drag the belt by hand to check whether the spindle rotates flexibly and whether there is jam, bump or friction.

4. After starting the machine, let the equipment idle for 2-3 minutes to check whether the rotor is turned correctly and whether the sound is normal. It can work only after it rotates smoothly at the rated speed.

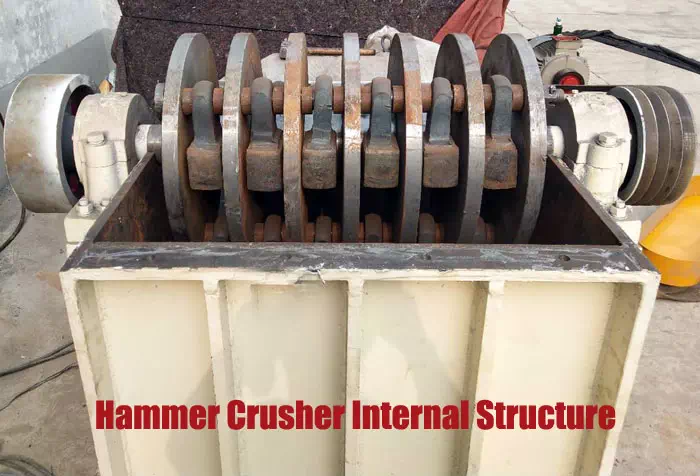

Hammer Crusher Internal Structure

5. Pay attention to the operation of the crusher at any time during the work, and the feeding should be even, so as not to block the boring car, and do not overload the work for a long time. If it is found that there is vibration, noise, high temperature of bearing and body, material spraying out, etc., it should be stopped immediately for inspection, and the work can be continued after troubleshooting.

6. The broken materials should be carefully checked, and foreign objects such as stones should not be mixed, so as not to damage the machine.

7. When the machine is running, the operator shall not leave the unit, and shall not disassemble the machine during operation to observe the working conditions in the crushing chamber, and maintenance tools shall not be placed on the machine or filler.

8. The operator should not wear gloves. When blockage occurs, it is strictly forbidden to put hands into the filling bucket. When feeding, they should stand on the side of the grinder to prevent the rebound debris from hurting the face.

9. Don't stop the machine immediately after the work is over, it should be idling for 2-3 minutes so that the materials in the machine can be completely discharged. Cleaning and maintenance should be carried out after shutdown.

10. The hammers of the metal crusher are the main wearing parts. After wear and tear, the whole set of hammers should be replaced at the same time, whether the edges and corners are exchanged in the same direction or by turning around. When replacing new hammers, the whole set of hammers should be replaced at the same time. A single hammer is traded in for a new one. The screen is also a vulnerable part. If part of the screen is damaged, it can be repaired by riveting. If it is seriously damaged, it needs to be replaced with a new screen.

11. After 300 hours of operation of the pulverizer, the bearings should be cleaned and the oil should be replaced. When parking for a long time, the belt should be removed.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231