Scrap PV solar panel modules processing facility

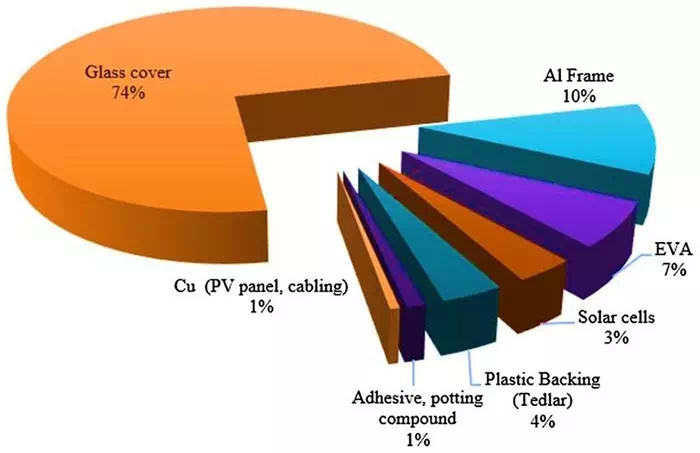

Photovoltaic panel components are composed of photovoltaic cells, aluminum alloy frames, glass covers, sealants, wiring boxes, backplanes and terminal boxes. They can directly convert solar energy into electrical energy, with high conversion efficiency and long service life. However, with the rapid growth of the scale of photovoltaic power generation, a large number of photovoltaic panels will be scrapped every year in the future. If they cannot be effectively processed, it will cause great waste and environmental pollution. For example, silicon, silver, copper, aluminum, glass, etc. in solar panels are all valuable resources, and their recycling can create considerable economic value.

Functions and requirements of waste photovoltaic solar panel module processing facilities:

1. Collection and dismantling of waste photovoltaic solar panel components:

Collection of used photovoltaic solar panel components, including recycling of waste obtained from various sources. Carry out disassembly of battery panel components and separate different materials, such as silicon wafers, glass, metal, etc.

2. Material recovery and reuse:

Recycle and reuse waste photovoltaic solar panel component materials to reduce resource waste. Valuable materials such as silicon wafers, silver paste, aluminum, etc. can be recycled and used to make new solar panels or other products.

3. Hazardous substance treatment: Dispose of harmful substances in waste photovoltaic solar panel components, such as lead, cadmium and other heavy metals. Dispose of hazardous substances in an environmentally friendly manner to prevent harm to the environment and human health.

4. Facility safety and environmental management: Ensure the safe operation of waste photovoltaic solar panel component processing facilities, including employee personal safety and fire safety. Emphasize environmental management, including noise control, pollutant emission monitoring and soil pollution prevention.

5. Compliance with regulations and policy requirements: Comply with relevant laws, regulations and policy requirements, such as waste management regulations, environmental protection policies, etc.

Advanced waste photovoltaic solar panel component processing technology:

1. Mechanical disassembly technology:

Use mechanical devices to automatically dismantle waste photovoltaic solar panel components to achieve rapid and efficient separation and recycling.

These techniques typically include steps such as cutting, crushing, and screening to break down components into different material parts.

2. Efficient sorting technology:

Use advanced sensors and sorting equipment to efficiently sort waste photovoltaic solar panel components.

These technologies can quickly detect and identify the characteristics of different materials, achieve automatic sorting and separation, improve recycling efficiency and reduce resource waste.

Advanced waste photovoltaic solar panel module processing technology has the potential to improve recycling efficiency, reduce environmental impact and realize resource recycling. However, each technology has its specific applicable conditions, advantages, disadvantages, and technical difficulties. Therefore, it is necessary to comprehensively consider different factors and select the most suitable combination of technologies during practical application. Future research and development will further promote innovation and advancement in processing technologies for used photovoltaic solar panel components.

Scale and investment cost of waste photovoltaic solar panel module processing facilities:

The scale and investment cost of waste photovoltaic solar panel component processing facilities will be affected by multiple factors, including processing capacity, technology selection, equipment configuration, regional differences, etc. Here are some general estimates:

1.Scale:

Processing Capacity: The size of a scrap photovoltaic solar panel module processing facility can be measured in terms of the number of scrap panels processed per day or year. Scales can range from hundreds of kilograms to several tons.

Square footage: A facility’s footprint will also be affected by processing capacity and equipment configuration. Generally speaking, waste photovoltaic solar panel module processing facilities require certain factories, warehouses and office areas.

2. Investment cost:

Equipment investment: A major component of investment costs is equipment procurement and installation. This includes mechanical dismantling equipment, sorting equipment, etc. Price and quantity of equipment will vary based on facility size and technology selection.

Construction and infrastructure: Waste photovoltaic solar panel module processing facilities also need to build factories, warehouses, office areas, laboratories, storage areas and other infrastructure. The construction and renovation of these buildings and infrastructure increases investment costs.

Operating Expenses: In addition to the initial investment cost, the operating expenses of the facility also need to be considered. This includes employee wages, equipment maintenance and repairs, energy consumption, waste disposal and emission control, among others.

It should be noted that the specific investment cost will be affected by factors such as regional differences, technological progress and market demand. In addition, factors such as government subsidies, environmental protection policies and market development may also have a positive or negative impact on investment costs.

For accurate scale and investment costs, detailed market research, engineering design and economic assessment are recommended to develop feasibility studies and business plans based on specific circumstances.

Market prospects for waste photovoltaic solar panel module processing facilities:

Waste photovoltaic solar panel module processing facilities have good market prospects in the future. Here are several key factors supporting this view:

Growing solar market:

The solar industry continues to grow rapidly, with more and more solar panels being installed and used. As these solar panels reach the end of their life, the need for disposal will increase.

1. Environmental regulations and policy support:

Many countries and regions have formulated environmental regulations and policies that require the processing and recycling of waste photovoltaic solar panels to reduce the impact on the environment. These regulations and policies provide market demand and support for used battery panel processing facilities.

2. The importance of resource recovery and reuse:

Materials in waste photovoltaic solar panel components, such as silicon wafers, silver paste and aluminum, have high reuse value. Through effective processing and recycling technologies, these materials can be reused, reducing the need for raw materials and promoting resource recycling.

3. Technological innovation and cost reduction:

With the continuous innovation and development of waste photovoltaic solar panel component processing technology, the efficiency and economy of related facilities continue to improve. The introduction of new processing technologies and equipment, as well as the realization of economies of scale, are expected to reduce a facility's costs and increase its competitiveness.

4. Improvement of environmental awareness:

Globally, there is a growing awareness of environmental protection and sustainable development. Waste photovoltaic solar panel component processing facilities can effectively deal with the environmental problems caused by waste panels, and have been recognized and supported by society and enterprises.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231