Lithium battery dismantling and recycling equipment technical scheme

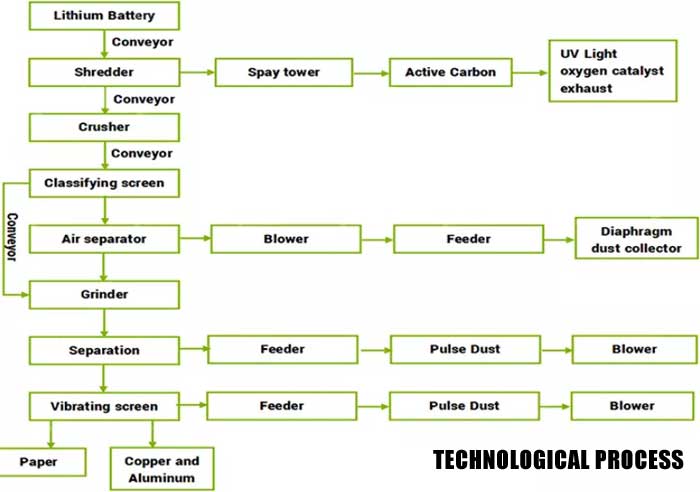

The utility model of lithium battery recycling and processing equipment mainly achieves two purposes in the working process and technological process, one is to crush and recycle waste lithium batteries, and the other is to collect and process a large amount of dust generated in the production process, so as not to cause workplace pollution. environmental pollution, while protecting the health of workers. The equipment of the present utility model and the connection relationship of the equipment are further described below in conjunction with the two circuits of crushing and recycling of waste lithium batteries and collection and processing of dust.

Lithium battery recycling and processing equipment is used in the crushing and recycling of waste lithium batteries: the waste lithium batteries are sent to the feed port of the primary crusher through the belt conveyor for the first crushing, and the materials after primary crushing are sent to the belt conveyor. Machine B3 is sent to the secondary crusher by the belt conveyor for 2 crushing, and the material after secondary crushing is sent to the belt conveyor, which is sent to the tertiary crusher by the belt conveyor for the 3rd crushing. During the conveying process of the material, the iron is removed by the magnetic separator installed on the belt conveyor, and the material that has been crushed for the third time is sent to the feeding pipeline by the high-pressure feeder and further sent to the cyclone dust collector. The material collected at the bottom will be sent to the unloader. Through the timed discharge function of the unloader, the material will enter the vibrating screen, and the waste lithium battery crushed material will be sorted and recycled in the vibrating screen.

In the process of dust collection and treatment of lithium battery recycling equipment: the dust generated after being crushed by the primary crusher is sucked into the cyclone dust collector by the fan through the air duct, and the dust generated by the secondary crusher is also crushed by the secondary crusher. The air duct is sucked into the cyclone dust collector by the fan, and the unloader discharges and collects the coarse and heavy dust collected at the bottom of the cyclone dust collector, such as plastic dust, while the lighter dust at the top of the cyclone dust collector enters through the air duct Pulse dust collector, the precipitation dust collected at the bottom of the pulse dust collector is discharged and collected by the unloader, and the air purified by the pulse dust collector is discharged into the atmosphere by the fan; the top of the cyclone dust collector will be crushed for the third time. The generated dust is directly sent to the pulse dust collector through the air duct for further dust removal treatment; the dust generated by the vibrating screen during the vibration screening process enters the air duct at the top of the vibrating screen and is inhaled by the fan and sent to the pulse dust collector for further dust removal treatment.

So far, the lithium battery pulverized material obtained in the process of recycling waste lithium batteries has been fully recovered, and the dust generated in the process has also been effectively controlled and reasonably discharged, improving the working environment and ensuring the health of workers.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231