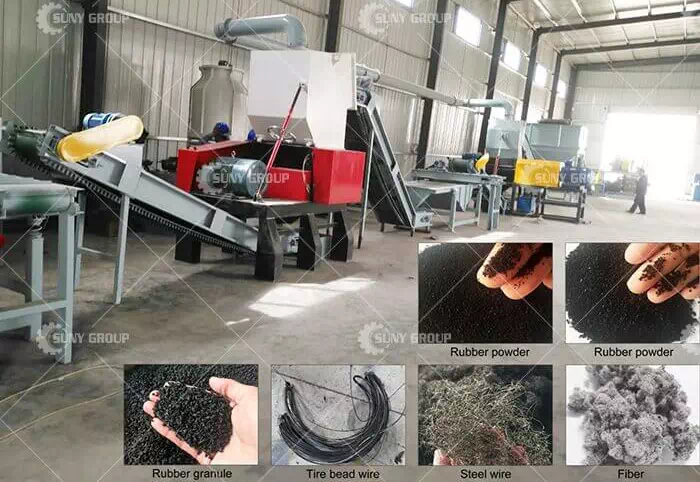

Equipment of Processing Scrap Rubber Materials

Waste rubber, particularly waste tyres, contains steel wires, fibres, and multi-layered composite structures. It must undergo systematic processing through graded treatment to achieve efficient recycling. Current waste rubber processing lines typically comprise multiple stages, including crushing, pulverising, sorting, and fine grinding. By progressively reducing material size and continuously removing impurities, the process ultimately yields high-purity rubber granules or rubber powder. Depending on the intended applications, processed materials can be utilized in recycled rubber products, rubber flooring, sports surface materials, or as rubber modification fillers, enabling high-value resource utilization.

Core Equipment and Functional Configuration

Equipment of Processing Scrap Rubber Materials

The production process commences with primary treatment via twin-shaft or four-shaft shredders, which break down entire waste tyres into smaller, manageable chunks for subsequent processing. Subsequently, the material enters the granulation or pulverisation stage. Rubber pelletisers or pulverisers utilise high-speed rotors and wear-resistant blades to further cut the rubber into uniformly fine particles.

While reducing particle size, sorting equipment plays a critical role. Magnetic separators efficiently remove steel wire impurities, ensuring extremely low metal content in the rubber. Air classification systems utilise airflow to separate lightweight fibres, effectively separating rubber from fibrous materials such as nylon and polyester. Through multi-stage sorting combinations, finished product purity is significantly enhanced, laying the foundation for subsequent fine processing.

Advanced Processing Systems and Production Lines

For applications requiring higher value-added products, production lines can be equipped with additional fine grinding equipment or pulverisers. These further process rubber granules into fine powders, meeting the production demands for rubber modification materials, sealing compounds, and high-end rubber products. Certain systems can also incorporate extrusion or moulding equipment, enabling direct utilisation of recycled materials.

Based on client requirements, our production lines typically adopt two configuration models: - Two-stage systems comprising shredders and pelletisers, suitable for producing rubber blocks or fuel-grade products; - Three-to-four-stage systems incorporating additional multi-stage pulverisation and fine grinding equipment, capable of producing steel-free, high-purity fine rubber pellets or rubber powder. The multi-stage automated design not only enhances resource recovery rates but also ensures consistent particle size and uniform product quality, providing a reliable equipment solution for the large-scale reuse of waste rubber.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231