Solar panel recycling technology equipment

While the spread of solar photovoltaics is seen as an important solution to the transition to renewable energy, what to do with the large number of solar photovoltaic panels when they reach the end of their life can be a challenging issue. Back in 2016, a report by the International Renewable Energy Agency sounded the alarm. According to the agency, photovoltaic panels installed in the early 2000s will need to be removed in the next few years, given that photovoltaics have a lifetime of exactly 25-30 years.

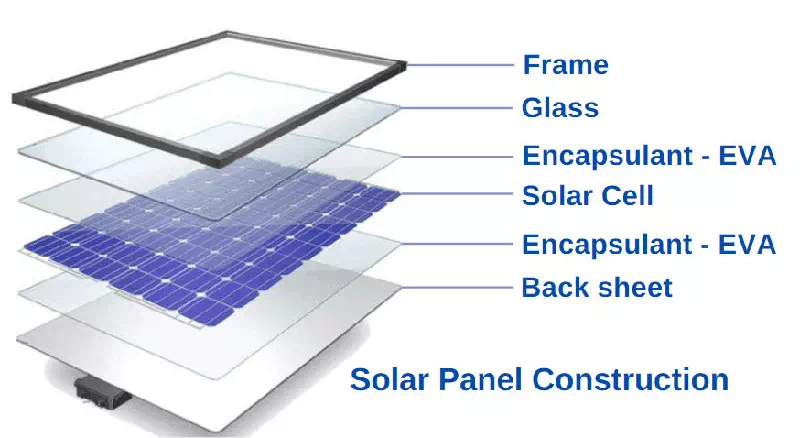

Solar Panel Construction

The complexity of photovoltaic recycling actually depends on the composition of the solar panel modules, which are usually constructed of different materials: a layer of tempered glass on the surface, silicon solar cells that convert solar energy into electricity, and a backsheet at the back. Both sides of the solar cell are also coated with an additional coating, usually consisting of a J-adhesive film (ethylene-ethylene-acetate or EVA), which joins the different components together and protects them from external environmental conditions.

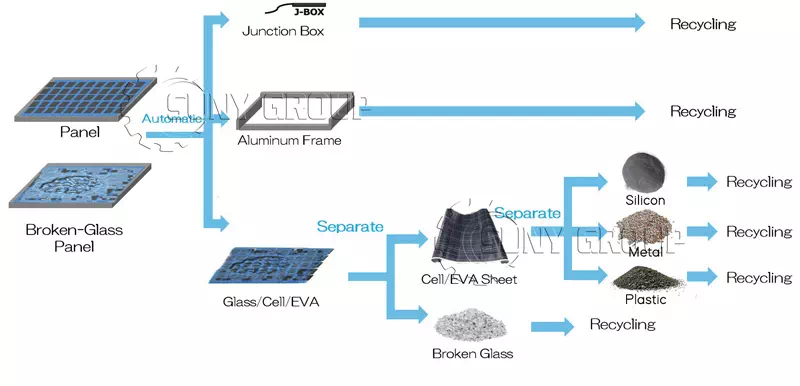

Solar PV recycling typically involves separating recyclable materials by shredding components to gradually reduce their size. The solar photovoltaic panel recycling production line developed and manufactured by SUNY GROUP China can effectively recycle and reuse various solar panels.

Solar PV Panel Recycling Process

In the actual solar panel recycling operation, the lowest technical requirements are the recycling of glass panels and aluminum frames that support photovoltaic panels. This belongs to the "strength work" in the recycling process, and the real "technical work" is Recycling of photovoltaic panels.

At present, the mainstream photovoltaic panels in the world are silicon-based photovoltaic modules, which are mainly composed of tempered glass, ethylene-vinyl acetate (EVA), cells and junction boxes. The role of tempered glass is to protect the main body of power generation, that is, the battery sheet. EVA is like glue to fix the tempered glass and the battery sheet together. The junction box is used as a current transfer station to protect the entire solar panel. With copper wire.

Although from the perspective of material composition, waste solar panels can be said to be treasures everywhere and have great recycling value. However, these materials can be separated one by one and processed separately, but it is a time-consuming and labor-intensive process that also tests technology.

If you want to achieve a truly effective recycling, you must first strip the copper wires, so that the copper can be recycled after purification, and then grind the glass plates from the EVA. The ground glass powder can be reused in industry and construction. . Finally, the silicon in the cell is recycled.

Efficient recycling of photovoltaic modules can significantly reduce global carbon emissions and energy consumption. The researchers pointed out: "So far, a lot of attention has been put on the production of environmentally friendly photovoltaic modules, but efforts to focus on recycling and processing of modules are still limited." "Recycling can not only effectively prevent toxic and harmful substances in photovoltaic products from entering groundwater and soil, thereby having a negative biochemical impact on the environment, but also protecting valuable metallic materials such as silver, germanium, cadmium, and purely energy-intensive materials such as silicon wafers.” So, from this perspective, photovoltaics Recycling can generate a new industrial chain, and PV modules must be refurbished and recycled at the end of their life.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231