Operating Instructions for Air Separator

The airflow separator is an airflow separation equipment independently developed by our company according to the different lifting heights of materials with different specific gravity by buoyancy, combined with the characteristics of domestic and foreign equipment, integrated the successful experience of domestic and foreign equipment, and introduced key technologies. The device has the following salient features:

1. Advanced design, novel structure, stable performance, high efficiency, small footprint, low noise and wide application range.

2. The wind direction and speed are adjustable, the adjustment method is stable, and the operation is reliable.

3. The system adopts negative pressure closed-loop operation mode, which can effectively prevent dust from escaping and completely solve the problem of fly ash environmental pollution.

4. For parts that are easily damaged by dust, use a dust filter to isolate the dust and prolong the service life of the equipment.

5. The classification efficiency is high, and the purity of the finished product can generally reach more than 99%. It can be adjusted by frequency conversion to control the vibration frequency.

Scope of use: It is suitable for the separation of various metals and non-metals, suitable for powdery materials, granular materials, mixed materials, and separation and sorting according to their specific gravity, particle size or shape.

Basic parameters

Sieve mesh: 200 mesh

Transmission motor power: 3kW

Fan motor power: 3KW

Transmission type: belt drive

Transmission spindle speed: 500-1200r/min

Mechanical structure and working principle

Working principle of air separation

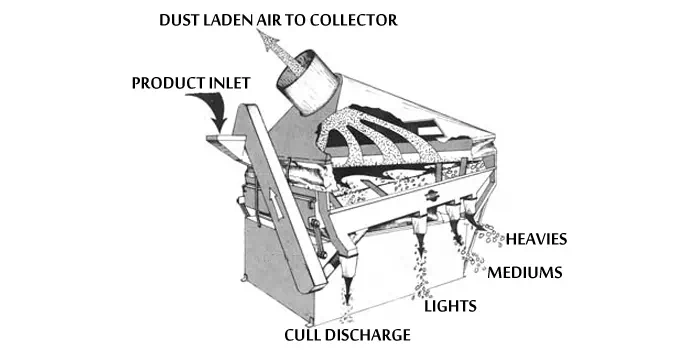

Mechanical structure: The equipment is divided into body frame, fan, transmission motor, eccentric shaft, support rod, silicon steel sheet, air guide valve, screen, wind cover and other parts.

Working principle: The airflow separator produces buoyancy on the materials entering the machine through the wind blown by the lower fan. The materials with different specific gravity or different particle sizes are lifted by the buoyancy at different heights, and the height of the counterweight materials is lower. , the height of the light material is high, and the vibration generated by the eccentric shaft driven by the transmission motor moves the heavy material from a low place to a high place. Because the light material is in a suspended or semi-suspended state, the material will basically not move to the high place. It moves at a high place, and because of the accumulation of materials, light materials are squeezed out of the equipment from the low outlet, and equipment with large specific gravity or large particles flows out of the equipment from the high outlet.

Equipment debugging

1. The equipment discharges normally

(1) The air separator is to discharge materials with heavy specific gravity or large particles at the higher outlet, and to discharge materials with light specific gravity or smaller particles at the lower outlet. The material flows out from the high and low outlets evenly, and the sorted material is not mixed with other materials.

(2) When the material is in the heavy state of the air flow separator, the light material is in a suspended state, and at the upper 30mm of the screen mesh surface, the heavy material flows out to the high material port evenly on the mesh surface;

(3) The plastic-coated cloth on the lower side is in a raised state, and there is tension when touching it with fingers; the plastic-coated cloth on the upper side is in a slightly raised state, and there is no dust and smoke exhaust at the discharge port.

(4) The wind direction of the air outlet of the lower fan is 10-20 cm inward from the outlet.

(5) The equipment has no abnormal vibration and abnormal noise.

2. Abnormal discharge phenomenon

(1) Materials with small specific gravity are discharged from the high outlet. a. The air volume of the lower fan is small, and the light materials cannot be suspended, so that the light materials and heavy materials are discharged from the high discharge port together (at this time, the frequency converter needs to be adjusted to increase the air volume of the lower fan); b. The wind direction of the air valve If the angle is wrong, the light material will be discharged from the high outlet (adjust the wind direction of the air valve, adjust the handwheel, and change the angle of the air valve).

(2) The material with high specific gravity is discharged from the lower outlet. a. The rotation speed of the eccentric shaft is slow, which causes the vibration speed to fail to keep up, and the heavy materials are discharged from the low outlet (adjust the frequency of the transmission motor to increase the motor speed); b. The inclination angle of the screen is not enough, resulting in the light materials being discharged from the high place Discharge from the discharge port (at this time, it is necessary to adjust the angle adjustment bolt of the screen surface to increase the screen angle).

(3) Dust and smoke are discharged from the discharge port. The opening of the air valve on the top is small, and the dust and smoke cannot be removed through the wind cover. The opening of the air valve can be increased by adjusting the handle of the air valve.

(4) The plastic-coated cloth is sunken inward. a. The air output of the lower fan is small. At this time, it is necessary to adjust the fan frequency converter to adjust the fan speed to increase the air volume of the fan; b. The opening of the top air valve is large, and the air valve opening can be reduced by adjusting the handle of the air valve

(5) There is a piece of the screen that is raised from the discharge port. When the tension state of the screen fails, the material cannot protrude from the screen and pass through the material, and the blowing of the lower fan will cause a large amount of loss from the protruding screen, thus affecting the separation efficiency. It is necessary to re-lay the screen (the surface of the screen is flat without obvious protrusions or depressions, and there are no raised steel wire burrs around it).

(6) The eccentric shaft does not rotate. Check whether the belt is tight, if it is too loose, power transmission cannot be performed;

Maintenance and maintenance

1. Regularly check whether the fasteners are reliable.

2. Check the lubrication condition of each bearing, and lubricate the bearing in time.

3. Run for two weeks to check whether the spring and silicon steel sheet are invalid. If they fail, replace the spring or silicon steel sheet.

4. Check the tension of the belt after one week of operation, and then check it twice a week, and adjust it in time if it does not meet the requirements.

5. Replacement of the screen: When replacing the screen, first open the tensioning quick clamp, use the push-pull clamp to open the pressure plate that compresses the screen, then take out the screen and replace it, after the replacement, use the tightening quick clamp to The platen is pressed tightly.

6. Regularly check the insulation of the electrical system and the connection of the terminal. The explosion-proof surface is required to be clean; the cable must be replaced when it is damaged; the terminal must be re-tightened when it is loose.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231