Industrial Metal Crusher Helps Metal Scrap Recycling

In today's society, the pace of life is getting faster and faster. In the state of fast-moving consumer goods, a lot of household waste is discarded every day. Such as waste cans, scrap metal sheets, scrap iron slag, Lulu cans, eight-treasure porridge cans, Heqi cans, metal bottles, cans, cola cans, beverage cans, beer cans, red bull cans, paint buckets, moon cake boxes, cans, etc. , and even some outdated bicycles, motorcycles, cars, these are some metal garbage. Due to corrosion, damage and natural obsolescence of metal products, a large amount of scrap metal is produced every year.

If these scrap metals are discarded at will, it will not only cause environmental pollution, but also waste limited metal resources. For this reason, how to rationally use scrap metals makes scrap metal shredders come into being.

Scrap metal recycling

Someone once estimated that recycling a discarded aluminum can saves 20% of the money and saves 90%-97% of energy than manufacturing a new can. Recycling 1 ton of scrap iron and steel can make 0.9 ton of good steel, which can save 47% of the cost compared with smelting with ore, and can also reduce air pollution, water pollution and solid waste. It can be seen that establishing the concept of sustainable development, strengthening the classification and treatment of garbage, recycling and recycling scrap metal has huge economic and social benefits, and metal crushers are indispensable.

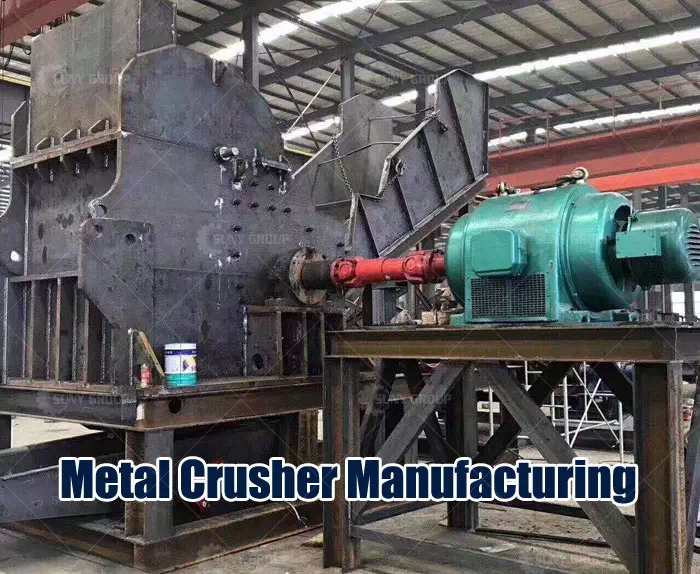

The industrial metal crusher is mainly used for the crushing and processing of scrap metal, in order to reduce the transportation cost of scrap metal and achieve a relatively good profit prospect in terms of recovery price. The main body of the equipment is made of thickened steel plate in structure, and the lining is high manganese. Steel castings are used to protect the outer body, and the machine adopts a disc-type fastening and rotating mechanism at the rotor part of the main engine.

There are several steel discs installed on the horizontal shaft on the rotor (the number and diameter of the steel discs are based on the model). There are 6 pin shafts distributed around the steel disc, and several hammer heads are suspended in the axial direction for hitting and breaking the material. The main shaft is supported by ball bearings, the circulating oil is forced to lubricate and cool, and a temperature sensor is installed to ensure high-speed and stable operation of the equipment. Metal shredders are widely used in scrap steel recycling companies, metal smelting, construction industry, metal recycling industry, automobile recycling companies, etc.

The metal is fed into the forced feeding and crushing port of the equipment through the feeding conveying device, and the metal is primary crushed by the crushing process of the pressing roller and the primary crushing shaft. After the primary crushing, the metal enters the main cavity of the equipment. Driven by the torque motor, the hammers on the rotor of the main machine take turns to hit the objects to be crushed that enter the cavity. The materials pass through the air cyclone sorting system to separate the paint, rust and waste plastics in the metal, and the materials discharged at the bottom of the equipment are transported to the collecting point through the conveying equipment.

Material after scrap metal crushing

In this process, the non-magnetic material contained in the material is sorted and discharged from the production line under the action of the magnetic separator and falls into the non-magnetic material pile. In addition, the whole system is equipped with a dust removal device, which reduces the hazard of dust pollution generated in the production process to a minimum. The equipment mainly has the advantages of high output, low energy consumption, high efficiency, fine and uniform discharge and so on. And when using the equipment, the noise is low, the pollution is small, the operation is simple, and the maintenance is convenient.

SUNY GROUP has rich experience and many cooperative customers in industrial metal crushers. At the same time, it has strong platform construction and scientific research resources to ensure that it can provide customers with complete technical services such as pre-sales consultation, type selection design, testing, on-site guidance and installation, equipment debugging, personnel training, etc. If you have relevant questions or need to consult, Feel free to contact us anytime.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231