How does e-waste advance precious metals?

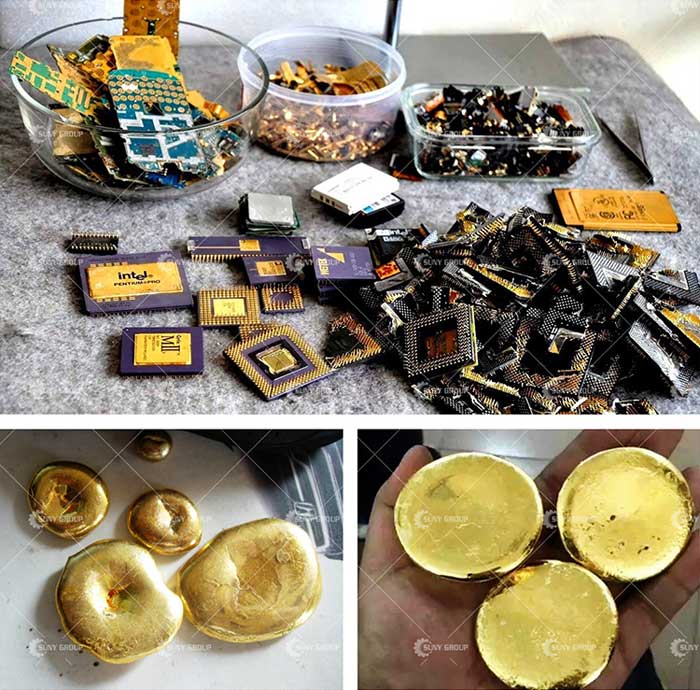

Many scraps contain precious metals gold, silver, platinum, and palladium, but the content varies. Common precious metals containing higher grades and valuable for extraction include:

1. Waste electronic circuit boards. Such as waste computer boards, telecommunications boards, VCD boards, TV boards, etc.

2. Various gold-plated pieces. Such as aviation plugs, gold-plated plug-ins on various electrical appliances, gold-plated electronic components, electronic feet.

Waste circuit boards are disassembled into tin slag, metal components, electrolytic capacitors, integrated circuit chips, chip capacitors, plastic packaging parts, CPU and RAM, and motherboards through automatic disassembly machines. Tin slag and metal components can be sold directly, and electrolytic capacitors are separated into aluminum powder and plastic powder by capacitor recycling equipment, which is also very useful.

For acoustic surfaces containing silver and palladium, metal encapsulated triodes, and integrated circuits, use a special cutting machine to remove the metal shell and punch out the chip. Then, according to the chip and integrated circuit plan, valuable metals are extracted. For electrolytic capacitors with high aluminum content, they have been rolled , Directly smelt metal aluminum after crushing, and extract valuable metals after crushing Zener diodes, some varactor diodes, other glass-encapsulated components, and plastic-encapsulated light-emitting tubes.

Chips, north-south bridges, memory chips, integrated circuits, and plastic encapsulation field effects that cannot be returned after disassembly are all components that contain a higher amount of gold and silver in the collective material that meets the unified treatment, and can be baked with ozone (ozone can completely destroy the formation of combustion Harmful flue gas), the roasting residue adopts solvent carrier, leaching copper, lead tin, hydrochloric acid medium to leaching gold, platinum and palladium, and extracting gold, platinum and palladium. For chip capacitors with high silver and palladium content, the acid method is used to independently extract silver and palladium.

For gold-plated circuit boards and plug-ins, it is recommended to use a non-cyanide environmentally friendly gold stripping agent to quickly strip and extract gold. For acoustic surfaces containing silver and palladium, metal encapsulated triodes, and integrated circuits, use a special pin cutter to remove the metal shell and punch out the chips, and then extract valuable metals according to the chip and integrated circuit plan. For electrolytic capacitors with high aluminum content, they are dry-rolled , After crushing, the metal aluminum is directly smelted. For the zener diodes, some varactor diodes, other glass-encapsulated components, and plastic-encapsulated light-emitting tubes, the valuable metals are extracted after crushing, and the circuit boards are leached with organic acid and subjected to liquid electrolysis. Produce electrolytic copper and palladium-containing circuit boards (the double-sided circuit boards basically contain palladium, and the palladium is used as a copper-plated substrate in the via hole as a wire), then the palladium is leached with acid, and then the palladium is extracted to extract the palladium.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231