Waste tire processing equipment rubber tire pellet production line

Waste tires treated with solid waste have become a treasure granule and rubber powder equipment line. For the environmental protection of waste tire rubber powder equipment, don't worry! The reform and upgrading of waste tire rubber powder equipment is still going on. For waste tire rubber powder equipment If there are higher technical indicators and requirements, Riseke can cooperate to provide relevant technical services to help users solve problems in the recycling and utilization of waste tires, open up the industrial chain of waste tire recycling and utilization projects, and further unblock the tire industry. The purpose of industrial cycle, economic cycle and social cycle.

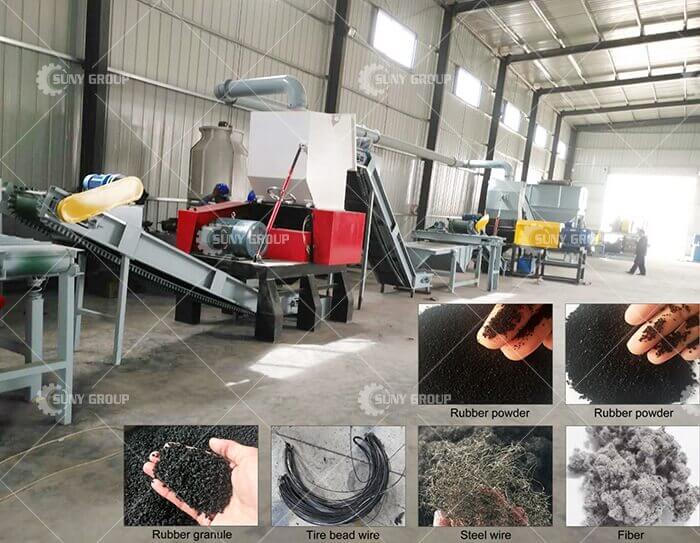

The whole set of waste tire recycling and processing equipment production line has two choices of granule and rubber powder treatment. The range of finished products is 1-6mm rubber granules and 20-60 mesh rubber powder specifications. The complete set of equipment can be configured into different combinations according to the needs to meet the corresponding process requirements and production scale needs. At present, there are two process selections of semi-automatic waste tire processing equipment and fully automatic waste tire processing equipment. Finished products that can meet different production capacity and application routes.

Generally, the equipment for recycling and processing waste tires is composed of fully automated environmental protection equipment such as tire shredders, waste tire shredders or waste tire recycling production lines. For the production and processing of rubber particles, the principle is mainly: the principle of shearing + crushing + vibration screening. Equipped with wire separator, rubber granulator, vibrating screen separator, fiber extraction magnetic separation system. The recycling production line for the production and processing of rubber powder is to use the principle of grinding + multi-stage grinding and screening. Configure conveyor, glue breaker, dust removal system.

The entire production line operates at room temperature, with reasonable and compact layout, small installation footprint, labor saving and high efficiency.

Process flow:

The waste tire processing equipment consists of tire cutting machine, automatic slitting machine, tire cutting machine, rubber breaking machine and auxiliary equipment. First, use a tire cutting machine to decompose the waste tire into two parts from the middle of the tire crown; then use an automatic slitting machine to cut the slitted tire into strips (the width is adjustable), and put it into a tire cutting machine at the same time. The blocks are carried out synchronously; then it enters the rubber breaking unit, and while the rubber blocks are crushed and ground, the capillary steel wires and fibers are separated to obtain pure rubber powder/granules.

The above is the process flow of the entire waste tire processing equipment. The waste tire processing equipment, tire shredders, rubber mills, etc. developed and produced by SUNY GROUP Co., Ltd. all adopt the normal temperature treatment process. The production of rubber powder is not high temperature, non-carbonized, and there is no waste and waste gas discharge during the period, which meets the requirements of environmental protection treatment. Welcome to all places Customers visit the factory to discuss cooperation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231