Tire recycling waste tire recycling project

The reforms in the field of environmental protection that have been implemented in recent years are being gradually tightened. What to expect from tire disposal? If there is a total ban on the use of scrap tires and car tires. The legislator's position should spur growth in the waste recycling industry, opening new production facilities to modify it. The tire grinding business deserves close attention. A low-cost, simple method of tire recycling requires the use of special equipment. Let's take a closer look at the popular machine types and the production lines formed from them, the characteristics of these units and their cost.

The dual-shaft crusher shreds the tires into chips, the purpose of which is to cut the raw material into pieces no larger than 5x5 cm, and the blades of the mill can process tires for cars, passenger cars and heavy vehicles.

The working principle of the double shaft tire crusher is as follows:

The tires are fed into the raw material receiving chamber. The size of the window allows the entire product to be loaded, the only requirement is to remove the power cord beforehand.

The shaft of the crumb tire shredder rotates in the opposite direction. Hooks placed on the rotor grab the raw material and tear it apart.

The crushed raw material is sieved through a sieve, which is a rotating drum. Particles that exceed the mesh size are thrown into the load chamber for reprocessing.

After the final material is sorted, it enters the conveyor belt and then into the packaging.

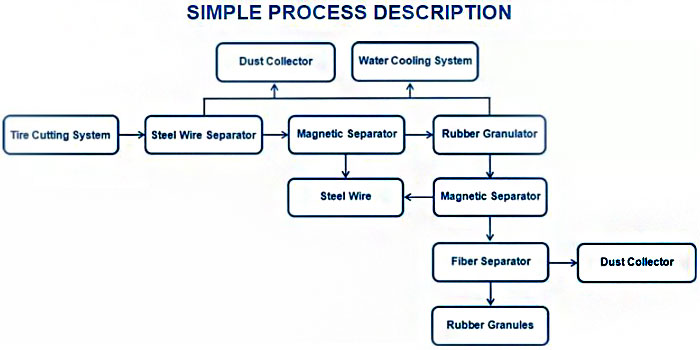

A comprehensive approach to tire recycling is provided through a production line that crushes used tires into crumbs.

The complete sets of equipment offered by the various manufacturers are almost indistinguishable from each other:

1. The device for removing the side ring;

2. Guillotine for cutting tires into strips;

3. Machine for extruding steel wire rope;

4. Rollers for producing rubber crumbs;

5. Magnetic and air separator;

6. Vibrating screen.

The tire processing technology is as follows:

1. Separate tires by weight and diameter to clean coarse dirt.

2. Install the tire in a vise to separate the side ring from the rubber.

3. Cut the resulting rubber into strips about 4 cm wide.

4. The strips are separated into small pieces.

5. Grind the workpiece into chips, and then feed the product into the conveyor belt.

6. Clean the product in the separation chamber. With the help of the magnetic field generated by the device, the particles of the wire rope are separated from the total mass of the chips. In the air cleaning chamber, impurities are finally separated from the rubber granules due to the vortices formed.

7. Sort received products into small and large portions.

8. The finished breadcrumbs are packaged and can be sent to implementation. Larger particles are returned to the conveyor and reground.

In the production equipment market, tire processing lines are represented by manufacturers from different countries. Consider the unique capabilities of each brand of device.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231