High Voltage Electrostatic Separator Instruction Manual

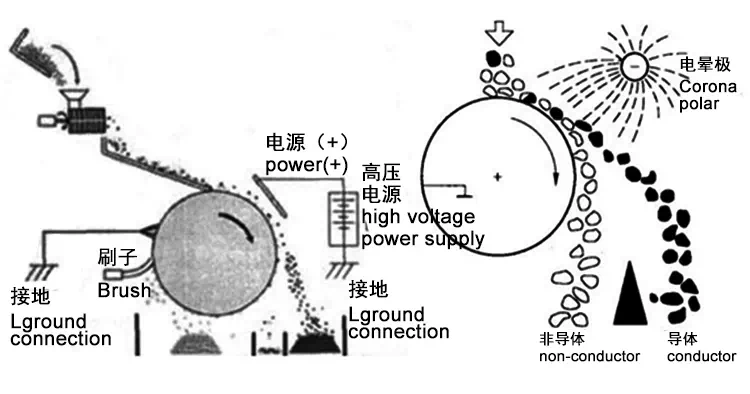

The high-voltage electrostatic separator is a separation device that uses an ultra-high-voltage electric field to charge and separate materials. The main separation materials are conductors (metals) and non-conductors (plastics). Using the difference in charging properties in the high-voltage electric field, the conductors are selected by electric suction and inertial force, and the non-conductors are adsorbed on the non-conductor by using the electric adsorption characteristics of the non-conductor. Rotate the top of the roller and use a brush to pick out on the other side. The separation rate of electric separation can be adjusted according to the actual situation (such as material characteristics, the cost performance ratio of production capacity and separation purity, the uniformity of material particles, etc.), and theoretically it can reach more than 99.5%.

Principle of electrostatic separator

Boot preparation

Check

1. Corona wire, open the observation window, check whether the corona wire is normal, the corona wire is required to be not broken, and at the same time, it is tight without slack;

2. For the transmission belt, open the side door and observe the tension of the transmission belt. If the belt is loose, you need to adjust the tensioner to make the belt tight

3. Insulation baffle. For most materials, the best distance between the insulation baffle and the rolling roller is 6cm. According to the customer's own material situation, adjust the distance. In general, the same batch of materials, the angle of the insulation baffle can be adjusted only once ;

4. The grid distance is measured with a tape measure on the front observation window of the equipment. The best distance for most materials is 16cm for the first time. Adjust the distance according to the material situation.

Boot up

1. Start the electrostatic generator, and the voltage can be adjusted to 80-85 at the usual distance of 16cm from the power grid.

2. Start the rolling roller, the initial starting speed is 300-400 is the best, it can be adjusted according to the material;

3. Start the vibration motor in turn - the air lock motor - the lifting fan

3. The device is turned off

Shutdown sequence is material lifting fan - air lock - vibration motor - rolling roller - high voltage electrostatic generator

!If you need to adjust the electrostatic network immediately after shutting down, you need to manually discharge or wait for the device to discharge naturally after standing still for 3-5 minutes.

High voltage electrostatic separator

Troubleshooting

1. There is no discharge from the discharge port before and after static electricity. a. Check whether the hopper is working and whether the material is blocked; b. Check whether the electrostatic generator is working, the voltage adjustment display, and the physical feeling can be tested. (Explanation: When the material is blocked, there must be no material discharge. When the static electricity does not have high voltage, the material cannot be charged, and the material will not be sucked out or stick to the roller, and will only circulate in the middle warehouse)

2. Static metal outlets contain plastic. a. Adjust the rotation speed of the electrostatic roller and choose to reduce the speed; b. Check whether the plastic in the metal outlet is not peeled off and the metal is only broken into particles. If it is confirmed, it is necessary to adjust the gap between the fixed knife and the movable knife of the mill and reduce the mesh of the circular vibrating screen number. (Explanation: When the rotating speed of the roller is too high, the centrifugal force of the material increases, and the larger piece of plastic does not have enough adsorption force to stick to the roller and will be thrown out from the metal outlet; if the plastic and metal are not completely peeled off, then when the plastic with metal When one side faces the high-voltage power grid, it will be sucked out by the high-voltage electricity, and when the metal side faces the roller, the material will circulate in the middle warehouse.)

3. Plastic exports contain metal. a. Increase the roller speed; b. Increase the electrostatic voltage. (Explanation: When the speed is low and the centrifugal force is relatively small, the metal discharge is not smooth, and the material may accumulate on the electrostatic roller. When the plastic is covered with metal powder, the metal will be discharged from the plastic outlet; when the voltage is low, the material The charging capacity of the battery becomes worse, and the adsorption capacity of the grid decreases. At this time, the static electricity production decreases, and the metal circulates in the middle warehouse. At the same time, some metals may be carried out by the plastic at the plastic outlet)

4. Static net discharge. When the discharge phenomenon of the power grid is observed, the voltage at this time is high or the electrostatic network is close to the electrostatic roller, and the voltage can be appropriately lowered or the distance from the power grid can be adjusted (discharge will start the protection system of the electric control, causing the static network to be powered off, and at the same time It is possible to break down the insulation board and cause leakage, so it should be adjusted in time)

5. No material discharge. The reason is that the wind lifts and blocks the material, and it needs to be shut down, the pipe cleaning hole is opened, the material is manually removed, and then the production is resumed. (Explanation: a. When the voltage, speed and baffle distance adjustment of the electrostatic separator do not match, it is very easy to cause a decrease in output, and the material circulates in the middle warehouse, so that the unseparated material accumulates and causes the air lift pipe to be blocked. At this time It needs to be dredged manually and the electrostatic separation settings should be adjusted. b. When the material particles are large and heavy, the heavy material will accumulate at the corner of the air lift pipe and block the pipe. At this time, the size of the material needs to be reduced, and it is recommended to be below 3mm; c. Observe the wind lift air locker. When there is too much material in the silo, the air locker material cannot be discharged, which will cause the air locker to block the material. It is necessary to stop the machine in time to disassemble the air locker and clean the materials to avoid greater losses such as motor damage.

6. The silo does not discharge material. Check whether the vibrating motor is damaged and whether the silo spring is invalid, and if confirmed, replace it in time. Explanation: a. The vibrating motor is damaged, the fluidity of the material itself is poor, and the material is difficult to discharge; b. The spring fails, the hopper sinks, the discharge port will be close to the electrostatic roller, and the rubber at the material port will block the material port, causing the material to fail. Discharge; c. Observe the wind-lift air locker. When there are too many materials in the hopper, the air locker material cannot be discharged, which will cause the air locker to block the material. It is necessary to stop the machine in time to dismantle the air locker and clean the materials to avoid damage to the motor. Big loss.

7. The electrostatic roller does not rotate. a. Check whether the belt is tight, if it is too loose, the power transmission cannot be performed; b. The sinking of the silo will increase the rotational load, resulting in the inability to rotate; c. The roller bearing is stuck, because the materials to be sorted are mostly powder, fine If the powder may enter the rolling bearing, it will not be able to rotate. At this time, the bearing needs to be replaced.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231