What are the devices required in the production line of waste lithium battery recycling equipment

With the increasing demand for lithium batteries in the market, the economic benefits of resource management brought about by recycling and disposing of discarded lithium batteries have become increasingly prominent. The effective recycling of metals such as cobalt, nickel, and lithium in batteries, which are relatively scarce in resources, has gradually become the focus of research by industry insiders.

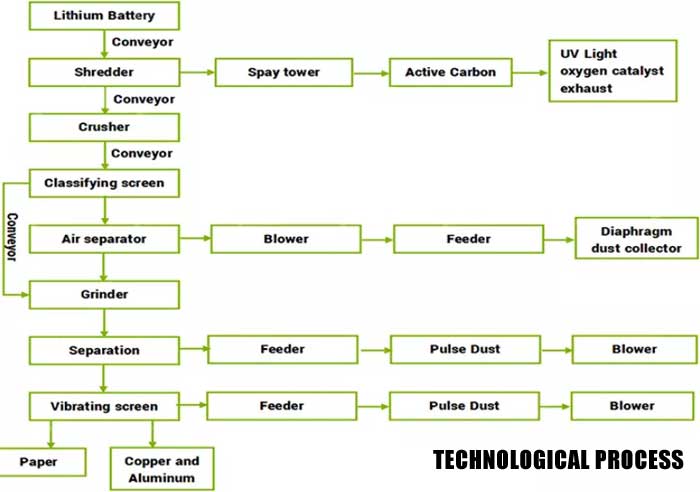

The system devices required in the production line of waste lithium battery recycling equipment include shredder, crusher, magnetic separator, pulverizer, analyzer, sorting device, diverter valve, 3 collectors, 3 pulse dust collectors, 3 high-pressure fans, 3 air separators, 2 induced draft fans and high-pressure fans are connected in sequence to form a complete production line for recycling and processing waste lithium-ion batteries. The power lithium battery sorting production line equipment is equipped with an adjustable three-dimensional inclined vibrating table. The vibrating table is correspondingly provided with a copper particle discharge port, an aluminum particle discharge port and a mixed material discharge port. The vibration amplitude of the table and the three-dimensional inclination angle of the vibration table are precisely adjusted to adjust the friction between the specific larger copper particles and the vibration table, so that the specific larger copper particles are vibrated and crawls to the copper particle discharge port under the action of the friction force. The light aluminum particles move to the discharge port of the aluminum particles under the push of the material, and the materials with similar specific gravity that cannot be distinguished move and crawl to the discharge port of the mixture; then adjust the friction between the specific medium copper particles and the vibrating table, The mixed material discharged from the mixed material discharge port is further refined and the screening process is repeated.

The three-dimensional inclined vibrating table provides a variety of friction and inclination forces for the material according to the characteristics of material friction, gravity, air buoyancy, etc. It greatly improves the sorting purity of materials, with clever design and simple structure. The air flow of the blower in the lithium battery recycling production line can provide upward force for the material particles. The vibration amplitude of the vibrating table can also adjust the friction between the material particles and the vibrating table surface. By adjusting the air flow of the blower and the vibration amplitude of the vibrating table It can finely adjust the friction between the material particles and the vibrating table, and can continuously finely screen and mix copper and aluminum materials until the material screening purity reaches more than 99%.

The above is the relevant introduction of the equipment required for the production line of lithium battery recycling equipment. The recycling of lithium batteries can not only solve the pollution problem, but also produce good economic benefits. As a professional manufacturer of waste lithium battery recycling equipment, SUNY GROUP has rich experience and first-class technical equipment in lithium battery recycling. If you have any questions or problems, please feel free to contact us.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231