Screen Cleaning For Daily Maintenance Of Copper Wire Recycling Machine

The copper wire recycling machine is an environmentally friendly mechanical equipment used to smash waste wires, circuit wires, miscellaneous wires, communication wires, data wires, earphone wires and sort the copper and plastic in them. It is also a waste recycling equipment. Under normal circumstances, we can use it to decompose waste wires and miscellaneous wires that we do not use to achieve effective recycling of resources. If any equipment wants to be used for a long time, regular cleaning and maintenance are indispensable. So, what are the important parts of the copper wire recycling machine that need to be cleaned? When using the copper wire recycling machine, there are two parts that are easy to block, and these two parts are also A place that needs to be cleaned up frequently.

1. Feeding port: Feeding is the main prerequisite for copper rice machining operations. Without the feeding port, it is impossible to complete various operations such as the crushing and processing of waste wires and cables. Because of this, the feeding port will also be blocked when it is used. If the size of the material carried in the feeding port is too large, serious congestion will occur, resulting in a decrease in the feeding speed. Therefore, daily cleaning of the feed inlet is the basic condition to ensure the normal and efficient operation of the machine.

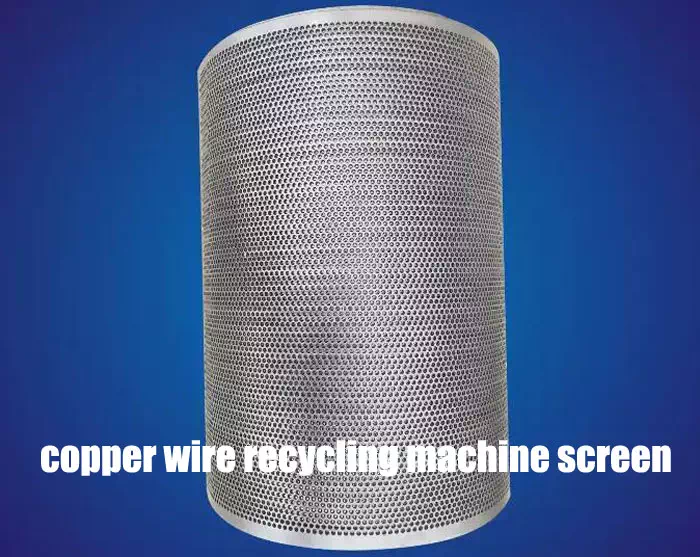

Copper wire recycling machine screen

2. Screen: The screen is the main guarantee for filtering particulate matter and making the copper and plastic processing of the copper wire recycling machine more pure and high-quality. It is precisely because of this that the screen will be extremely blocked after long-term use and work. Therefore, when using the copper wire recycling machine, we need to clean them regularly to clear the blockage of the screen, which is beneficial to the processing effect of the copper wire recycling machine.

3. When the sorting of the copper wire recycling machine is not clean, in one case, the diameter of the waste wire is small, and the copper wire recycling machine can process various circuit wires, miscellaneous wires, communication wires, data wires, etc. Scrap wires such as headphone cables. If the diameter of the processed waste wires is too small, the copper-plastic separation rate of the copper wire recycling machine equipment will be affected, and the separation will be unclean. Secondly, the production and debugging of the copper wire recycling machine is not in place. The installation and debugging of the equipment before the production of the copper wire recycling machine is very important, including the load test of the copper wire recycling machine, which is determined on the basis of the good empty running test.

To sum up, if you want to ensure the long-term and effective work of the copper wire recycling machine, and ensure high-quality and efficient operation, you may wish to pay more attention to the feeding port and the screen, which are easily blocked parts, and clean them daily. to do it for them. SUNY GROUP is a professional copper wire recycling machine manufacturer. It is well received and trusted by customers for its high cost performance and perfect after-sales service. If you are interested or have any questions, please contact us.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231