What is the operating process of the single shaft shredder?

Single-shaft shredders can generally be used to shred hard-to-break plastics, rubber, tires, nylon plastics, car bumpers, discarded fishing nets, plastic pipes, fibers, paper, electrical components, cables, and circuit boards, depending on the blade type. , wood, etc.

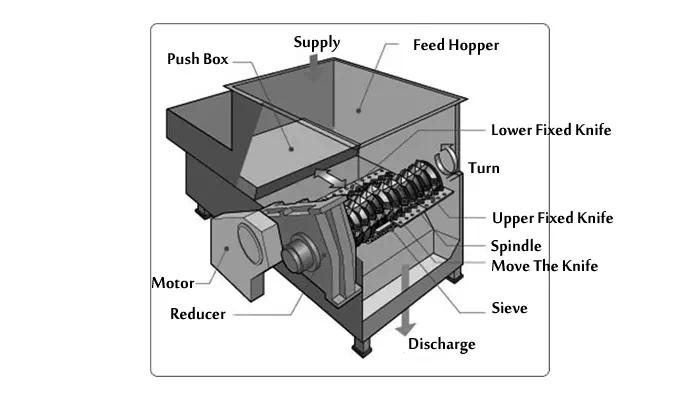

1. Structural function

The single-shaft shredder consists of a moving cutter disc and a fixed cutter to complete the function of shredding materials. The cutterhead is composed of a base shaft and several moving cutter blocks in the shape of a quadrilateral. The moving knife block has 4 cutting edges, which can be replaced. The moving cutter blocks are arranged in V-shape or helical rows along the base shaft, and are fixed on the base shaft with screws, and rotate together with the base shaft to form a moving cutter head. There is one set of static knives fixed on the frame. The material is pushed by the horizontal hydraulic cylinder to feed towards the cutter head. The speed is stable and adjustable, and the propulsion force is large and uniform. It is suitable for recycling various bulk solid materials, irregular and difficult-to-handle materials, plastic containers and barrels, tubes, films, fibers, paper, etc.

Single shaft shredder structure

2. Installation location

Connect the power supply and zero line, connect other power sources, first try to start each part manually to ensure that each part can work normally when manually started, and then switch to automatic start.

3. Operation process

Preparations before the operation of the single-shaft shredder: carefully check whether the power supply of the shredder equipment is damaged, whether the grounding device is good, and prevent electric shock accidents; there is no obvious movement between the adjustment seat and the rack ear seat, which should be eliminated in time; Open the chamber of the knife and the crushed material bin to check whether there are residual plastics and other foreign objects. If there are foreign objects, they should be cleaned up in time; check whether the protective device is in good condition and stop the operation immediately.

The safe operation of the single-shaft shredder and the details of the process are detailed: No-load test drive, turn on the power, start the equipment, and carefully check whether there is any abnormal sound in the operation of the audio-visual equipment; after confirming that the equipment is operating normally, it can be started; then put in the materials to be shredded , When shredding materials, put in new materials after the materials in the knife chamber are completely broken; it is strictly forbidden to put too much material at one time when shredding materials, which will cause jamming and burn out the motor; when the equipment is running, it is strictly forbidden to put your hands into it. Operate in the shredder to avoid injury; it is strictly forbidden to put hard objects into the crusher to cause damage to the blade; it is strictly forbidden to place water bottles, scissors, blades and other sundries on the equipment to prevent foreign matter from falling into the feed port and being damaged equipment; once the blade is stuck, the equipment must be shut down immediately and the power supply must be cut off before processing; only after the fault treatment is completed, the equipment can be restarted.

Single Shaft Shredder Shaft

After the material is shredded, turn off the switch and cut off the power; open the knife chamber and the crushed material bin, and clean up the remaining materials in the crushed material bin; put the shredded materials into woven bags by classification; the staff will clean them up in time The equipment and the surrounding ground are hygienic; the operating parts are regularly lubricated and maintained.

The above is the relevant operation introduction of single-shaft shredding. If you have this demand, please feel free to contact us for consultation. We will customize and manufacture the shredder according to your needs. At the same time, you can also bring materials to test the machine to see the real Effect.

4. Normal maintenance

① Lubricate the main engine bearing every 8 hours. Grease type 2#/3#

② Check the cutter screw twice a day to ensure that the screw is not loose

③ Regularly observe the screen, twice a day to ensure that there is no material blockage

④ Check the hydraulic oil tank once a week to ensure that the oil tank is full and the oil level should not be lower than the position of the filter element, and check whether the oil pipe is leaking

⑤ Grease the motor every day, grease type 2#/3#, clean the fan blades, check whether the screws are loose

⑥ Check the tightness of the V-belt every day, if there is any looseness, adjust the position of the motor to tighten the V-belt

⑦ Add gear oil to the reducer, the gear oil type is No. 220, the oil level must not be lower than the center line of the oil gauge, check whether the fastening bolts are loose every day, check the oil level of the pump station, and the hydraulic oil type of the pump station is No. 46.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231