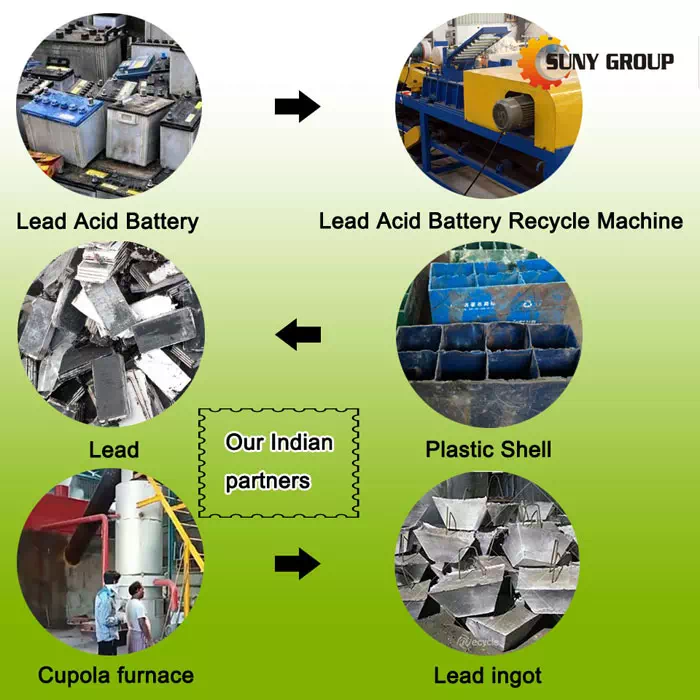

Several Key Processes In The Treatment Of Waste Lead-Acid Batteries

With the increasing number of scrap lead-acid batteries, how to deal with them has become a problem that people generally pay attention to. The advanced process technology in the lead-acid battery recycling process can effectively reduce the energy consumption in the processing process, minimize pollutant emissions, and improve the resource recovery rate. Therefore, innovating some key technologies and processes to improve the level of clean production in the entire industry can propose feasible solutions for energy conservation and emission reduction. The following are several key processes in the treatment of waste lead-acid batteries:

1. Crushing separation and water medium sorting

Manual dismantling and manual sorting are not only extremely inefficient, but also seriously pollute the site and air. The purpose of resource recovery, energy saving and consumption reduction can only be achieved by mechanically crushing and sorting the whole waste battery, and cleaning the separated waste acid, grid, lead paste, waste plastic and waste separator. .

2. Two-stage crushing

Two-stage crushing and magnetic separator ensure safe and reliable crushing. First, a hammer-type pre-crushing closed operation, in which water is continuously injected to clean plastic parts, prevent dust and maintain a constant temperature in the crusher. After the first stage of crushing, the battery fragments enter the second-stage crushing system. Similar to the first stage, it is also a fully enclosed operation. After the second stage crushing, the size of the battery fragments is reduced to less than 30mm

3. Separation

The two-stage broken pieces first separate the lead mud, large pieces of plastic and lead grids. Lead mud with a particle size of less than 1mm (containing lead oxide, lead dioxide, lead sulfate, metal lead and other fine particles) is separated from lead grids and plastics with a diameter greater than 1mm under the action of water washing. The separated lead mud is sent to the sorting desulfurization system after precipitation and dehydration.

Lead-acid-battery-recycling-process

3. Water medium sorting

The separated lead grids and plastics are sorted by water medium, and lead grids, PP (polypropylene) and heavy plastics are sorted out. The first separation of the above three substances is carried out by water flow control, PP (polypropylene) has the lightest density, floats on the top, and is separated by a screw conveyor, and the metal lead that sinks in the lower part is also selected. The mixture of the remaining heavy plastics and water is separated and dehydrated. The dehydrated water will be recycled in the separator, and the excess water will be returned and screened for recycling. The dehydrated heavy plastics are separated again to ensure that the lead content is kept to a minimum. After the heavy plastics are dehydrated, they are collected and stored. The metal lead deposited at the bottom is separated by water medium, which avoids the lead poisoning of workers in the production process and reduces the labor intensity of workers. On the other hand, separating the grid material and lead mud improves the lead grade of the charge, thereby reducing the amount of flue gas, waste slag and soot, reducing energy consumption, improving metal recovery rate, work efficiency and production capacity, which is conducive to environmental protection.

4. Chemical desulfurization

There is a certain amount of lead sulfate in the selected lead paste. To completely reduce the lead in the lead sulfate, the furnace temperature must be above 1200 °C, which not only consumes energy, but also evaporates a large amount of lead into the flue gas. The lead mud can be smelted after desulfurization treatment. The chemical desulfurization method is realized by the reaction of sodium carbonate and lead mud, which can not only remove the sulfuric acid in the lead mud, but also obtain chemical by-products, which is worth recommending.

The above are some relevant introductions about the recycling and reuse of scrapped lead-acid batteries. SUNY GROUP has rich experience and technical equipment in solid waste recycling. Not only lead-acid batteries, but also lithium batteries, electronic waste, etc. can also provide customers with a complete set of If you are interested or interested, please feel free to contact us.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231